Common heat accumulators for boilers and their types

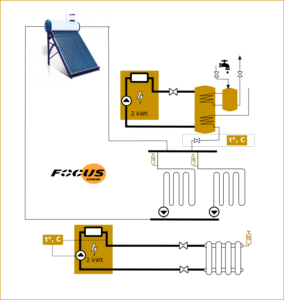

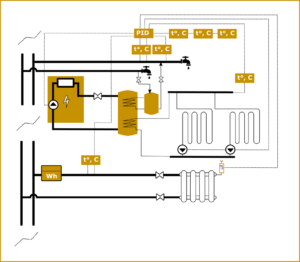

For most heating systems, experts recommend using buffer tanks or a heat accumulator for a solid fuel boiler, in which secondary heat exchange circuits are installed that distribute heat to consumer circuits. It can be hot water treatment, heating of the coolant for radiators or underfloor heating.

Such a heating scheme allows you to achieve not only heat conservation, but also its normalized supply, based on needs. It also compensates for the shortcomings of unregulated solid fuel boilers. The non-adjustability of stoves or conventional solid fuel boilers is the main condition for the use of buffer tanks for storing heat for a longer period and gradual distribution to consumers based on needs, including automated temperature control.

Do I need a heat accumulator for a FOCUS pellet boiler?

Pellet boilers FOCUS have an alternative control principle and are already equipped with a microcontroller that provides a wide range of settings and work in combination with heating automation. A buffer tank for such a boiler is not required, the intensity of the pellet burner is automated.

An exception is hot water treatment and the supply of low-temperature coolant to underfloor heating. This is realized by the secondary heating boiler, which is shown in the wiring diagram.

How to choose a heat accumulator for a boiler and on what basis

The choice of a heat accumulator is carried out depending on the availability of models and the heating scheme that is planned. Accordingly, the selection of heating equipment can be made on the basis of a heating project or with the help of an experienced installer who also knows the features of the proposed models, depending on the manufacturer and price.

Despite the fact that FOCUS pellet boilers do not require the use of a buffer tank, except in the form of a secondary heating tank for hot water treatment, we will tell below what buffer tanks exist and how they differ.

Types of heat accumulators for boilers

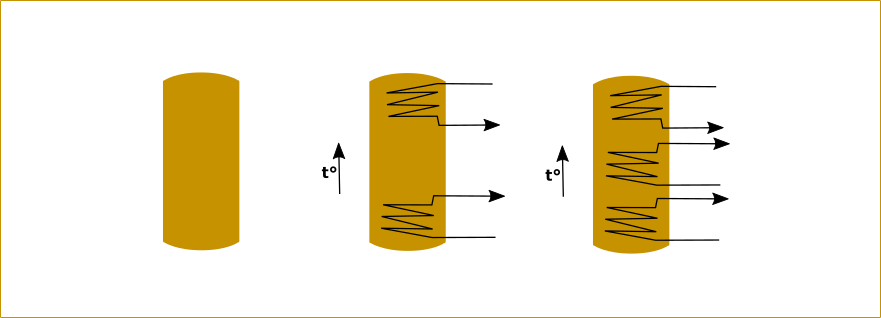

You can accumulate heat in different ways, this is well demonstrated types of heat exchange circuitsthat were discussed earlier. The same applies to heat storage devices. The most common types include the following.

Heat accumulator tank: barrel with insulation

When developing buffer tanks in storage tank format, many hydraulic characteristics are taken into account. But, in fact, this is a barrel, made of ferrous metal or stainless steel with an outer layer of insulation. Basalt wool 50-100 mm is usually used, in more expensive variations polyurethane foam is used. The better the insulation, the longer the heat is retained.

The buffer tank with heat exchangers implies self-insulation. Such models are cheaper, belong to budget heating equipment, but require additional work during the installation process, on which the heat storage efficiency will depend.

Heat storage tanks work on the principle of a secondary heating boiler. That is, they have branch pipes of heat exchangers. There are various configuration options on sale, but pipes for underfloor heating, hot water and heating are traditionally provided.

For radiators, the pipe is installed at the top of the barrel, where the water temperature is higher. From the nozzles in the middle part, water is discharged either into warm water or for hot water supply. The same applies to the circuit in the lower part of the drum, where low-temperature heating is provided.

High-quality models of heat accumulators include an inspection flange, which contributes to the care of the heat exchange tank. Details are covered in our other article on the benefits of using buffer tanks.

Secondary heat exchange circuit for hot water supply

This is a special type of heat accumulator, which is usually equipped with one coil heat exchanger. It is necessary for heating hot water in systems with pellet boilers FOCUS. According to the format, we are talking about a flow-through water heater, near the walls of which a coil circuit is placed, which prevents bacteria from settling.

Such a heat accumulator can be used for hot water treatment in summer from solar collectors. This organization reduces costs. The contact heat exchanger is necessary so that the heat carrier medium of the solar collectors does not mix with running clean water.

Depending on the location of the coil, it may have different functions, and there may be more than one coil in one reheat tank. The coil on top, respectively, takes away the heat of the coolant. The coil at the bottom is designed to take away the heat of the equipment - a solar collector or a heat pump for a heating system or hot water supply.

There can be two DHW circuits with different functions, depending on the operation of the secondary heating tank. They can be connected manually and represent the "summer" and "winter" water treatment circuits.

Heat accumulator for a tank-in-tank form factor boiler

According to this principle, water is heated using a boiler, when the main coolant is accumulated in an external tank and fed into the heating system through a single pipe. The secondary heating boiler provides, respectively, hot water supply.

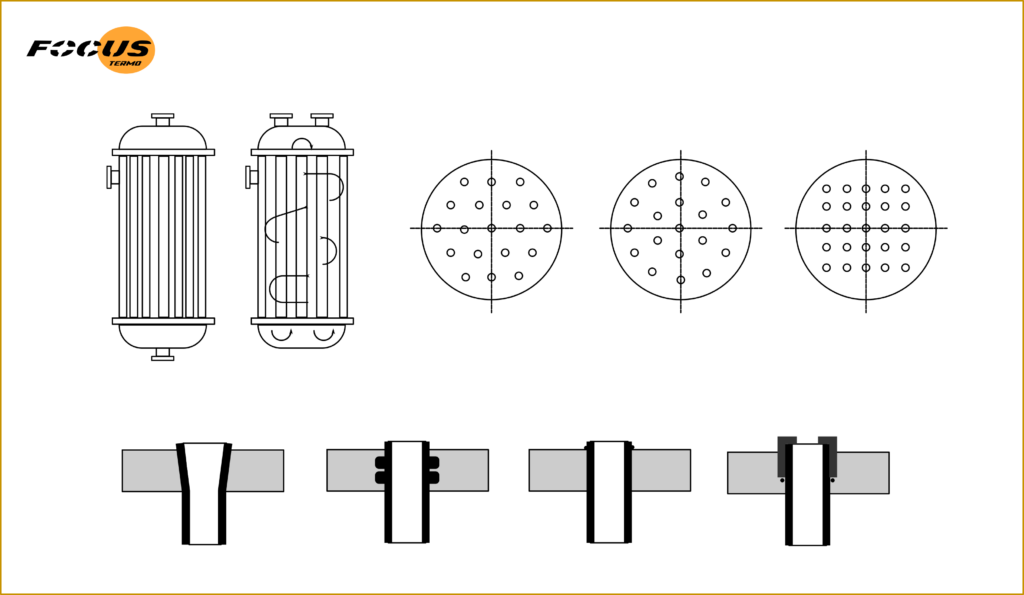

The peculiarities of the form of such heat exchangers is a ribbed surface to remove scale and increase the heat exchange area.

Block-type heat exchanger in the tank

An alternative to the coil is a block corrugated heat exchanger. The advantage of this design is flange mounting and easier maintenance. High thermal conductivity is an additional advantage, which is important for underfloor heating and hot water, which must be heated by solar collectors.

The corrugated pipe and the corrugated block heat exchanger self-clean from scale due to thermal expansion.

Heat accumulator with heating element

This, one might say, is an option and a compensating heat source in heating systems with a solid fuel boiler. For example, you are not at home and turn on the heating element, it heats the rooms for you up to 12-15C. Electric heating is also necessary for the elderly and children. The heating element can turn on when the temperature of the coolant drops in the presence of a sensor. This is convenient for the time when you do not have time or cannot flood the boiler.

The basic principle of operation of such a heat accumulator for a boiler is to install a heating element in a familiar buffer tank. In some cases, several pieces are installed.

Buffer tanks for the boiler can be of different shapes

Thermal accumulators are manufactured in different shapes and form factors: horizontal, rectangular. But they are not used for heating systems, as they do not hold pressure. Commercially available flat heat accumulators do not have welded seams; this is a very important factor in the lack of maintenance during long-term operation.

Buffer containers made to order or handmade

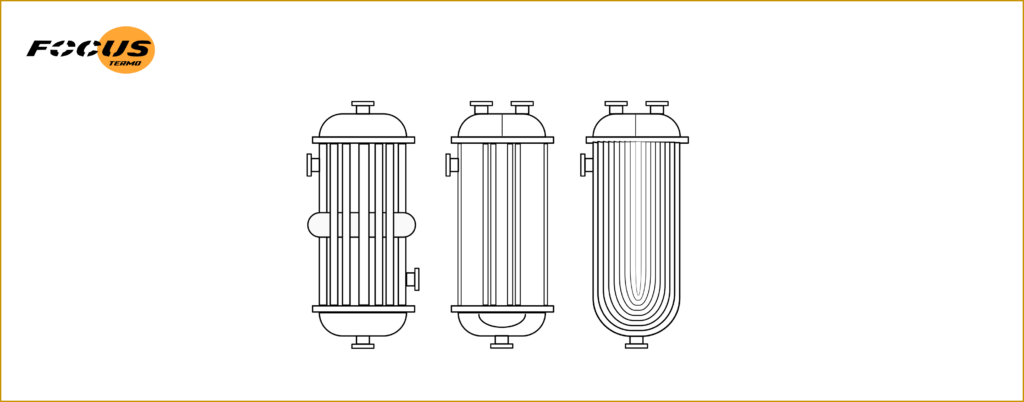

In some cases, a heat accumulator for a boiler can be made to order. Coil heat exchangers are commonly used, but solutions vary. Here are several types of heat exchangers that can be installed in a buffer tank.