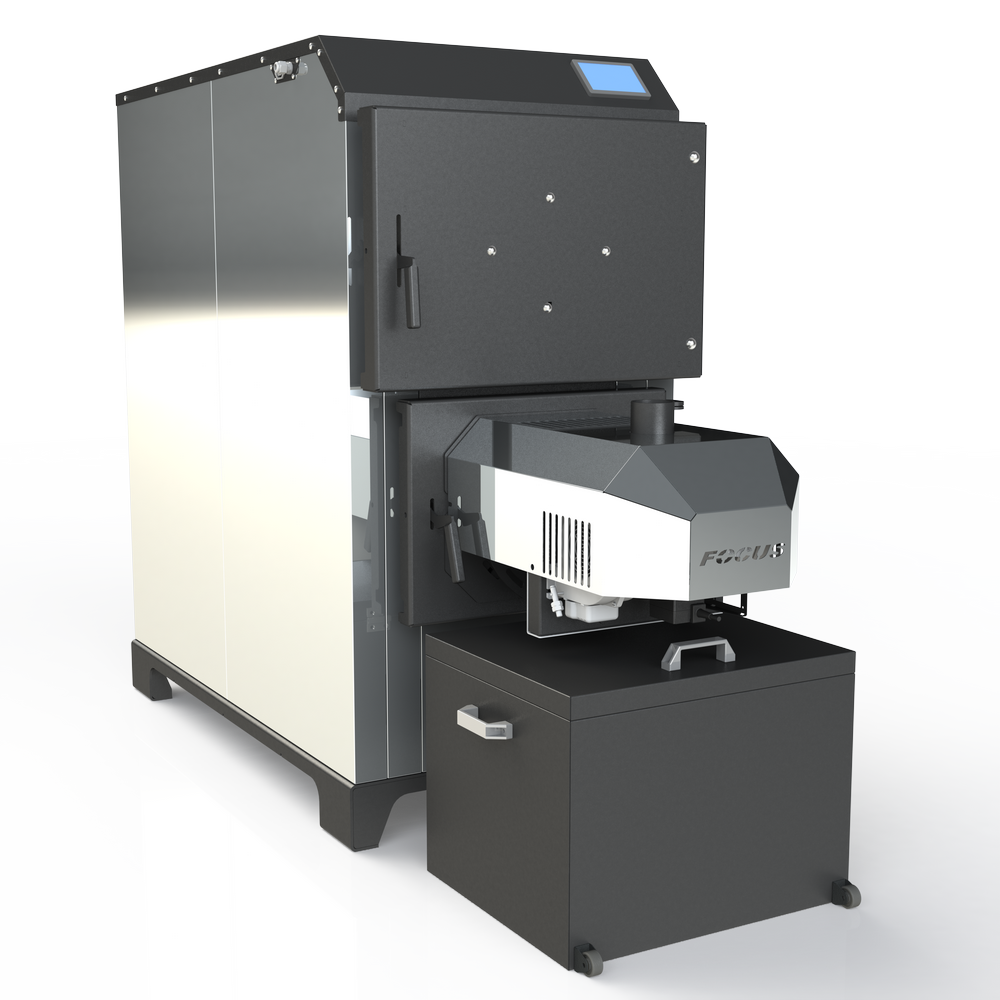

Pellet boiler 150 kW FOCUS for automatic heating of offices, houses, farms and greenhouses

Automated pellet boiler 150 kW FOCUS is designed for efficient heating of industrial facilities and has a number of characteristics and advantages:

Main characteristics:

- Power: 150 kW.

- Burner type: Built-in industrial pellet burner, operating on both pure wood pellets and agro pellets with ash content up to 10%.

- Ash removal system: Built-in auger ash removal system with a roll-away container for easy ash removal.

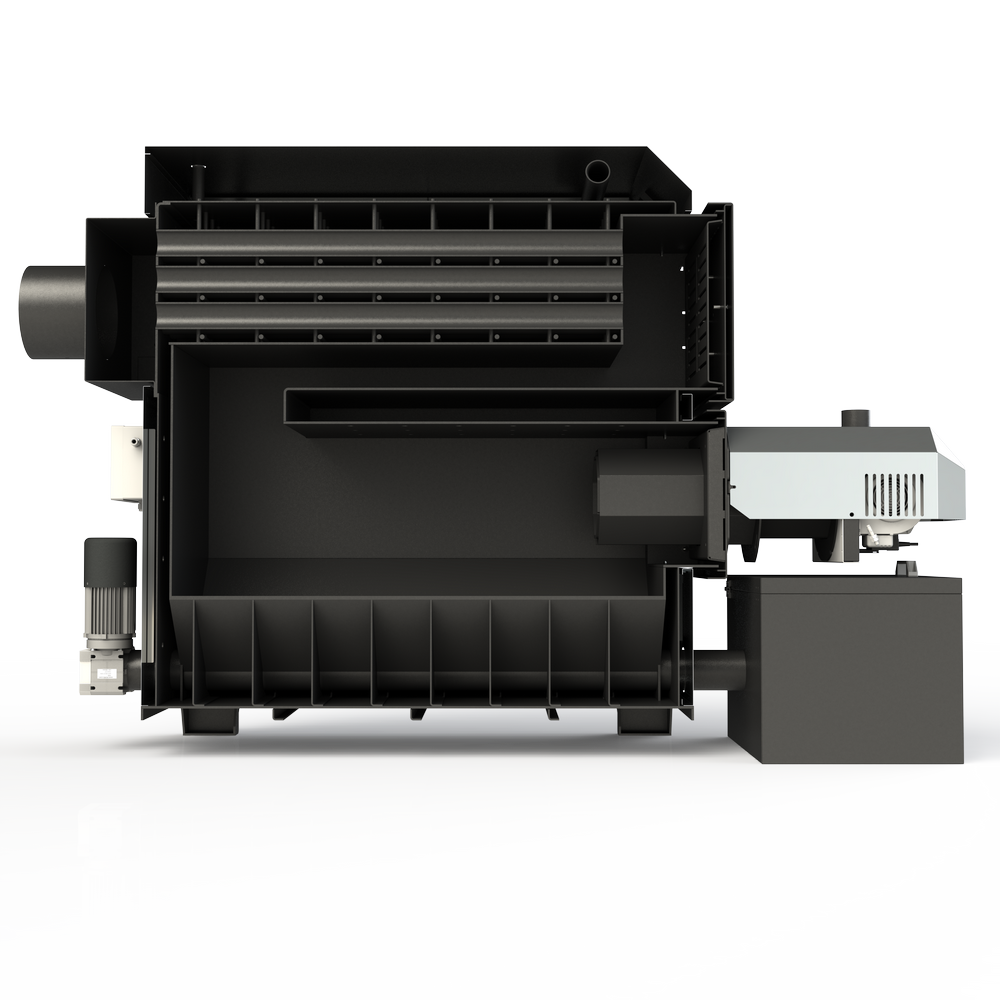

- Heat exchanger structure: Hybrid, including a horizontal heat exchanger and a combustion chamber.

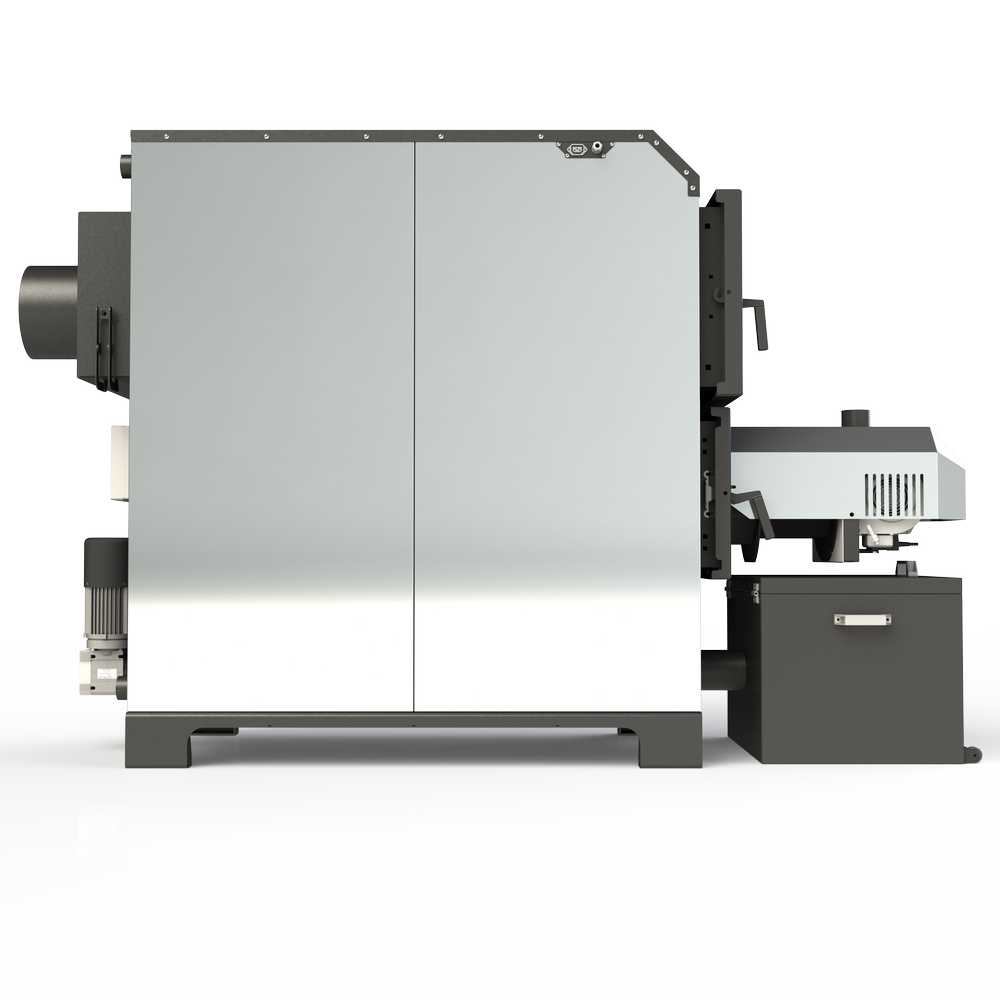

- Boiler material: Structural steel 09G2S with a wall thickness of the heat exchange part of 6 mm and an outer shell of 4 mm.

- thermal insulation: Basalt mineral wool 50 mm thick.

- Casing: Stainless steel AISI201 ground.

Advantages:

- Maximum ash pan: Specially designed to work with high ash fuel, increasing heating efficiency.

- Long intervals between cleanings: The screw ash removal system allows to significantly reduce the frequency of boiler maintenance.

- Hybrid heat exchanger: Combines plate and fire tube heat exchangers, which ensures effective removal of thermal stress.

- Ease of maintenance: Wide hatch for easy access to the heat exchanger and ash chamber in front of the chimney.

- Quick installation system: Equipped with Victaulic quick coupling system for easy installation and no welding required.

- Cascade connection: Possibility of creating a cascade connection system, which allows you to painlessly add boilers to increase capacity.

- Adjustable hinges and locks: Ensure precise adjustment and tight fit of the ash pan door and heat exchanger to the opening.

- Safety: Built-in auger and flame temperature sensors, as well as automatic ignition to prevent accidents.

Additional functions:

- Movable mono-grid: Used for stirring fuel and removing high-ash residue into the ash pan.

- Adjustable air proportions: Ensure optimal combustion of pellets.

- Air blow nozzle: Increases efficiency by cooling the nozzle and heating the secondary air.

- Automatic burner cleaning: Integrated into the overall boiler ash removal system.

Application:

The 150 kW FOCUS pellet boiler is the optimal solution for households, small shops and remote sites where a stable heat supply and time savings on maintenance are required.

Functions and equipment

Functionality of pellet boiler 150 kW FOCUS (20-150 kW):

- power range 20 kW – 150 kW;

- 5 levels of security system;

- fully automatic: ignition, extinguishing, automatic ash cleaning during operation, cleaning of the main ash during extinguishing;

- screw ash removal into the ash receiver in automatic mode;

- automatic cleaning of the burner into the ash collector;

- ceramic spark plug, spare spark plug duplicate;

- power consumption (800 W);

- PID control (for smart home applications and other solutions);

- removable mono-grate, movable, made of chromium alloy for mechanical cleaning of the burner;

- control of pumping groups (hot water treatment and heating);

- working with thermostat and internet module;

- switching on and off depending on the outside air temperature;

- built-in ash filter in the form of a plate heat exchanger.

The pellet boiler is manufactured in accordance with GOST32452-2013 (EN 15270:2007). 12-month warranty.

Contents of delivery:

- pellet boiler 150 kW FOCUS complete with burner, screw ash removal system;

- sliding ash collection container - kit;

- EcoNet internet module;

- weather sensor;

- smoke gas temperature sensor;

- boiler return temperature sensor;

- feeding screw conveyor - 2 m;

- corrugated PVC pipe - 1 m;

- pellet burner controller;

- documentation.

Equipment for pellet boiler rooms

Devices and modules that increase the level of autonomy of the heating system:

- harness kits with a three-way or four-way valve integrated into the boiler control system;

- bins for storage and feeding of pellets;

- room touch EcoSter regulator;

- additional temperature sensors.

Consult our specialists on the specifics of installing heating and boiler circuits.

Dimensions (edit)

Listed in each position separately.

Chimney diameter

250 mm

Requirements for the boiler room

When designing, you must adhere to the requirements:

- MDNAOP 0.001.26-96;

- DBN B.2.5-XX: 20XX;

- SNiP 2.04.05-91 "Heating, ventilation and air conditioning";

- SNiP II-35-76 "Boiler plants".

Interesting to read

Pellet burner operation process in detail

Which solid fuel boiler to buy for production

Reviews

There are no reviews yet.