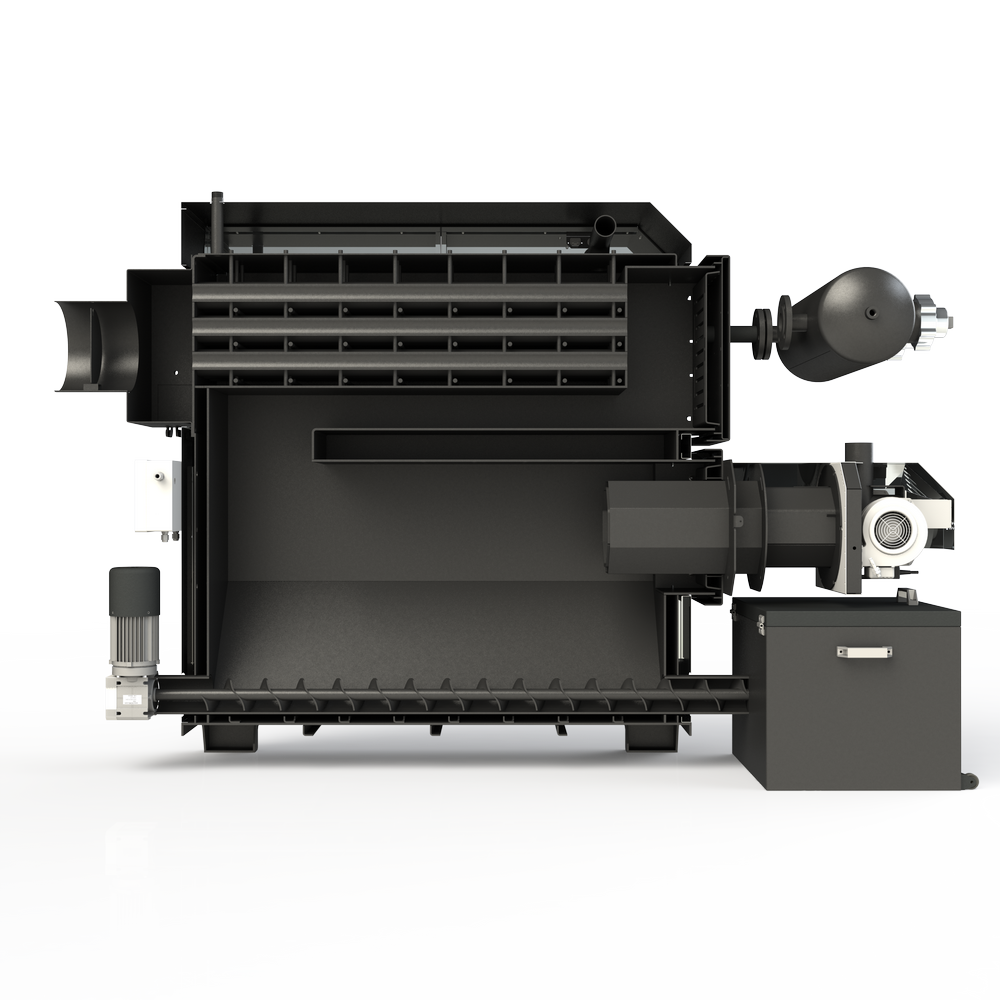

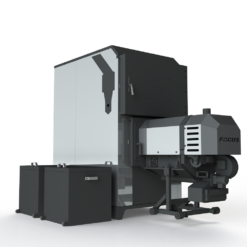

Pellet boiler 50 kW FOCUS: fully automated solution with ash removal and pneumatic cleaning system

The 50 kW FOCUS pellet boiler is a complete automated heating solution, equipped with a built-in industrial pellet burner, a screw ash removal system and pneumatic heat exchanger cleaning. The boiler is designed to operate in conditions of high ash content of fuel and is designed in such a way as to minimize manual maintenance.

Key Features:

- Screw ash removal: Automatic ash removal via a screw system into a roll-away container significantly reduces the need for manual cleaning.

- Pneumatic cleaning of heat exchanger: Compressed air supplied through a system of nozzles with a receiver ensures regular cleaning of the heat exchanger from ash and scale, which increases the efficiency of the boiler and maintains its stable operation.

- Automatic operation: The 50 kW FOCUS pellet boiler is equipped with automation that controls the ignition, fuel supply, cleaning and temperature maintenance processes. It also provides functions for controlling the heat exchanger pneumatic cleaning cycles.

- Hybrid heat exchanger: The combination of plate and fire-tube heat exchanger design allows to effectively cope with thermal loads and retain heavy ash particles, improving the operation of the agro-pellet boiler.

- Maximum ash pan: The 50 kW FOCUS pellet boiler is equipped with an enlarged ash pan, which is especially important when using agropellets with a high ash content (up to 10%).

Advantages of the automated system:

- Efficiency of working with high-ash pellets: Specially designed design ensures smooth operation even when using agro pellets, making this boiler cost-effective for use in agriculture and other sectors.

- Screw ash removal system: The system automatically removes ash from the grate space into the boiler ash pan, from where it is then moved to a roll-away container for subsequent disposal.

- Compact installation: Thanks to the Victaulic quick-connection system, installation of the boiler is quick and easy, without the need for complex installation work.

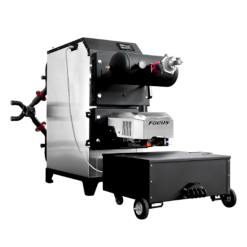

Pellet burner FOCUS

The burner installed on this boiler supports operation on both wood and agro pellets with an ash content of up to 10%. Ceramic spark plugs, flame sensors and temperature controllers ensure safe and efficient operation of the system.

Additional options:

- Possibility of installing three-way valves and pumps to protect against cold return, which increases the efficiency of the system to 30%.

- The boiler can be supplemented with a cascade system to increase the capacity to 2.2–2.5 MW, making it an ideal choice for large facilities and industrial enterprises.

Technical specifications:

- Power: 6–55 kW, adjustable

- Fuel: Wood and agropellets (sunflower, corn, buckwheat, straw)

- Materials: Steel 09G2S, heat exchanger 6 mm, water jacket 4 mm, casing made of stainless steel AISI201

- Insulation: Basalt mineral wool 50 mm thick

This boiler is suitable for both domestic and light commercial applications, offering high performance and minimal maintenance.

Priority functions of the proposed boiler:

- Pellet boiler 50 kW FOCUS with pellet burner.

- Auger ash removal system with a retractable container.

- Pneumatic heat exchanger cleaning system.

- Internet module for remote control.

- A set of sensors (weather, flue gas temperature and return).

The boiler complies with GOST32452-2013 (EN 15270:2007) standards and is provided with a 12-month warranty.

Contents of delivery:

- Pellet boiler 50 kW FOCUS complete with burner, screw ash removal system, pneumatic ash removal system;

- sliding ash collection container - kit;

- EcoNet internet module;

- weather sensor;

- smoke gas temperature sensor;

- boiler return temperature sensor;

- feeding screw conveyor - 2 m;

- corrugated PVC pipe - 1 m;

- pellet burner controller;

- documentation.

Equipment for pellet boiler rooms

Devices and modules that increase the level of autonomy of the heating system:

- harness kits with a three-way or four-way valve integrated into the boiler control system;

- bins for storage and feeding of pellets;

- room touch EcoSter regulator;

- additional temperature sensors.

Consult our specialists on the features of the deployment of heating circuits and connections.

Dimensions (edit)

Listed in each position separately.

Chimney diameter

180 mm

Requirements for the boiler room

When designing a boiler room where you plan to install a 50 kW FOCUS pellet boiler, you must adhere to the following requirements:

- MDNAOP 0.001.26-96;

- DBN B.2.5-XX: 20XX;

- SNiP 2.04.05-91 "Heating, ventilation and air conditioning";

- SNiP II-35-76 "Boiler plants".

Interesting to read

Pellet burner operation process in detail

Which solid fuel boiler to buy for production

Reviews

There are no reviews yet.