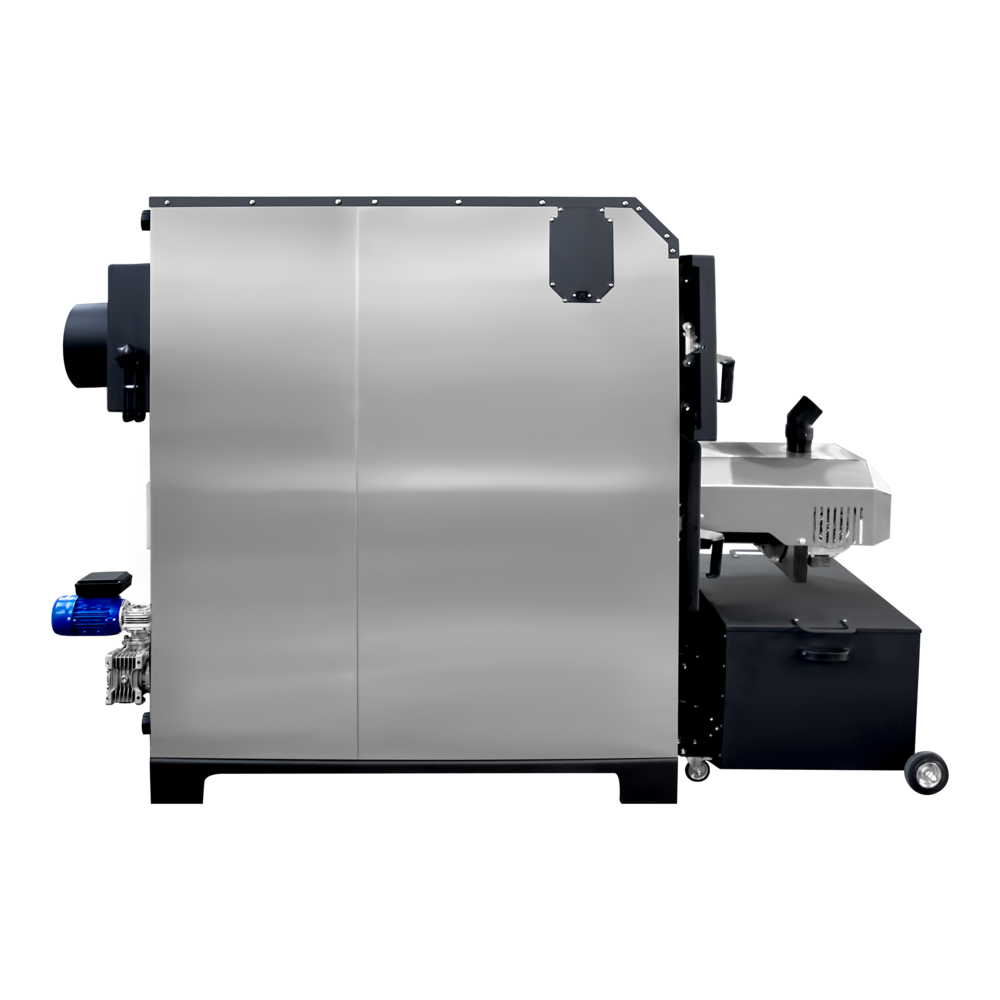

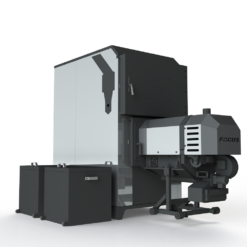

Automated pellet boiler 80 kW FOCUS with built-in industrial pellet burner for households and industries

The FOCUS 80 kW automated pellet boiler with an industrial flare pellet burner and a built-in screw ash removal system into a roll-away container is designed for uninterrupted operation in conditions of high heat removal. The main focus during development was on the efficiency of heat removal, especially when working with high-ash agropellets. This solution is aimed at cost-effectiveness and reducing labor costs associated with cleaning the boiler from ash and plaque. The built-in ash removal system increases the periods between cleanings, which is especially important at facilities with a long heat generation cycle, such as greenhouses, production facilities and remote facilities.

Pellet boiler 80 kW FOCUS and its advantages:

- Maximum ash pan for operation with high-ash fuel. The boiler is specially designed to work with agropellets, which contain more ash than wood pellets.

- Built-in screw ash removal system. Ash from the boiler ash pan is automatically transferred to a roll-away container, which reduces manual cleaning work and increases the periods between maintenance.

- Cleaning the pellet burner. Ash from the burner also enters the boiler ash pan, from where it is removed through a system of screws into an external container.

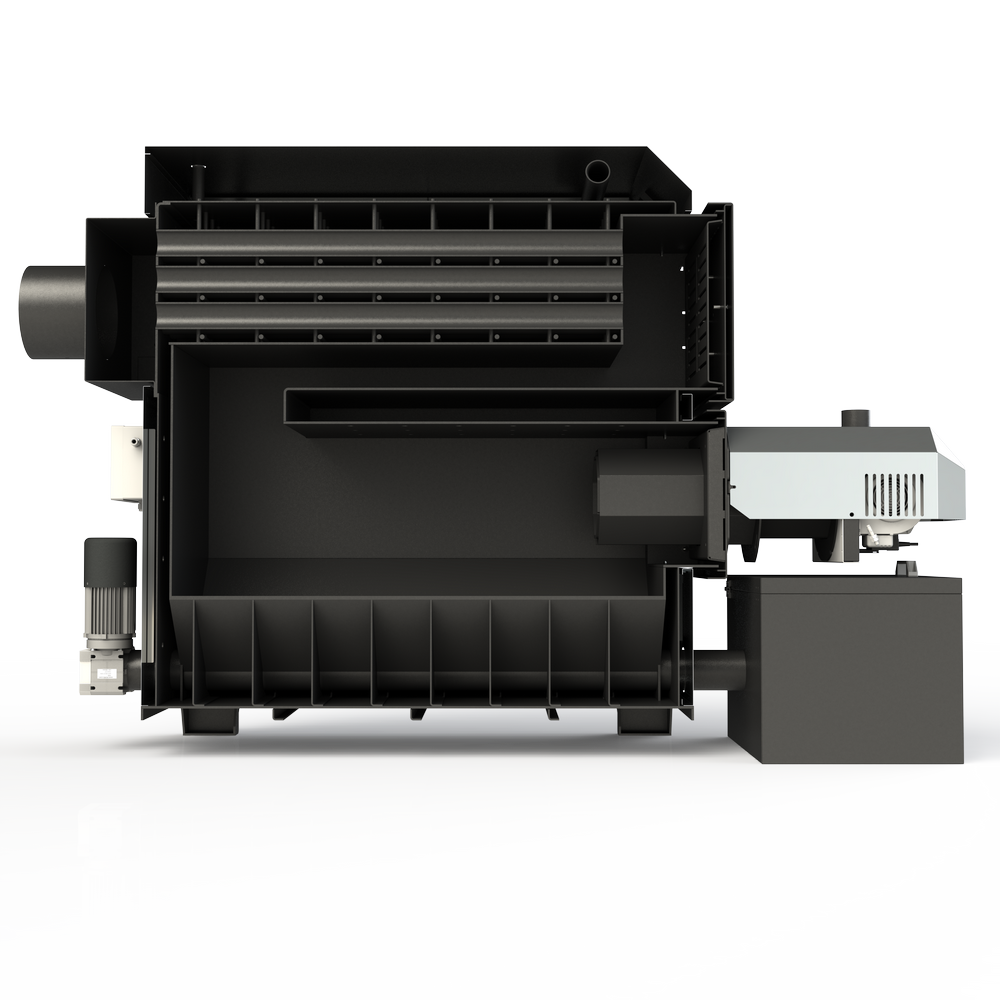

- Hybrid heat exchanger structure. The unique design of the heat exchanger takes into account the infrared radiation of the torch, which reduces thermal stress at the point of impact of the torch, increasing the service life of the heat exchanger. At the same time, heavy particles of volatile substances are deposited, acting as an ash filter.

- The convective part of the heat exchanger is maximally developed. The horizontal heat exchanger increases the efficiency of heat removal, and its design makes maintenance and cleaning easier.

- Ash pan with increased capacity. Designed for operation in industrial conditions, which allows for longer periods without cleaning even with high-ash agropellets.

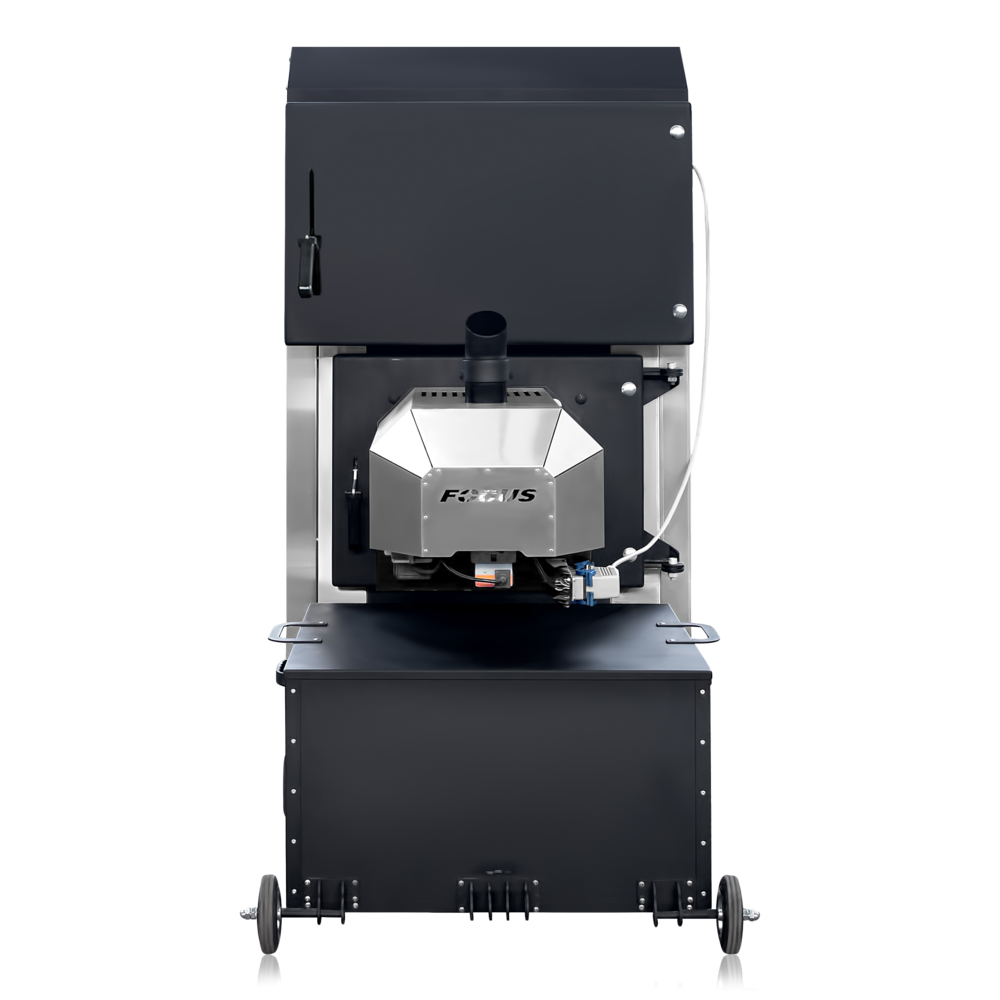

- Suspended burner installation. The burner is located on the boiler door, which facilitates maintenance and repair. Reinforced door hinges increase its reliability.

- Protection against condensation and cold return. At the customer's request, the boiler can be additionally equipped with a three-way or four-way valve with IMP Pumps, which prevents cold return from the heating system from entering the boiler. This protection increases the efficiency by 30% compared to similar boilers without return protection.

- Victaulic quick installation system. The 80 kW FOCUS pellet boiler is equipped with a quick connection system for pipelines without the need for symmetrical tightening and welding at the installation site, which speeds up the installation process and ensures a reliable connection even with small deviations.

- Cascade connection of boilers. The boilers can be connected in a cascade to increase the total capacity of the heating system to 2.2-2.5 MW. In this case, the presence of three-way valves and a hydraulic arrow allows you to turn off an inoperative boiler without disrupting the operation of the system.

- Reliable construction. The boiler is made of structural steel 09G2S with a wall thickness of the heat exchange part of 6 mm and an outer shell of 4 mm, which guarantees durability and resistance to high loads. The outer casing is made of stainless steel AISI201.

- Effective thermal insulation. Basalt mineral wool 50 mm thick provides high-quality thermal insulation and reduces heat loss.

- Flexibility in service. Adjustable door hinges and locks allow for precise door fit, while the large door allows easy access to the heat exchanger for thorough cleaning.

- Hybrid heat exchanger. It consists of a plate and a fire-tube part. The plate stroke relieves the torch tension and precipitates heavy particles, which is especially important when working with agropellets.

- High convective efficiency. The fire-tube part of the heat exchanger ensures maximum heat removal, which makes the system as efficient as possible.

- Convenient cleaning. The 80 kW FOCUS pellet boiler is equipped with a large door, which simplifies access for cleaning and servicing all surfaces of the heat exchanger.

Advantages of a built-in pellet burner:

- Automatic ignition. The burner is equipped with Japanese ceramic candles for contactless air ignition of pellets.

- Movable mono-grid. Used to stir burning fuel and push ash into the boiler ash pan, which improves combustion efficiency and reduces the need for frequent cleaning.

- Fuel feed auger. The 80 kW FOCUS pellet boiler provides a stable supply of pellets into the combustion chamber, which allows maintaining a constant combustion level.

- Auger temperature sensor. Automatically shuts off the fuel supply when the auger overheats, ensuring safe operation.

- Flame sensor. The infrared sensor monitors the presence of flame, regulating the operation of the system depending on the radiation level.

- Efficient combustion. Correctly selected proportions of primary and secondary air provide optimal conditions for complete combustion of fuel, which minimizes emissions and increases the efficiency of the system.

- Reliable drives. The Swiss Belimo drive with anti-jam protection moves the grate plate, ensuring smooth operation of the system.

- Blowing out the combustion chamber nozzle. At capacities from 120 to 150 kW, the nozzle is cooled by air blowing, which improves combustion and increases the durability of the burner.

- Chrome nozzle. All burner models with a capacity from 17 to 150 kW are equipped with nozzles made of chromium alloy, which increases their wear resistance.

Areas of use:

The 80 kW FOCUS pellet boiler is the optimal solution for heating households, small shops, greenhouses and remote facilities that require stable heat with minimal intervention in the operation process. The burner in the kit can operate on clean wood pellets and agropellets with an ash content of up to 10%, which allows the use of more economical types of fuel without damage to the system.

The 80 kW FOCUS pellet boiler and burner are compatible with fuel pellets from sunflower waste, corn, buckwheat, rice, furniture waste and straw, which makes the system universal for various types of fuel.

Functions and equipment

Functionality of the pellet boiler 80 kW FOCUS (15-90 kW):

- power adjustment within 15 kW – 90 kW;

- 5 levels of security;

- automatic operation: ignition, extinguishing, weather regulation, critical events, ash cleaning;

- ash removal by a screw system into an external ash collector automatically;

- automatic cleaning of the burner into the common ash collector;

- ceramic spark plug, duplication of spark plugs;

- low power consumption (800 W);

- PID control for device control and smart home;

- movable mono-grate (removable) made of chromium alloy for mechanical cleaning of the burner;

- pump control (DHW and heating);

- working with thermostats and internet module;

- work with weather regulation;

- Built-in ash filter in the form of a plate heat exchanger.

Pellet boiler 80 kW FOCUS complies with GOST32452-2013 (EN 15270:2007). 12-month warranty.

Contents of delivery:

- pellet boiler 80 kW FOCUS complete with burner, screw ash removal system;

- sliding ash collection container - kit;

- EcoNet internet module;

- weather sensor;

- smoke gas temperature sensor;

- boiler return temperature sensor;

- feeding screw conveyor - 2 m;

- corrugated PVC pipe - 1 m;

- pellet burner controller;

- documentation.

Equipment for pellet boiler rooms

Devices and modules that increase the level of autonomy of the heating system:

- piping kits with a three-way or four-way valve integrated into the boiler control system;

- bins for storage and feeding of pellets;

- room touch EcoSter regulator;

- additional temperature sensors.

Consult our specialists on the specifics of deploying heating circuits and connections. The automated pellet boiler 80 kW FOCUS allows you to deploy a full-fledged smart heating system on any scale.

Dimensions (edit)

Listed in each position separately.

Chimney diameter

220 mm

Requirements for the boiler room

When designing, you must adhere to the requirements:

- MDNAOP 0.001.26-96;

- DBN B.2.5-XX: 20XX;

- SNiP 2.04.05-91 "Heating, ventilation and air conditioning";

- SNiP II-35-76 "Boiler plants".

Interesting to read

Pellet burner operation process in detail

Which solid fuel boiler to buy for production

Reviews

There are no reviews yet.