Possibilities

Modern requirements of ecology and production culture require appropriate solutions, special attention is paid to the cleanliness of emissions into the atmosphere from pellet boilers, An important factor is the possibility of reducing emissions and optimizing the combustion process compared to gas and diesel heating.

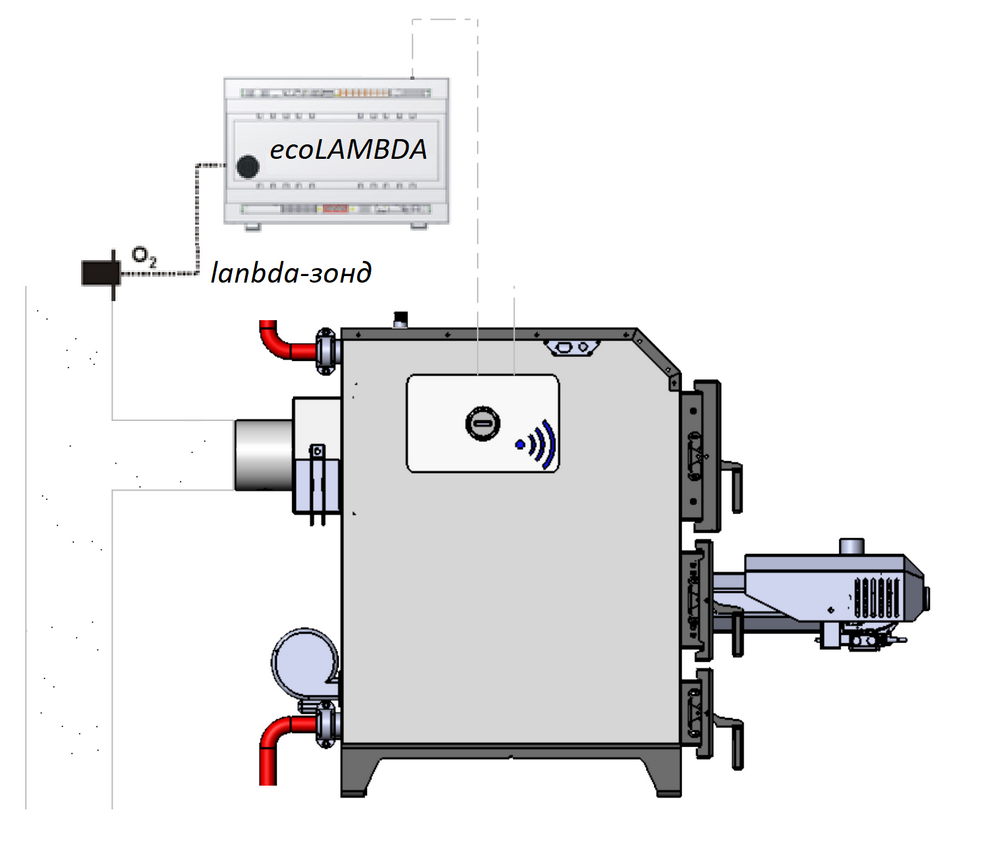

The controller with a lambda probe built into the boiler automatically corrects the operation of the pellet boiler pressurization fans or the pellet burner built into the existing boiler, optimizing the fuel combustion process, which, on the one hand, excludes too much air supply for combustion, on the other hand, minimizes the emission of carbon dioxide into the atmosphere, allows not only to reduce the cost of heating by optimizing the fuel/air ratio, but also to ensure a high level of purity in the emission of flue gases from carbon dioxide. In parallel, the controller monitors the temperature of the outgoing flue gases, adjusting the power of the pellet boiler or pellet burner to maintain optimal power, keeping the power at the level of the capabilities of the boiler itself as a heat exchanger, without excessive fuel consumption.

The principle of operation of the controller

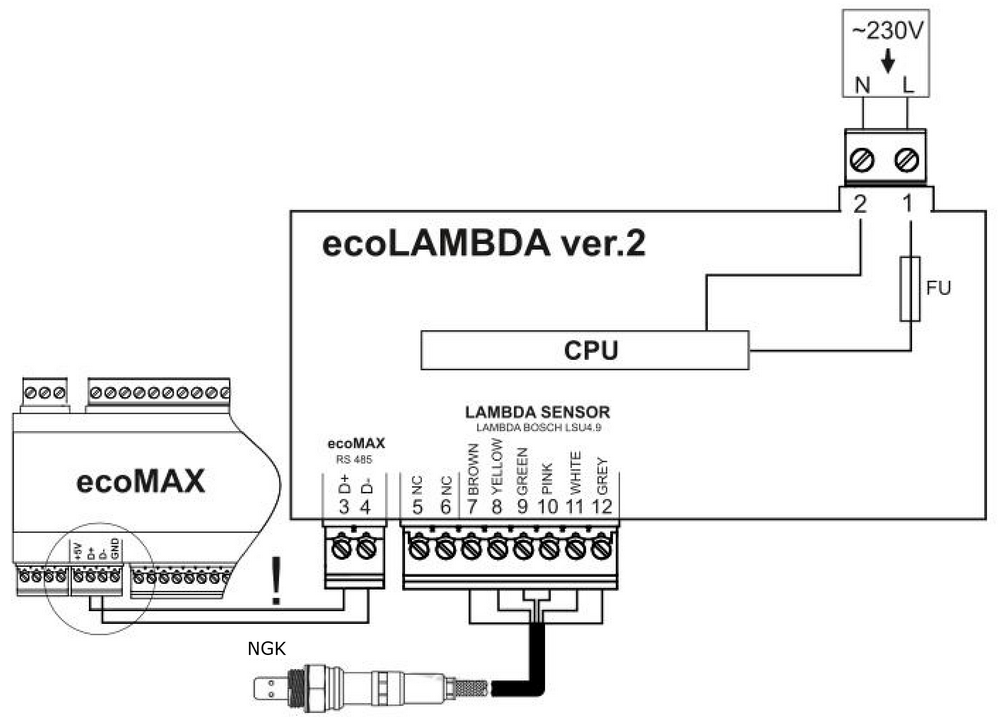

The controller corrects the operation of the main control unit of the pellet boiler or burner (ecoMAX 850 and ecoMAX 860), which in turn controls the operation of the fans installed in the boiler and / or pellet burner, while simultaneously controlling the oxygen level in the flue gases. In the case of fan control to correct the level of excess oxygen, the proportions of the primary and secondary blowing of combustion air can be controlled. In case of excess - reducing the proportion and performance of blowing fans, with a shortage - increasing the proportion and performance of blowing fans, trying to maintain optimal performance. During the initial setting, the proportion of excess oxygen and the level of carbon dioxide emissions is optimized using a flue gas analyzer, then it is automatically maintained by the controller independently according to the level of excess oxygen in the flue gases. The power of the pellet boiler or burner is also corrected according to the flue gas temperature. If the temperature is too high, the thermal power is limited, if the flue gas temperature is too low, the power is increased. At the same time, the main control unit ecoMAX monitors the set temperature of the heat carrier and does not allow it to be exceeded, independently limiting the heat output of the pellet boiler or burner, maintaining the set temperature of the heat carrier. As a result, a balanced control system is formed that maintains the optimum output of the heating circuit, automatically maintains the ratio of combustion air to actual fuel consumption and emissions into the atmosphere.

Reviews

There are no reviews yet.