Automated heating and its features with examples

Any automated equipment has its own characteristics, this also applies to heating. It should be immediately noted that automated heating does not mean that all processes in your boiler room are automatic, and the concept of degree of automation is used to characterize them. Today we will look at how to make sufficient automated heating for different objects.

Automated heating: about the features of deploying automated heating

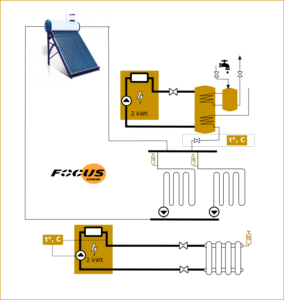

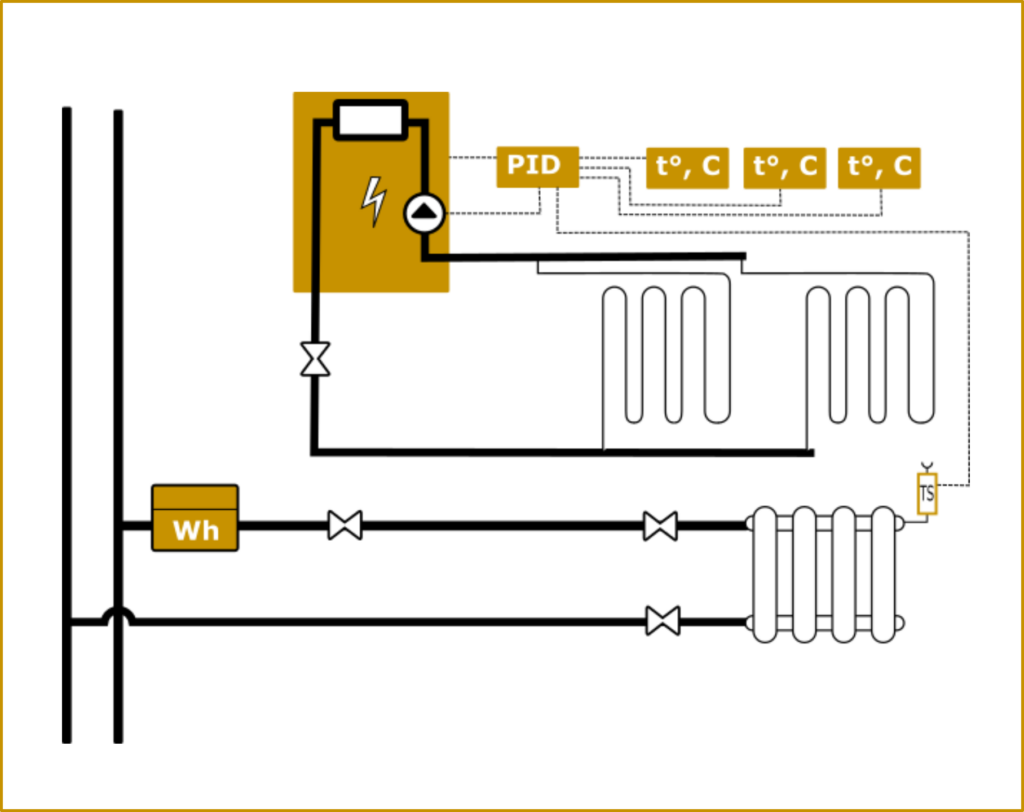

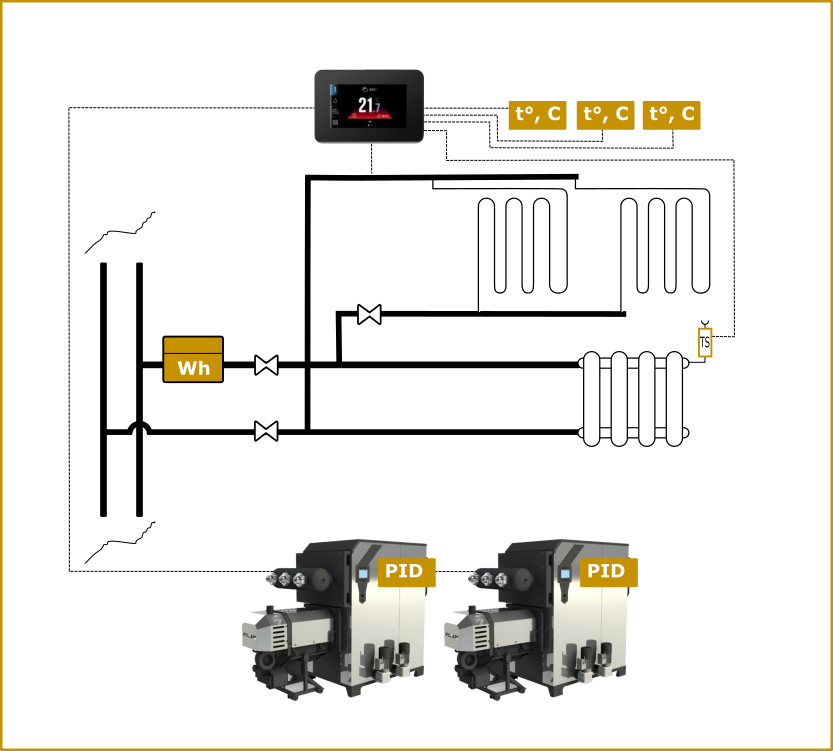

Let’s immediately emphasize that at least two relatively independent heating segments are classically used - this is the heating circuit in which the boilers are located, and the boiler circuit with radiators, heated floors, hot water supply and other equipment. They are separated hydraulic arrow. In this segment, climate control devices are installed, but if they are not available, as is often done in apartment buildings, then the heating circuit with boilers can be, and most often in large facilities, automated. This greatly simplifies operation.

In other words, we can automate heating in segments and individual circuits. At the same time, some boilers already have built-in microcontrollers with fairly broad functionality, which allows you to control the entire heating system at once and adjust heating needs depending on the temperature and the user’s wishes.

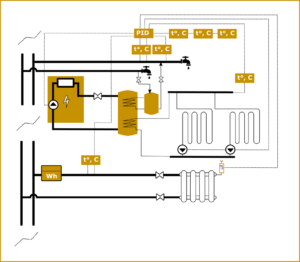

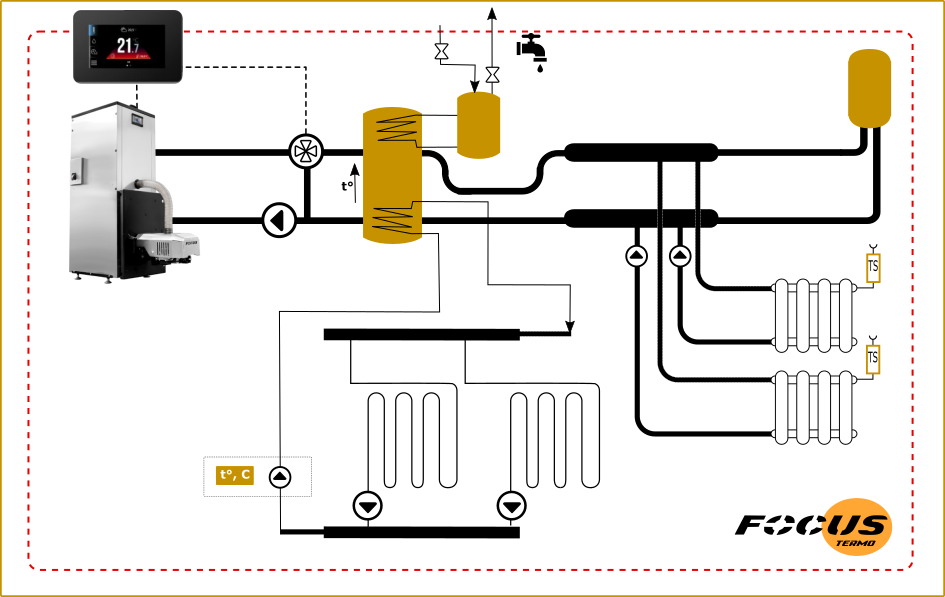

This becomes clearer using the example of the equipment produced by our company. For example, pyrolysis boiler FOCUS controlled by microcontroller EcoMAX260, which is intended for CT equipment with manual loading. The controller controls the air supply to the firebox and three-way valves, which help maintain the same temperature for the hot water supply and the heating circuit.

Climate control in such systems is done using a separate device, for example, EcoMAX 360 and is implemented, as a rule, using a buffer capacity. This is done in order not to lose residual heat if the heating needs are less and the addition of water from the “return” is required.

Wherein pellet monoblock boiler FOCUS, like other models of FOCUS pellet boilers, operate on the basis of a weather regulator EcoMAX860. This device supports advanced features and allows you to manage more climate control hardware support using expansion modules.

In other words, the buyer makes a choice to what extent his boiler room will be automated. Now let's figure out how heating is automated.

The technical side of heating automation

To understand what is needed to automate heating in your apartment or house, you need to understand how it is done. First of all, we note that the question concerns heating with water coolant. For air, electric and steam the approaches are slightly different, but in general the concept of segmental heating remains the same. In other words, in order to control something using a digital device, this equipment must be separated into a segment or organized as a separate circuit. This is how automated heating works and is controlled. Already in the heating circuit, segmentation can be added using thermostats and valves, but this depends on the technology.

In water heating, automated heating control is implemented in two ways:

- using pumps that drive hot coolant at different rates;

- using valves in the existing circuit, that is, a smaller amount of hot coolant can pass through the battery, taking into account the fact that the pump in one heating circuit sets the movement of water at the same speed.

To control this process, so-called pump groups are sold. They may include different amounts of equipment; in the minimum optimal version, this is a safety group, a pump and a coolant temperature sensor. For heated floors, such a pump group must be supplemented with a three-way valve for mixing water from the “return” and maintaining the set temperature. It will be useful in systems with an unregulated TT boiler and a metal-plastic pipeline and modern radiators designed for temperatures up to 90 degrees Celsius. Temperature regulation is very important, otherwise the pipes will simply melt.

Expensive purchases can be avoided by installing a metal heating circuit with 3 cast iron radiators. Since more distant radiators will have a lower temperature. If your heating circuit is cast iron, you can optimally regulate the temperature with a simple pump group in a certain room.

How to equalize the temperature in radiators

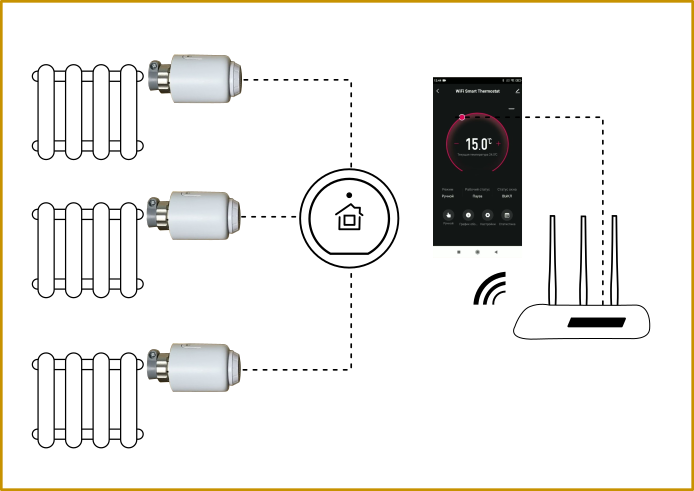

The requirement for heating segmentation also applies to underfloor heating. For example, you are going to the bath and want to turn on the heated floor more strongly. For the user, this function will be limited to entering data on the touch panel, and the installer will need to connect a separate and adjustable underfloor heating circuit. Scripts also work. For example, in the bedroom you can lower the temperature during the day, but raise it in the evening. Similarly with the nursery, where a higher temperature is usually maintained.

If you have a large living room, you can raise the temperature in the reception area by segmenting the heating circuit. But the high temperature of radiators is harmful to flowers; it can be lowered by adjusting thermostatic valves, including automatically, using sensors.

Heating automation in total

So, the level of heating automation will depend on the complexity of the boiler circuit heating system wiring. In some cases, different technologies are used to reduce the cost of installation, avoiding the rise in cost of heating circuits. For example, this is realized with the help of infrared heated floors, which are installed where you need them. At the same time, separate heating of circuits or segments from different heat sources is more expensive to operate. Automated heating is fully realized by pellet boilers that have a built-in multifunctional microcontroller.