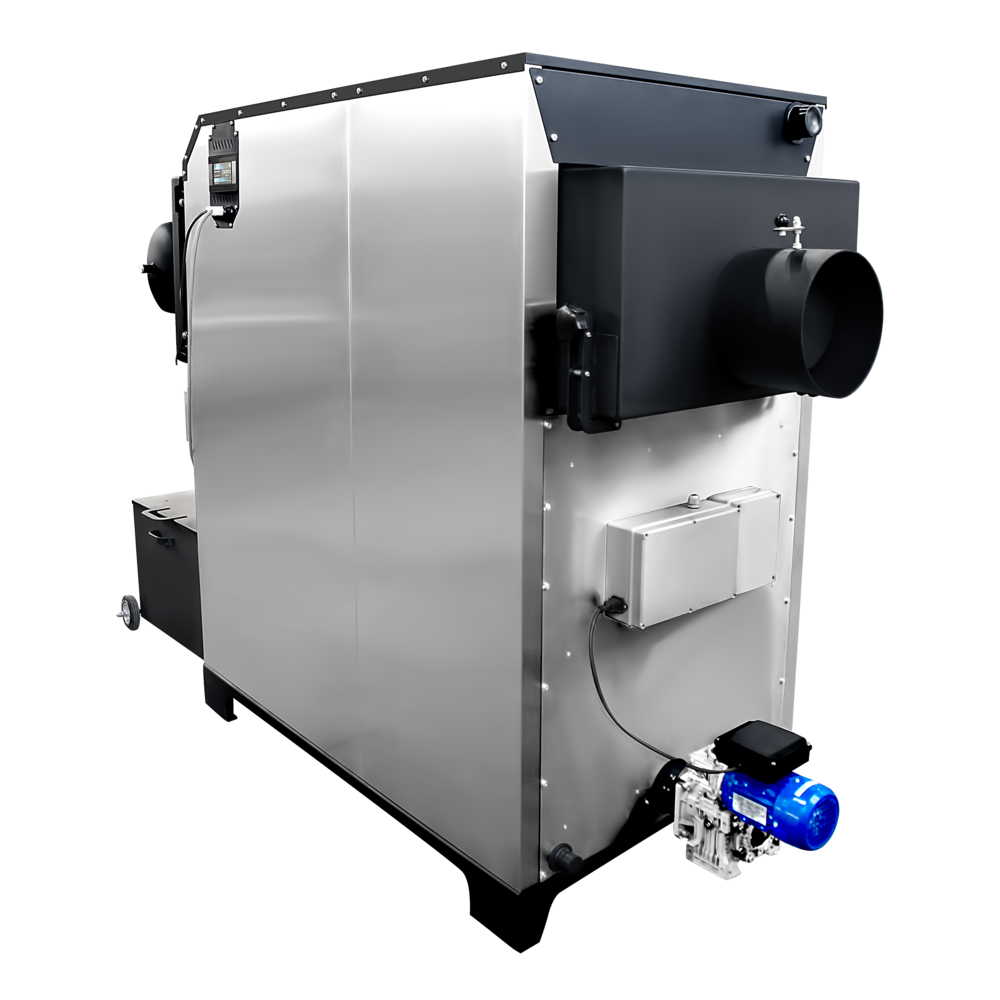

Pellet boiler 80 kW FOCUS: the optimal solution for autonomous heating

Automated pellet boiler 80 kW FOCUS, power range (15-90 kW) — is innovative and highly efficient equipment, specially created for facilities requiring stable and reliable heat supply. Equipped with advanced automation systems, this boiler is distinguished by the ability to work with various types of fuel, including agropellets, which makes it especially relevant for agricultural facilities, greenhouses and private homes.

Advantages of a pellet burner

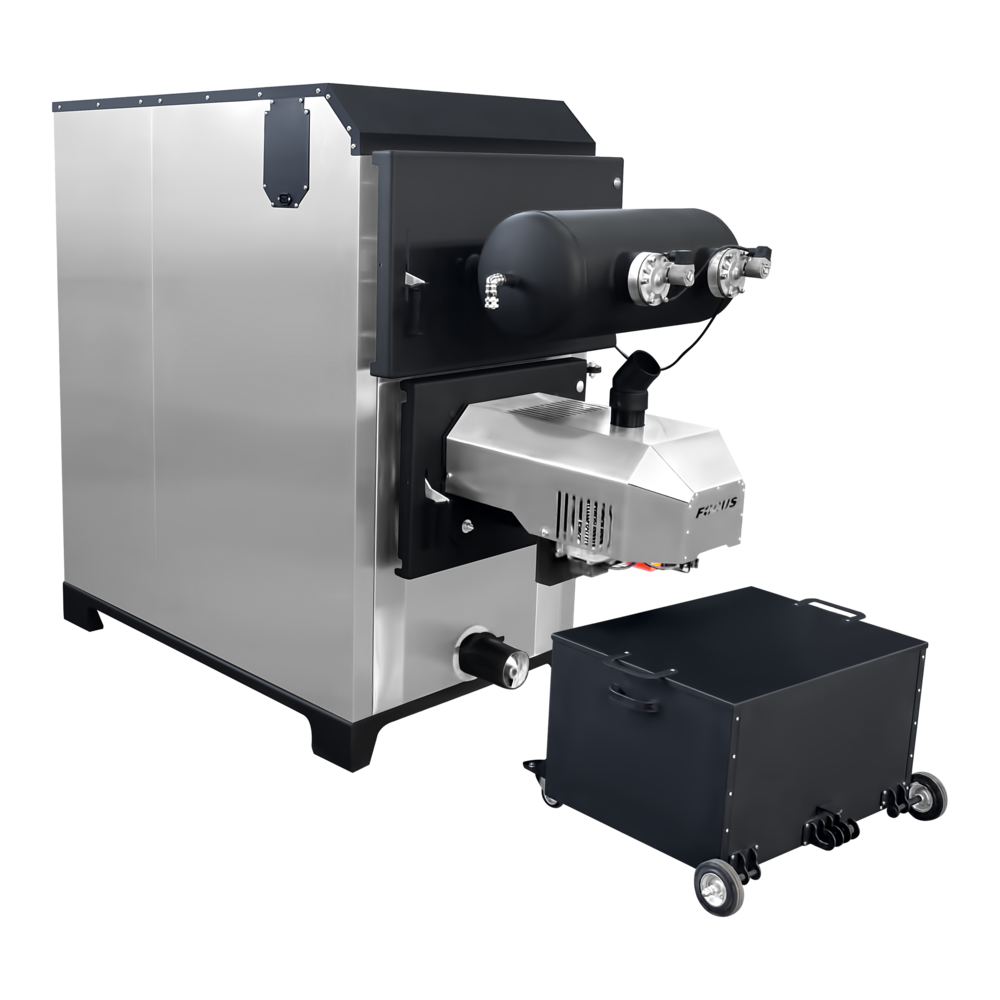

The key element of the boiler is Automatic pellet burner, designed to operate with high ash pellets, including wood and agripellets with ash content up to 10%. This allows the use of more affordable fuels, such as pellets from agricultural waste.

The main advantages of the burner:

- Automatic ignition with the use of Japanese ceramic candles ensures a quick and safe start of work.

- Movable mono-grid effectively cleans fuel from ash, reducing the risk of its accumulation.

- Integrated security systems, such as infrared flame sensor and auger temperature control, ensure reliable operation.

- The advanced air supply system ensures optimal combustion and high boiler efficiency.

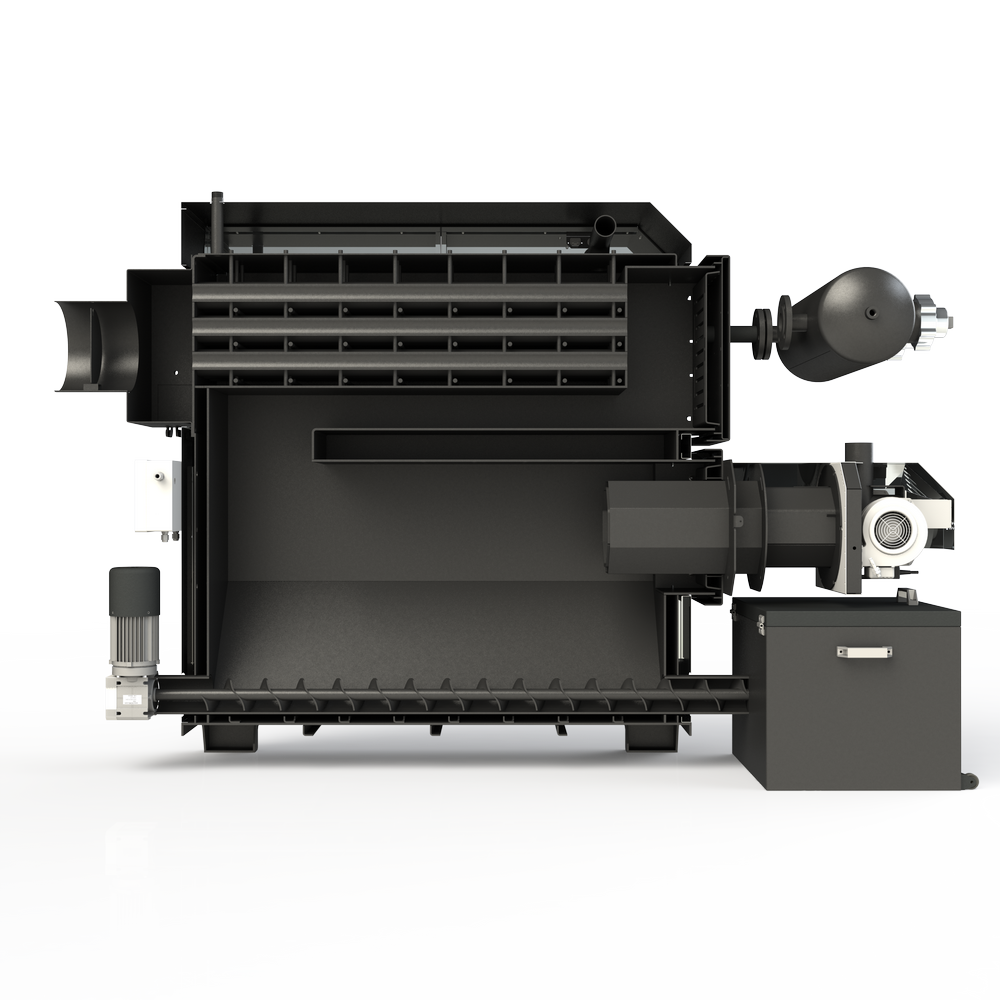

Innovative heat exchanger: hybrid design for maximum efficiency

The 80 kW FOCUS pellet boiler is equipped with a unique hybrid heat exchanger, specially adapted for use with a flare burner. The design is based on an advanced ash deposition and heat transfer system.

Heat exchanger features:

- Plate heat exchanger Reduces thermal stress from the torch and simultaneously captures heavy ash particles, preventing them from entering the chimney.

- Horizontal convective part ensures maximum thermal efficiency, and the large ash chamber significantly increases the intervals between cleanings.

- Ease of access to the heat exchanger through a wide hatch simplifies the maintenance process.

Automation to reduce labor costs

One of the key features of the boiler is its full automation, which allows to minimize manual intervention in the work process.

- Screw ash removal system provides automatic removal of ash from the ash pan into a roll-away container, which significantly reduces the time required for boiler maintenance.

- Pneumatic heat exchanger cleaning system prevents ash accumulation on its surfaces, ensuring stable operation of the boiler and maintaining a high level of efficiency.

- Automation system regulates not only the boiler power (from 10 to 65 kW), but also the ignition, extinguishing and pneumatic cleaning processes. Additionally, integration with smart home systems is possible.

Comprehensive protection and extension of equipment service life

To increase the durability and safety of the boiler, the 80 kW FOCUS pellet boiler is equipped with a cold return and condensation protection system. Thanks to the use of three-way or four-way valves, the boiler is protected from unwanted temperature changes, which increases its service life and improves efficiency.

The 80 kW FOCUS pellet boiler can also be installed in a cascade system, which allows for a significant expansion of the total heat supply capacity of facilities up to 2.5 MW. This makes the 80 kW FOCUS pellet boiler a flexible and cost-effective solution for large production complexes.

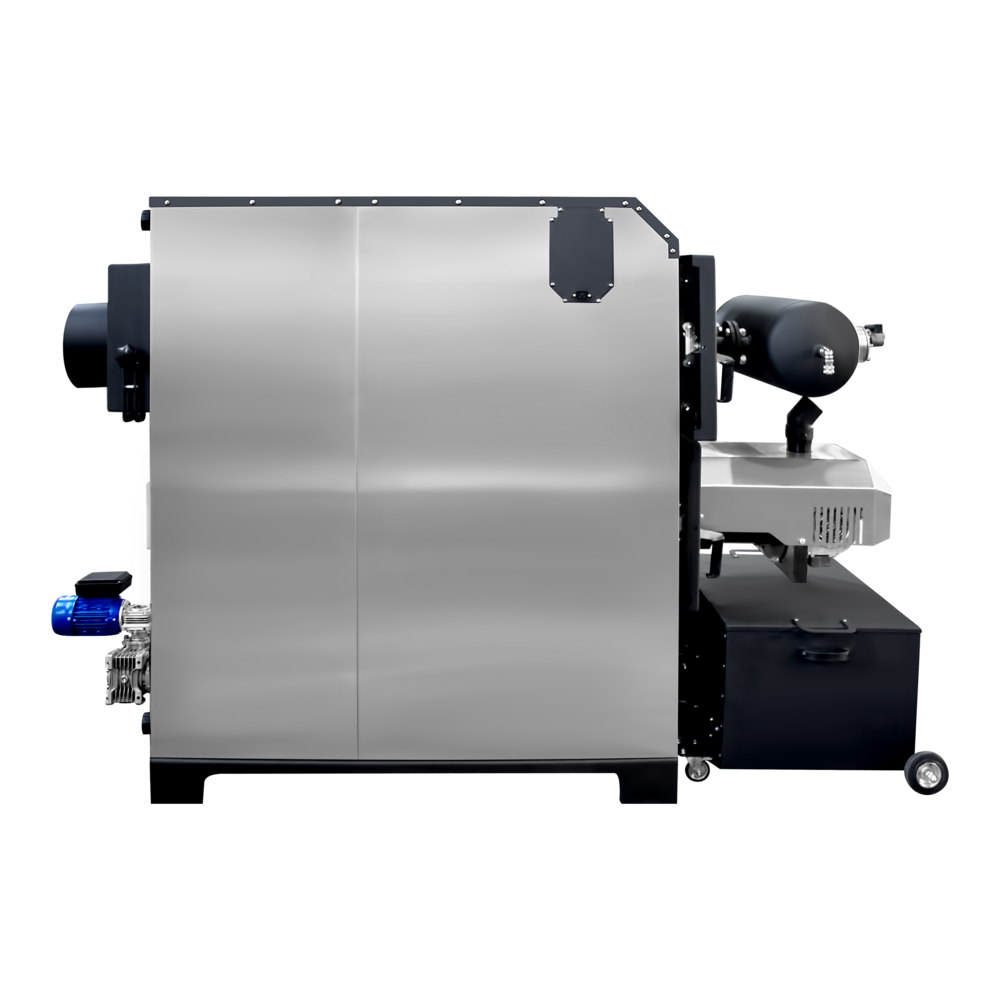

Robust construction and reliable materials

Boiler body made of high-quality structural steel 09G2S with a wall thickness of 6 mm, which guarantees durability even under constant high loads. The outer shell is equipped with thermal insulation made of basalt mineral wool, and the outer casing is made of stainless steel AISI201, which gives the boiler additional resistance to corrosion and external influences.

All door elements are equipped with adjustable hinges and locks, which allows for easy adjustment and maintenance of the boiler, and also ensures a tight fit of the doors to prevent heat leakage.

Increased security and integration with modern standards

The safety of the boiler is guaranteed by the presence of all necessary sensors and protection systems, including:

- Infrared flame sensors for monitoring the combustion process.

- Temperature sensors on the fuel supply auger to prevent emergency situations.

The 80 kW FOCUS pellet boiler complies with all international safety and quality standards, including GOST 32452-2013 (EN 15270:2007), and comes with a 12-month warranty.

The 80 kW FOCUS pellet boiler is a versatile, reliable and cost-effective solution for heating both industrial and private facilities. Its main advantages are a high level of automation, the ability to work with agropellets and a reliable design, which makes it an ideal choice for those looking for efficient and low-cost heat supply.

Functions and equipment

Functionality of the pellet boiler 80 kW FOCUS (15-90 kW):

- fine power regulation in the range of 15 kW – 90 kW;

- 5 levels of security;

- automatic operation: ignition/extinguishing, ash removal, ash cleaning during extinguishing;

- automatic auger ash removal into a retractable ash collector;

- cleaning the pellet burner in the boiler ash removal container;

- ceramic spark plug, spare spark plugs;

- power consumption - 800 W;

- PID control for control and smart home;

- movable (removable) mono-grate made of chromium alloy for mechanical cleaning of the burner;

- control of heating circuits by changing the pump speed (DHW, heating, three- and four-way valves);

- work with heating control devices and an Internet module; interaction with a weather controller, switching on when the air temperature drops;

- built-in ash filter in the heat exchange complex.

Contents of delivery:

- pellet boiler 80 kW FOCUS complete with burner, screw ash removal system, pneumatic ash removal system;

- sliding ash collection container - kit;

- EcoNet internet module;

- weather sensor;

- smoke gas temperature sensor;

- boiler return temperature sensor;

- feeding screw conveyor - 2 m;

- corrugated PVC pipe - 1 m;

- pellet burner controller;

- documentation.

Equipment for pellet boiler rooms

Devices and modules that increase the level of autonomy of the heating system:

- harness kits with a three-way or four-way valve integrated into the boiler control system;

- bins for storage and feeding of pellets;

- room touch EcoSter regulator;

- additional temperature sensors.

Consult our specialists on the specifics of deploying heating circuits and connecting the boiler. The boiler room where the 80 kW FOCUS pellet boiler will be installed will provide maximum comfort thanks to zonal heating.

Requirements for the boiler room

When designing, you must adhere to the requirements:

- MDNAOP 0.001.26-96;

- DBN B.2.5-XX: 20XX;

- SNiP 2.04.05-91 "Heating, ventilation and air conditioning";

- SNiP II-35-76 "Boiler plants".

Interesting to read

Pellet burner operation process in detail

Which solid fuel boiler to buy for production

Reviews

There are no reviews yet.