Compact boiler rooms with Victaulic piping (piping of industrial and domestic heating boilers)

Solid fuel boilers FOCUS shipped with complete Victaulic piping and ready to be connected to the heating system. This is typical for domestic boilers with a power from 6 to 100 kW, available in the manufacturer's line, as well as for industrial models operating in the power range of 100-500 kW. Our company provides deployment services four-stage cascade boiler houses with a total capacity of 2.2 MW. The piping of industrial heating boilers with Victaulic fittings and a system of welded joints can significantly increase the life of any boiler room.

This approach to installation largely solves the problem of corrosion, which is typical for large heat supply facilities. This simplifies the installation of heating equipment on the client's side. Thanks to the mechanical pipe connection using the grooved pipe coupling system, the high-performance compact boiler room can be installed in just a few hours.

Some historical data

The American company Victaulic has made a huge contribution to the engineering of fire suppression, pipeline transportation, heating and water supply systems by offering weldless mechanical pipe joints. The company is the creator and manufacturer of victalitic fittings based on the technology of fastening pipe couplings with grooves. These connections are a real alternative to welding, threaded and flanged connections.

The first surveys in this area were proposed by the company in 1925. Victaulic was founded to manufacture and market bolted couplings. Their feature was the grooves for laying the gasket. When secured, a pressure-sensitive, tight seal is created. The need for such couplings arose during the First World War and made it possible to make quick-fit pipelines in battle conditions.

Initially, the connection was used for military purposes, but found application in engineering systems. First of all, victalitic connections were used to assemble flamethrowers and attach a weapon fire tube. Previously, the structure was falling apart, and hot oil was leaking out, causing serious injuries to the soldiers.

Subsequently, the Victaulic coupling was developed and patented on its basis by engineers. It is now used in the pipeline industry to create safe and anti-corrosion joints.

The principle of mechanical connection of pipes with Victaulic couplings

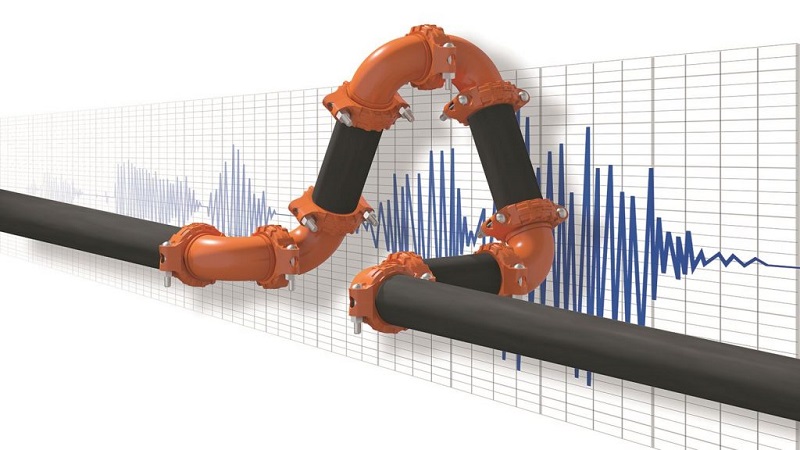

The Victaulic joining system involves rolling grooves to join pipes or pipe components. A groove is also made on the outside of the pipes near the connection. Strong spacers are inserted into the grooves, which are then gripped and clamped by partner joints. As a rule, with couplings. The gasket provides a pressure sensitive seal as opposed to compression joints.

The grooved mounting method offers a simplified yet highly reliable assembly. The absence of welded joints also protects the system from corrosion in the long term.

https://www.youtube.com/watch?v=oeH86POB6fg

Victaulic manufactures a complete Victaulic coupling system. The range of the company also includes specialized compounds that, for example, when damaged, emit a mixture of water and nitrogen to extinguish a fire in the event of a fuel leak.

Victaulic Product Range and Applications

The company produces:

- non-welded connections for pipelines based on Victaulic couplings;

- Victaulic Vortex fire extinguishing system;

- sprinkler heads Victaulic;

- valves with grooves;

- fittings for welded joints;

- compensators.

Solid fuel boilers FOCUS are based on an engineering approach with minimal use of welded joints. For this reason, Victaulic fittings are the preferred piping solution for industrial boilers. FOCUS household models are based on this connection system, which makes them a premium segment. Victaulic is also used in the largest heating and water supply projects.

The main benefits of Victaulic include the following:

- versatility of the mount, suitable for all types of pipes and materials;

- groove (vibration-resistant) connections that can carry shocks in seismically active regions;

- quick repair of connections and their replacement;

- a wide range of fastener models and standard sizes for the design of systems of any complexity;

- user-friendly connection design applications.

While using Victaulic in residential boilers simply ensures long-term operation of premium equipment, in utility and industrial boilers and water systems, it can solve a number of problems.

Benefits of using Victaulic in boilers and pipelines:

- reduction of corrosive effects;

- seismic resistance;

- fittings with fire extinguishing effect can be used;

- high strength of joints and absence of leaks even after decades;

- convenient repair;

- reuse of connections.

Development of projects for boilers and water supply systems on Victaulic valves

Our company can offer to convert any industrial or utility boiler room to Victaulic fittings. This is a separate line of business, the service is offered as part of the development of projects for the deployment of high-performance four-stage pellet boiler FOCUS. We provide reengineering services for utility and industrial heating systems with partial replacement of equipment.

Order a utility boiler room at Victaulic