How it is installed in the boiler pellet burner with automatic feeding?

The pellet flare burner with automatic feeding does not require any structural changes when installed in the boiler. The module is a fully functional version of the heater with a refractory combustion chamber, ignition and pellet conveyor. On sale offered pellet burners FOCUS power from 17 before 900 kWt... The installation principle is the same. The pellet burner, when installed, becomes the main heating module with firmware functions.

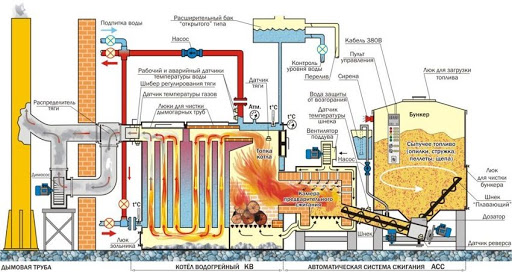

Installation principle pellet burner with automatic feeding

The heating device is designed to modernize a solid fuel boiler with minimal installation requirements. The burner is traditionally installed in the combustion chamber door. To preserve the function of the boiler firing with different fuels, it is better to purchase a model with two doors. The manufacturer provides the adjustment of the pellet burner. The models do not require maintenance. Many burners, except for the younger ones, have a cleaning system. Manufacturers supply more powerful industrial versions with water cooling.

Any pellet burner, regardless of type, is supplied with a feeder. V pellet boilers at the moment, gravitational and auger forced fuel supply is used. The second option allows you to automate and dose the fuel supply in accordance with the requirements for the intensity of combustion. Usually forced feeding is a concomitant design solution to a flare burner that maintains a heat capacity bulk combustion.

Recommendations for the purchase of a household boiler for a fuel burner to switch to granular fuel

If you have a boiler room connected to heating circuits and a solid fuel boiler, you only need buy pellet burner and a storage bin for pellets.

Due to the peculiarities of installation, when selecting the technical parameters of the pellet module for the boiler, the following recommendations can be made:

- solid fuel boiler must have a comparable power to the burner, but the pellet burner can be more powerful;

- you should pay attention to the boiler heat exchanger and give preference to a model with a larger heat exchange surface;

- in case of independent boiler manufacture, several circuits can be used as a heat exchanger, including pyrolysis afterburning of fuel and secondary heat exchange with combustion products. In this case, a tube jacket is made to prepare hot air for air heating.

Please note that when installing a pellet burner, the boiler is a structural "jacket" with heat exchange functions. All other possibilities are realized by a pellet burner with automatic feed FOCUS and with microprogram PLUM management.