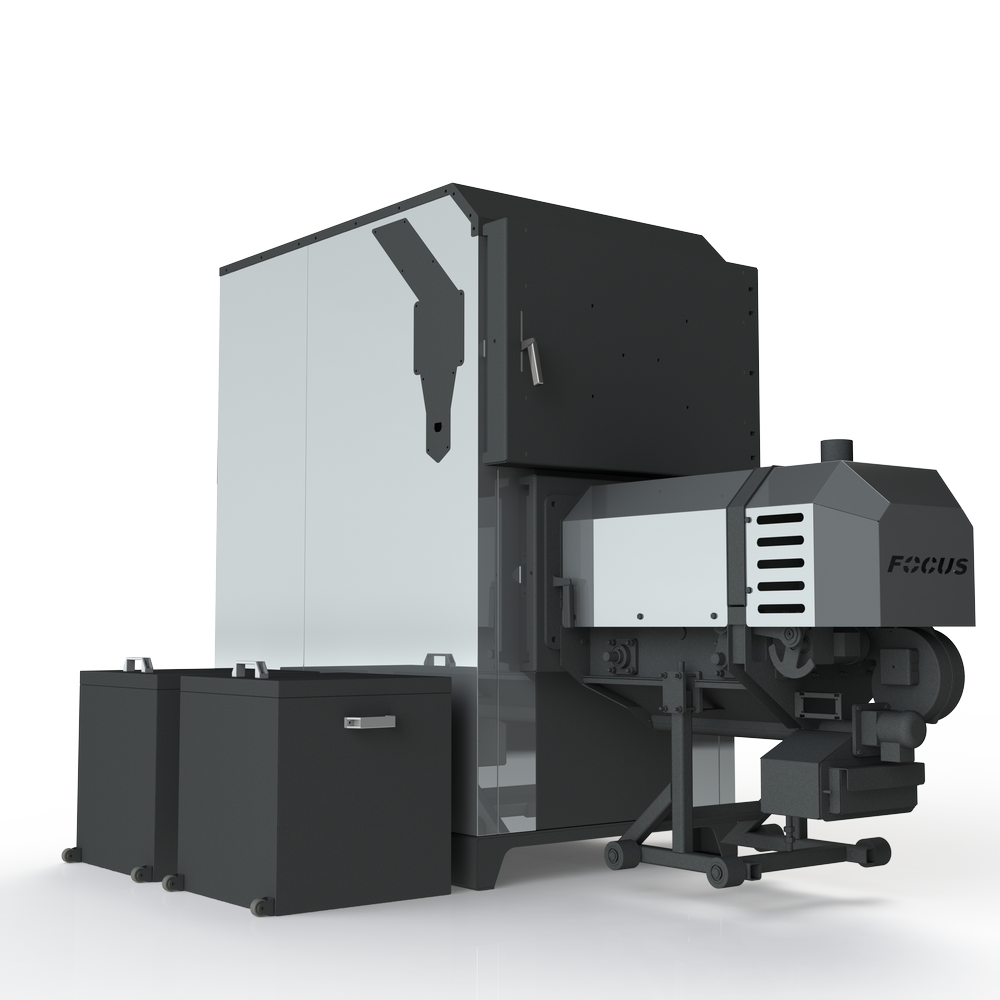

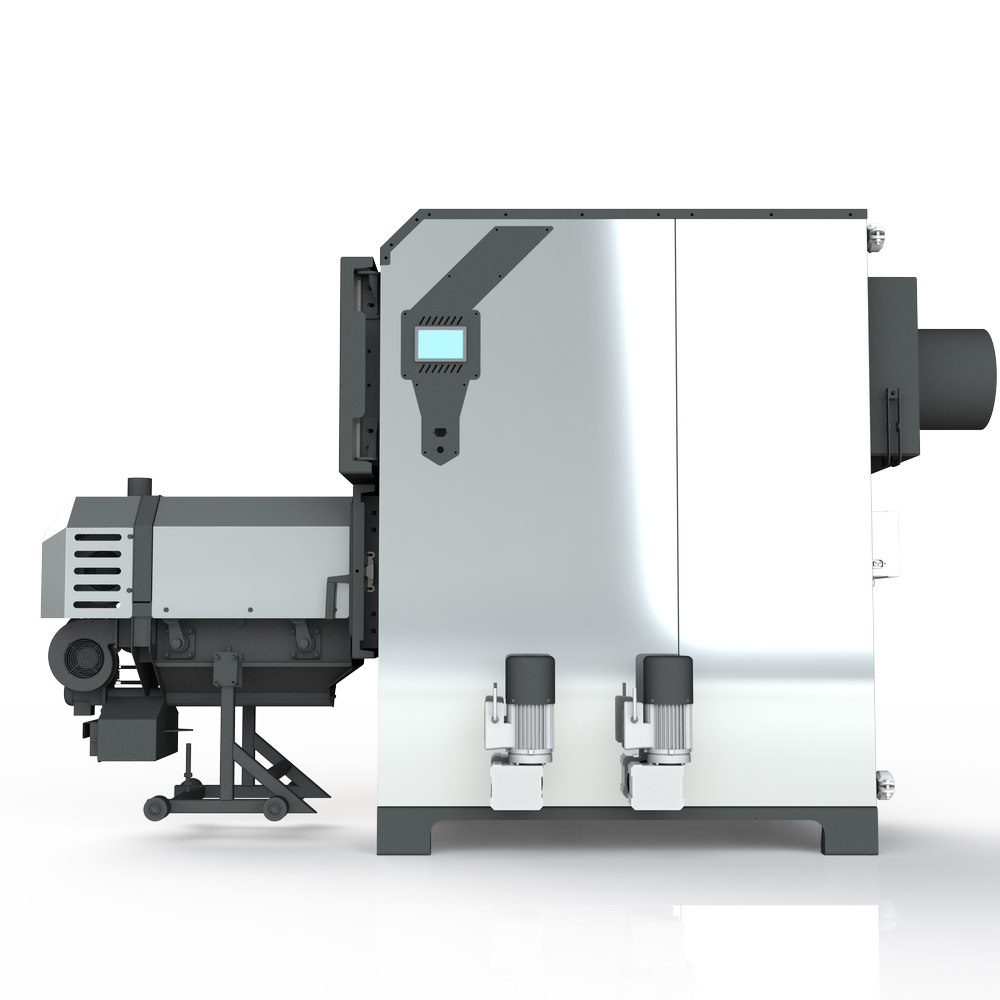

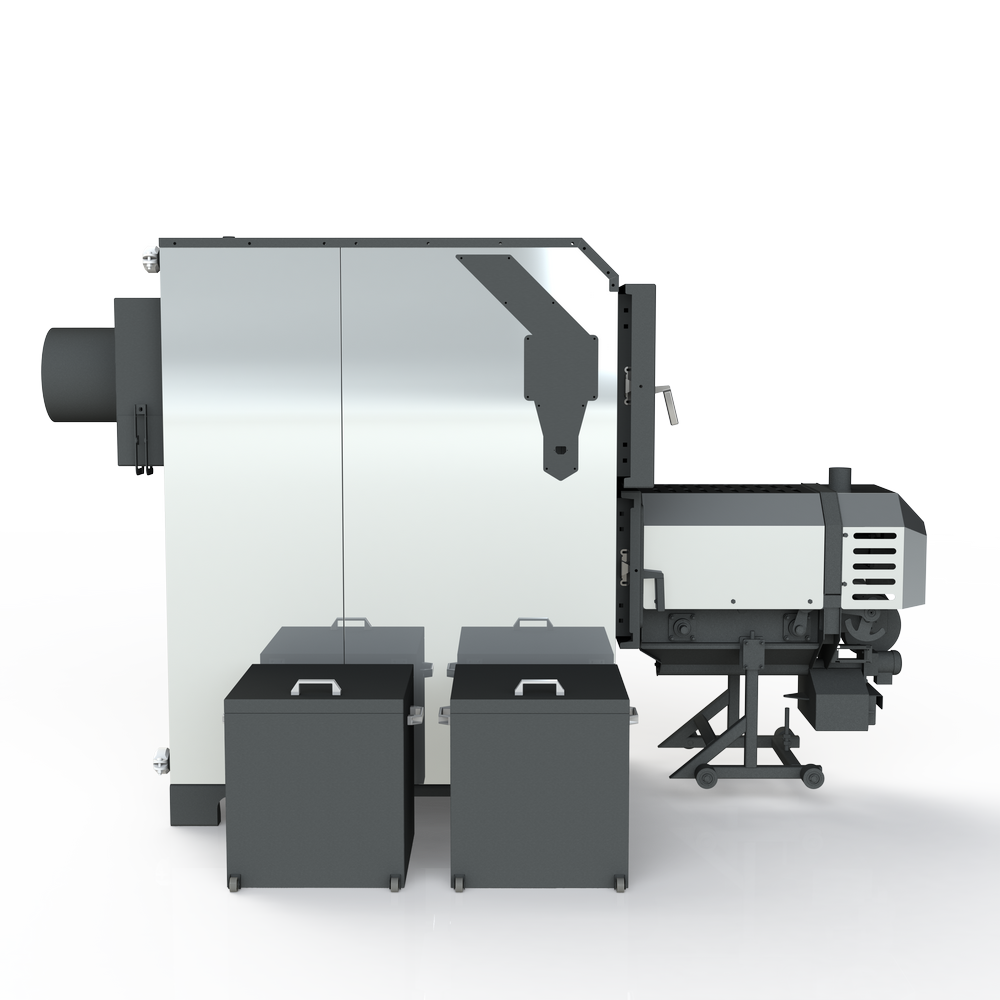

Automated pellet boiler 300 kW FOCUS with built-in industrial pellet burner, built-in screw ash removal system.

The FOCUS automated pellet boiler is designed for uncompromising operation as a single unit. The main emphasis in the development and production of the boiler is on the efficiency of heat removal specifically when working with a flare pellet burner on high-ash (agro) pellets - as the basis for the economic feasibility of purchasing and payback on equipment, reduction of manual labor for cleaning the boiler, increasing the periods between cleanings, convenient removal of ash into roll-away containers.

Main advantages :

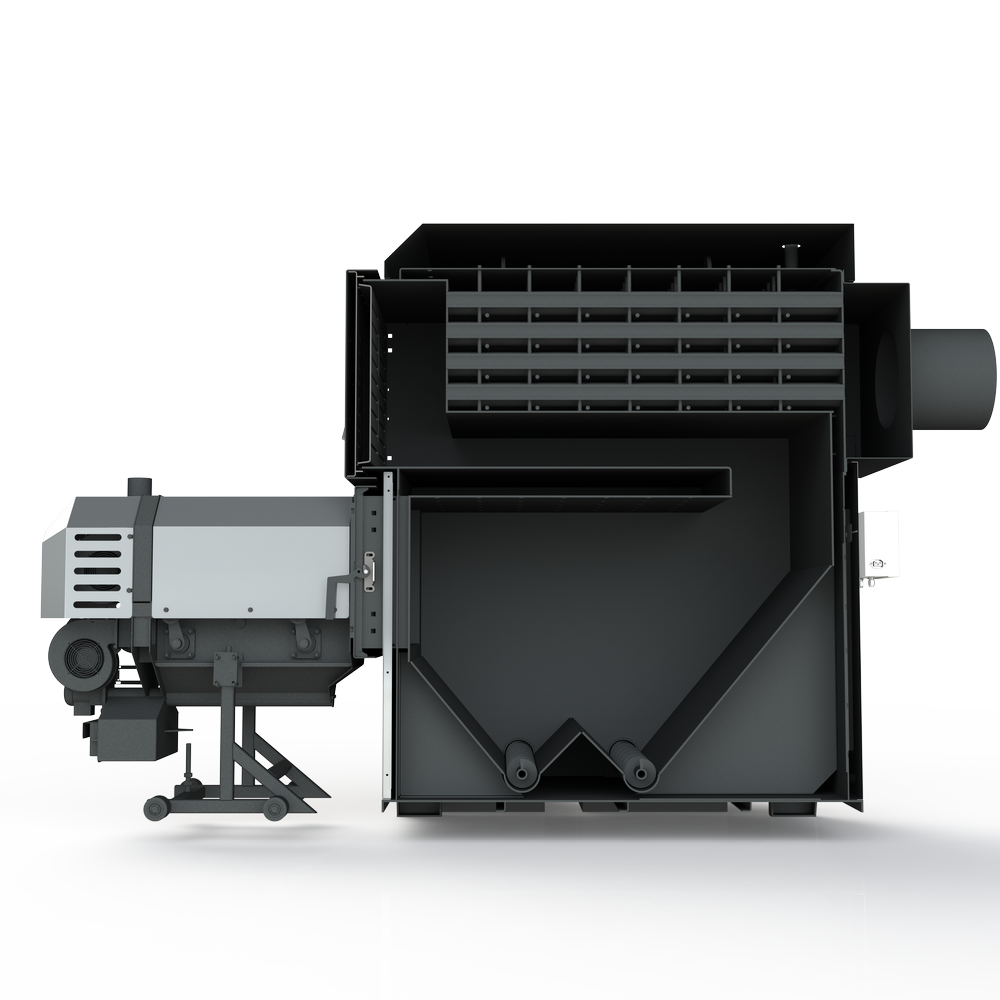

— Maximum ashpit for operation on high-ash fuel;

— Built-in system for auger ash removal from the boiler ash pan;

— Built-in sliding containers for collecting and removing ash;

— Built-in system of auger ash removal from the burner grate space into the boiler ash pan;

— The pellet burner is cleaned into the ash pan of the boiler, and through the screw ash removal system into external containers;

– Hybrid structure of the heat exchange part of the boiler, taking into account the infrared radiation of the burner flame:

— The area for removing the primary thermal stress of the torch (there is no area for the point effect of the torch on the heat exchanger structure) – it simultaneously plays the role of settling heavy particles of the volatile component of the torch, working as an ash filter;

— The convective part of the heat exchanger is maximally developed in combination with a highly efficient horizontal heat exchanger;

- Thoughtful convenient maintenance of the heat exchanger (wide hatch, horizontal cleaning, ash chamber in front of the chimney);

— The ash pan of the high-capacity boiler is designed to work in industrial conditions. With the right selection of equipment, even on high-ash pellets;

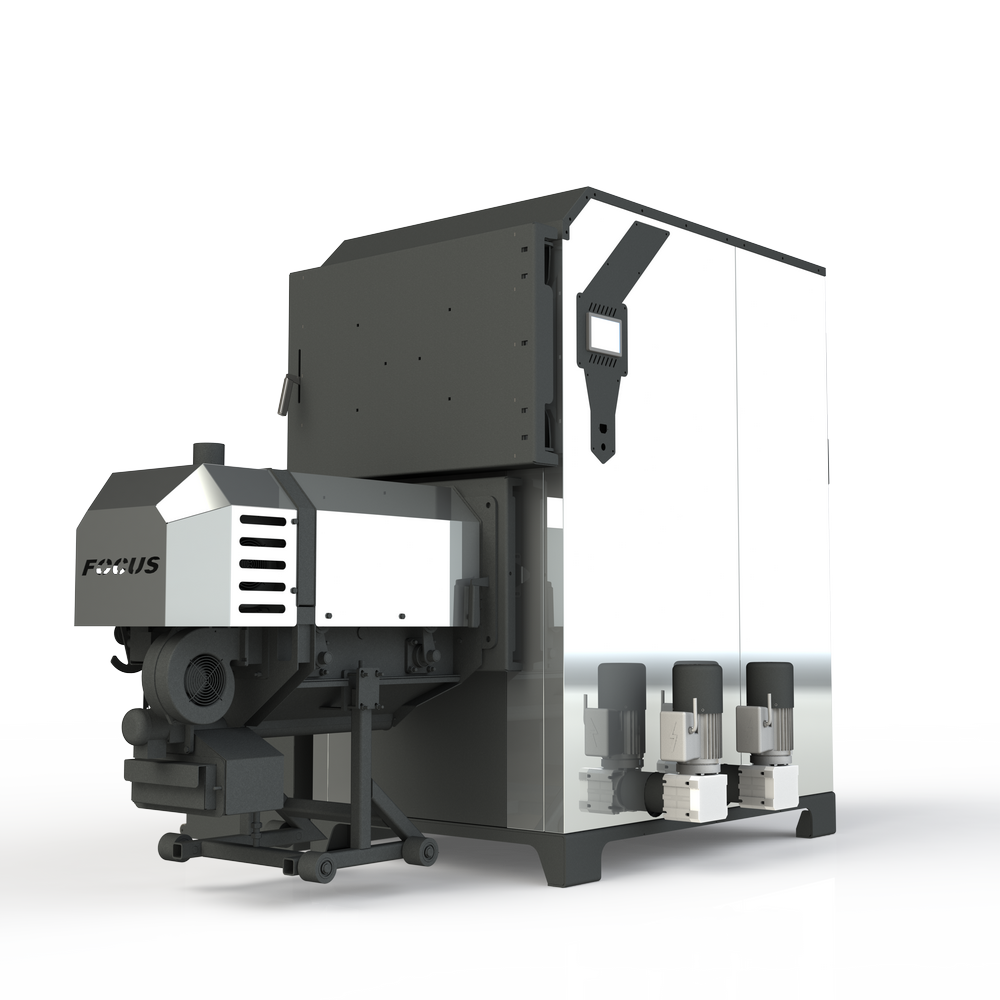

— Location of the boiler door on a pellet pre-firebox in a sliding version;

– The boiler is additionally (at the request of the customer) equipped with a ready-made piping of a three-way or four-way valve with IMP Pumps pumps. Which, in combination with control automation, provides protection against cold return from the heating system and the absence of condensation in the boiler. This, in turn, on the 30% increases the efficiency in comparison with a similar boiler without return protection and on a cold system (when the return is below 40 * C). There is no need to select mixing equipment and coordinate with boiler automation;

- For ease and speed of installation - the boiler is equipped with a Victaulic quick connection system (Victaulic connections, they are Gruvlok). For operational work, guaranteed high-quality connection (does not require symmetrical tightening as a flange connection, no welding work is required at the installation site), allows for slight distortions during installation (up to 2-3 *), which gives freedom to the installer in case of deviations of the room from the design dimensions. Complete with a copper there are couplings and branches under welding or carving connection (it is specified at the order).

- The boiler and the connection system are designed for assembling a boiler house according to the cascade type, when all the power is not initially required (for example, during the construction of a large facility), and when there is a need to increase the design capacity - several boilers with a total capacity of up to 2.2-2.5 MW are painlessly added. At the same time, the presence of three-way valves on each boiler and a hydraulic switch in the heating system disconnects the idle boiler from the flow without restricting the flow of the system and without cooling the coolant through the heat exchanger of the idle boiler.

— Boiler material – structural steel 09G2S. The thickness of the walls of the heat exchange part (furnace and primary heat exchanger, shells) is 6 mm. The thickness of the outer shell of the water jacket of the boiler is 4 mm.

- Thermal insulation - basalt mineral wool 50mm thick.

– Boiler casing – polished stainless steel AISI201

— Adjustable hinges and locks for fine-tuning the tight fit of the ash pit door and heat exchanger to the opening.

- Possibility to change the opening side of the doors.

— Removable roll-away containers of the boiler auger ash removal system.

— Automatic cleaning of the burner into the general ash removal system of the boiler;

- Hybrid plate and fire tube heat exchanger. Where the lamellar stroke relieves the stress of the torch and precipitates the bulk of heavy particles, which is especially important when working with high-ash or agro pellets.

- The most developed convective fire-tube part of the heat exchanger really corresponds to heat exchange.

— Large door for easy access and complete cleaning of the heat exchanger surfaces.

Pellet burner TM "FOCUS"installed in this kit will work both on clean wood pellets and on agro-pellets with ash content up to 10% (pellets from seeds, corn, buckwheat, rice, furniture, straw).

Burner advantages:

— Automatic ignition (2 ceramic FKK candles are installed for contactless air ignition of pellets);

- Screw for supplying fuel to the combustion chamber of the burner;

- Built-in temperature sensor of the burner auger (safety, automatics will turn off the fuel supply with an emergency signal).

- Built-in infrared flame sensor, for fixing and controlling the level of flame radiation (safety, automation detects the presence and absence of a flame using appropriate behavior algorithms);

- Selected proportions of primary and secondary air, for the proper organization of fuel combustion;

- Highly reliable crank drive - moves the grate;

— Type-setting grate for auto-cleaning of the burner. Type-setting elements from heat-resistant grade of chromium cast iron ChKh32;

— The combustion chamber of the burner is lined with refractory bricks, serves as a catalyst for afterburning ballast gases, increases the efficiency of heat generation by the burner (increasing the flame temperature);

– All models of flare burners have a “break” in the fuel supply line, ensuring the safety of equipment operation;

— Controllerallowing you to easily configure the equipment;

- Internet connection module as an additional option - convenient for remote configuration and control of the burner, creating statistics on fuel consumption, errors, power graphs, temperatures, etc.

Functions and equipment

Functionality of the pellet boiler 300 kW FOCUS (80-350 kW):

- power adjustment within 80 kW - 350 kW;

- 5 basic security levels;

- automatic operation: ignition, extinguishing, auto-cleaning in the operating mode, cleaning from the main ash when extinguishing;

- automatic screw ash removal into external ash containers;

- automatic cleaning of the burner into the general ash removal system of the boiler;

- ceramic spark plug, duplication of spark plugs;

- low power consumption (800 W);

- PID-regulation (the possibility of precise control of the burner using an analog control signal, including within the framework of "smart home" technology);

- movable cast-iron grate for mechanical cleaning of the burner;

- pump control (hot water treatment and heating);

- work with room thermostat and internet module;

- work with weather regulation;

- built-in ash filter.

The pellet boiler complies with GOST 32452-2013 (EN 15270: 2007). Provided with 18 months warranty.

Contents of delivery:

- Pellet boiler 300 kW complete with burner and auger ash removal system;

- rolling ash removal container - kit;

- EcoNet internet module;

- weather sensor;

- smoke gas temperature sensor;

- boiler return temperature sensor;

- feeding screw conveyor - 2 m;

- corrugated PVC pipe - 1 m;

- pellet burner controller;

- documentation.

Equipment for pellet boiler rooms

Devices and modules that increase the level of autonomy of the heating system:

- piping kits with a three-way or four-way valve integrated into the boiler control system;

- bins for storage and feeding of pellets;

- room touch EcoSter regulator;

- additional temperature sensors.

Consult our specialists on the features of the deployment of heating circuits and connections.

Dimensions (edit)

Listed in each position separately.

Chimney diameter

Requirements for the boiler room

When designing, you must adhere to the requirements:

- MDNAOP 0.001.26-96;

- DBN B.2.5-XX: 20XX;

- SNiP 2.04.05-91 "Heating, ventilation and air conditioning";

- SNiP II-35-76 "Boiler plants".

Interesting to read

Pellet burner operation process in detail

Which solid fuel boiler to buy for production

Reviews

There are no reviews yet.