Boiler cascade connection diagram: theory and practice

The scheme of cascade connection of boilers is quite realizable even with self-installation. Although our engineers recommend deploying the boiler room after preliminary design. Nevertheless, people without a heating engineering education can realize the type of connection and, accordingly, provide themselves with the advantages of use.

Cascade connection of boilers is used to increase the capacity of the heating system. Its advantage is the commissioning of boilers gradually, as well as the ability to turn off individual units without turning off the heating system.

Boiler cascade connection diagram: organization features

The cascade and connected boilers may differ in the type of burner operation and other characteristics of the heat generators:

- a simple cascade is performed with boilers with one-two-stage burners of the same type;

- a mixed cascade means connecting boilers with different types of burners. For example, for a modulating burner, a complex for controlling the temperature indicators of boiler water is also required;

- modulating cascade - based on boiler generators with modulating burners. The advantage of modulating burners is smooth power control, which allows you to adjust its performance in a wide range of values. It is these heat generators that include solid fuel boilers FOCUS, which are connected by our company in a cascade to obtain boiler houses with a capacity of 2 MW (4 permissible steps of 500+ kW).

The differences in thermal circuits are that in a simple cascade, the power can be adjusted step by step. For this reason, more flexible modulated cascades under the control of a microcontroller are used in industrial environments. Even taking into account the fact that with a cascade of more than 2 stages, the performance of each individual boiler decreases.

Modulated cascade, including that implemented when connected with solid fuel boilers FOCUS, operating mainly on pellet burners, allows you to modulate power steplessly, based on your needs. This significantly reduces fuel consumption and increases the overall efficiency of the heating system. In our case, this opportunity is implemented using a microcontroller. Plum EcoMAX.

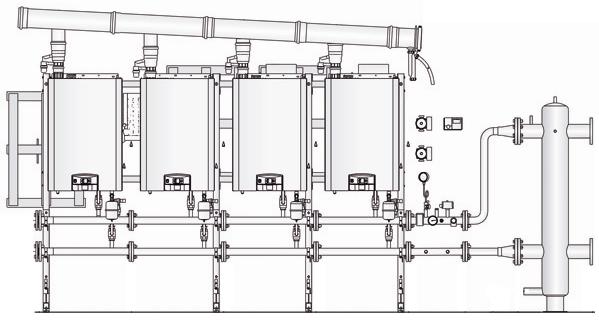

Rice. 1. Directly the scheme of cascade connection of boilers

Modulated cascade and features of its deployment

The use of modulating burners significantly increases the efficiency of the heating system. This is done using a microcontroller. A modulated cascade implies the installation of valves that exclude the passage of the coolant through an idle element of the cascade. This reduces heat loss when the stage is not working. The connection of each boiler also implies the installation of circulation pumps and a pump connection group.

What is a water gun

The modulated cascade is implemented using the supply and return manifolds, including those that exclude the overflow of the coolant between the circuits. In order for the system elements to provide the required hydraulic characteristics, a low pressure hydraulic separator, also called a hydraulic arrow, is used. The scheme of cascade connection of boilers should take into account the intensity of fluid movement in the circuits when selecting a separator model.

A feature of the hydraulic separator is the creation of a zone for reducing the hydraulic resistance. Due to this, the flow rate of the coolant depends only on the speed of the circulation pump in the controlled circuit. The hydraulic arrow provides the hydraulic and temperature balance of the boiler circuits. It provides a constant supply of coolant in the main boiler circuit and allows you to regulate its supply in the second circuit, taking into account the required heat load.

Such a connection diagram with a low loss header is actively used not only in industrial, but also in domestic systems. Especially in cases where high and low temperature heating systems are used. The choice of the hydrosteel is carried out taking into account the power of the boilers and the maximum flow of the coolant into the heating system.

Installation of boilers in a cascade (installation features)

The installation of a cascade of boilers follows the following sequence:

- preparation of the boiler room and installation of fixtures and boilers;

- installation of a fuel supply system, if necessary, drainage and a collector system for the subsequent connection of heating equipment;

- installation of a hydraulic switch, circulation pumps in boiler circuits and a safety group;

- chimney connection;

- commissioning works.

Feature solid fuel boilers FOCUS industrial grade is the supply of equipment with a complete set of connection fittings. Moreover, our company uses only welded victalitic joints... This significantly increases the reliability of the system. The scheme of cascade connection of boilers meets the needs of the client today and in the future use of the boiler house.

The cascading of high-power boilers should be carried out according to a preliminary design. The calculation of the thermal scheme allows you to take into account all the necessary nuances. In addition, these works must be carried out by specialists with the appropriate license and professional admissions. Fulfillment of the connection conditions allows you to create a reliable, efficient and safe boiler house of a compact class, which will provide beneficial economic indicators.

Our specialists work on the basis of their equipment, which we can flexibly integrate into existing boiler houses. If you have any problems with design performance, please contact our engineering department for design work. The scheme of cascade connection of boilers and the subsequent installation of equipment will help to significantly reduce heating costs.

Order a high-performance boiler house from 1 MW

Order installation of a cascade boiler room

Get a cascade boiler house project

Tying industrial heating systems