Does multi-circuit heating in production allow you to optimize costs?

Heating of industrial premises is a current engineering topic, more related to heating engineering and the optimal choice of equipment. Today we will discuss how effective it is to deploy multi-circuit heating in production with climate control and multiple functions, and how it can be made cheaper. Reducing the cost of installing heating systems is important for both large and small businesses. For this reason, we decided to analyze this topic by using the new FIREBOX FOCUS monoblock boiler model for heating.

Multi-circuit heating in production

Several heating circuits are usually used in private real estate to combine different technologies for heating a room from one boiler. Heating of other facilities, including industrial ones, is often built using the same principle. But how effective this is requires analysis.

The main contradiction in the use of heating from a centralized boiler house in production is due to the fact that during heat transportation there are still large heat losses. It’s one thing when it comes to steam heating, and there is simply no way to supply heat to individual circuits; they are united by a common system. It’s another matter when space heating can be organized locally, but without heat loss during transportation from a common boiler room.

Even in private homes, they are currently trying not only to highlight the heating circuits. For example, floor by floor, but also simply connecting different heat sources as needed. In other words, multi-circuit heating in production is advisable only when it is necessary to combine heating methods and supply heat from one boiler.

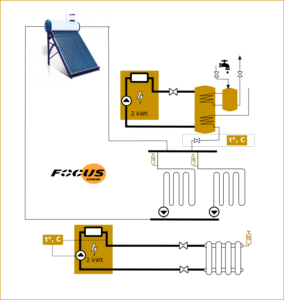

How is multi-circuit heating implemented in production using the FOCUS monoblock pellet boiler?

In modern industries, three types of heating are usually used:

- air heating;

- low-temperature heated floors in unheated rooms to maintain a comfortable temperature;

- heating radiators, including for heating workplaces.

These technologies are not flawless, but they make it possible to maintain the required temperature levels in the workshops. Especially when there is a multi-circuit system.

If such an implementation is required, multi-circuit heat supply can be provided for a small workshop from one FOCUS monoblock pellet boiler.

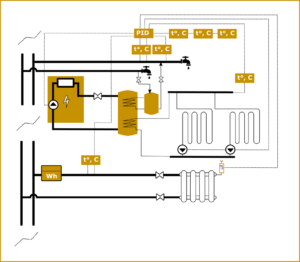

It is recommended to implement this in the following way:

- warm floors for spring and autumn heating;

- high-temperature radiators for heating the workshop in winter;

- air heating for workplaces.

FOCUS monoblock allows you to connect a multi-circuit heating system via a DHW circuit, an indirect heating boiler or a heat accumulator. Or you can use another heating option by physically switching the circuits using a bypass from high-temperature radiators to warm floors or air heating.

Mechanical switching of circuit operating modes with appropriate setting of the boiler operating mode has its advantages. First of all, they are associated with the ease of implementation of such a system and the high efficiency of automatic heating from a pellet boiler with a flare burner, which ensures high efficiency of fuel combustion. \

Multi-circuit heating in production is still not effective if you use the modular principle of heat supply. But you can switch heating circuits using a bypass to use multiple heating technologies for your convenience.