Features of heating and installation when installing FOCUS pellet boilers

Today we will look at the heating and installation features when installing FOCUS pellet boilers. First of all, we note that we are talking about automatic heating of the room with temperature regulation by an installed climate control system. It can work according to a minimal algorithm, controlling the operation of a pellet boiler, or serve the entire house.

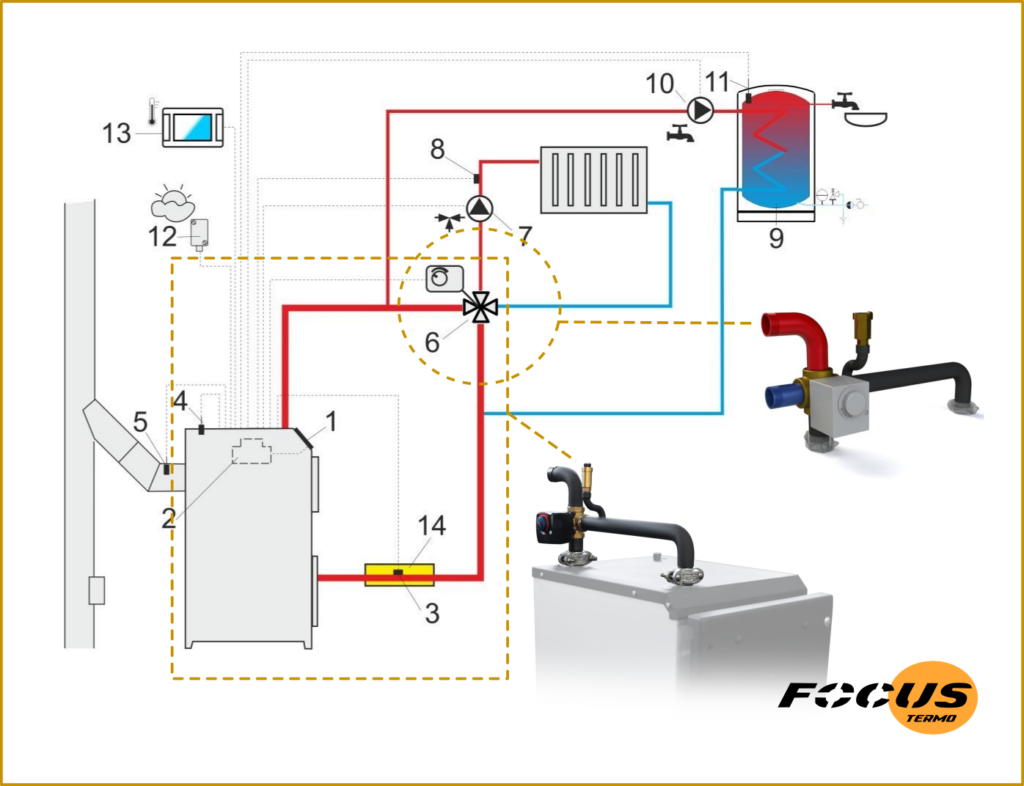

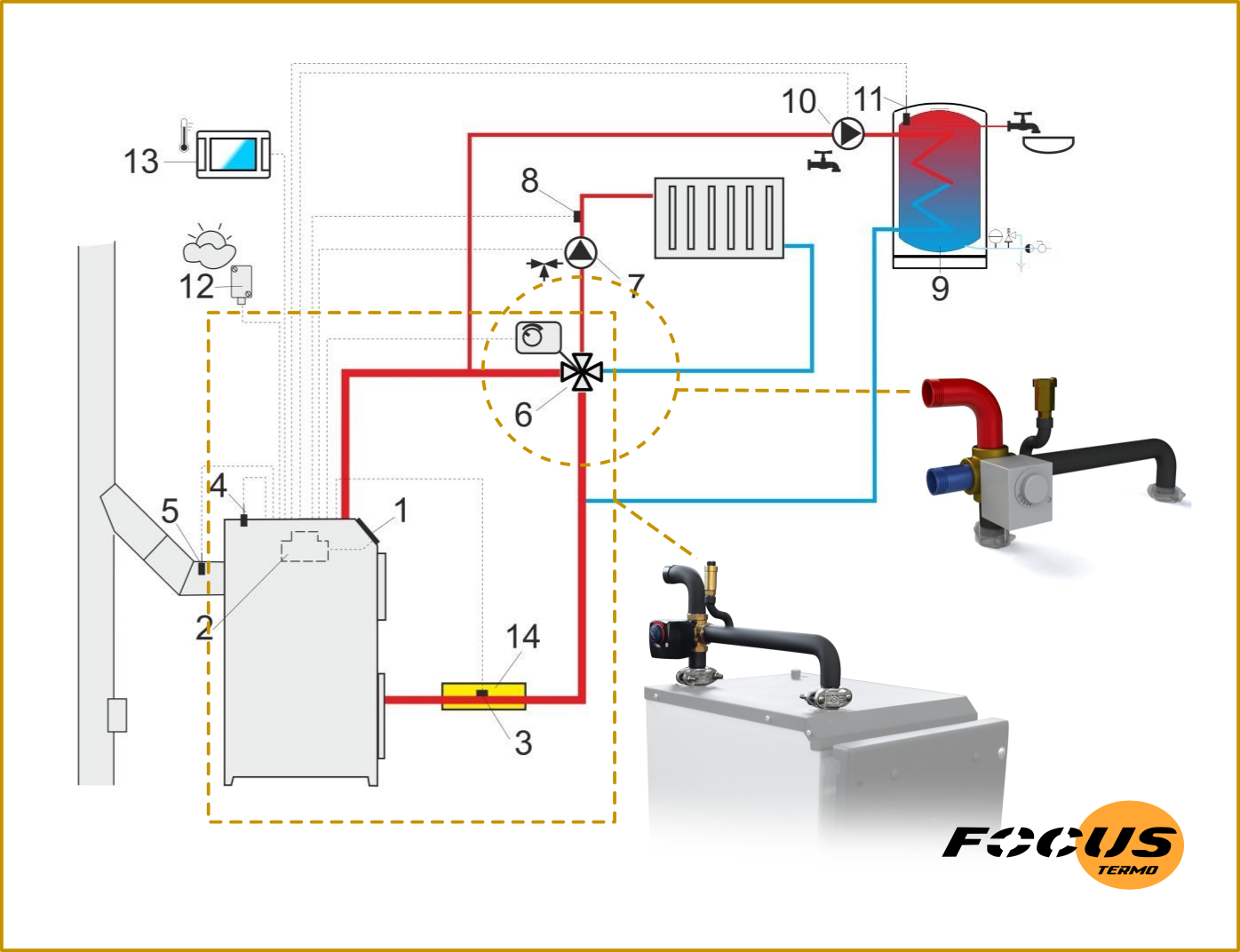

Also, FOCUS heating equipment is aimed at servicing the industrial segment; FOCUS boilers for households belong to the semi-industrial class and are characterized by increased reliability. A distinctive feature is the supply hydraulic piping kits “groovelock” based on Victaulic connections and pipes. This fitting allows for quick installation of the boiler using screw couplings with maximum quality and safety.

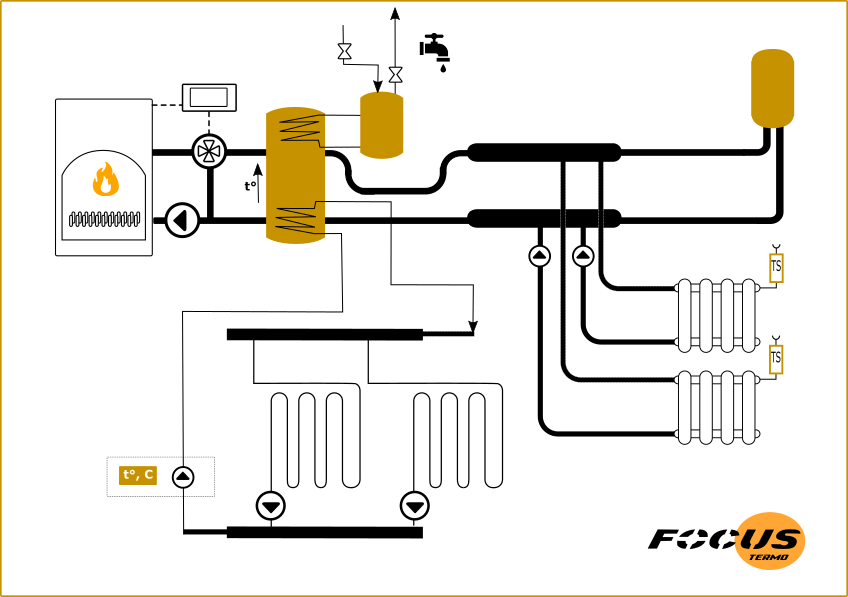

Heating and installation of a system without a buffer tank

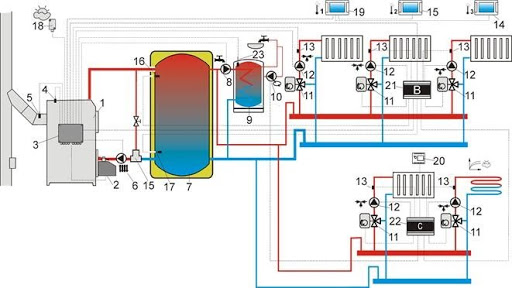

It is known that one of the methods and schemes of hydraulic isolation is the use of an insulated buffer tank or heat accumulator. The design features of such tanks are different, but the general principle is to combine heat exchange circuits, which were written about earlier.

The principle is that the coolant heats a heat exchanger that carries another coolant. This is due to the fact that it is necessary to accumulate heat in an unregulated volume, which is generated by solid fuel boilers or stoves during manual loading. In addition to the accumulation of heat in the buffer tank during unregulated heating of the coolant, sometimes to critical temperatures, a safety problem also arises. First of all, the safety of coolant transfer between subsystems not designed for such a temperature.

Adjust the coolant temperature using temperature sensor A buffer tank or a controller for solid fuel boilers with manual loading helps. With its help and piping with a three-way valve, they organize the admixture of cold water into the circuit with the hot coolant. Such a system also takes place in pellet boilers, but its task is to protect the boiler from abnormal states of the coolant from the return circuit and to connect hot water supply and warm water.ly as a low temperature circuit, although this can also be done by wiring with a three-way valve.

In other words, recommended pellet boiler connection diagrams A buffer tank is included in the heating system, but it performs other functions. More details in the publication.

Heating and installation of a system with pellet boilers

The FOCUS pellet boiler is a solid fuel boiler with an installed torch-type pellet burner into which pellets are fed; it burns with high heat output thanks to volumetric combustion technology. Burner operation is controlled microcontroller PLUM with weather regulation.

The automation switches on equipment with automatic ignition when the temperature outside and in the house drops and turns it off if necessary. For the main period of time, the automation regulates the intensity of the burner; for this reason, a buffer tank is not needed. The addition of water is ensured by a microcontroller-controlled three-way valve in order to maintain nominal temperatures in the system. FOCUS-Victaulic hydraulic kits available for purchase.

Technical side of the issue

Maximum efficiency in solid fuel boilers is achieved in a narrow temperature range: in hot mode, when the supply is in the range of 75-85*C, the return is at least 65*C. Moreover, this range is the most efficient in terms of efficiency, when very little remains before the coolant boiling zone.

The power of such boilers varies, but the main disadvantage is the narrow zone of stable operation. As a result, a safety problem arises, including the well-known problem of rapid extinguishing, when it is impossible to suddenly remove heat from the burning fuel so that the boiler does not go out of the normal operating range.

In this case, the method of “discharging heat” into the buffer tank is used. De facto, the heat accumulator provides the required level of safety, not efficiency. You can, of course, avoid the safety problem to some approximation by installing cast iron radiators and durable metal pipes. Economy and ease of adjustment are options for the main operation of the buffer tank.

In a pellet boiler, this problem is solved by automatic ignition and extinguishing, so a buffer tank is not required. The microcontroller also works with pump groups serving radiator heating circuits, equalizing the temperature with the flow of coolant. More fine-tuning can be done on the basis of a heated floor, regulating activity using the climate control system. Moreover, this is possible even in systems with boiler with manual fuel supply.