To use or not to use the buffer tank with the pellet boiler?

Today we will analyze the technical question, should I use a buffer tank with a pellet boiler? In general, the installation of a solid fuel boiler without a program-controlled pellet burner and without a buffer tank, it is extremely dangerous and not economically viable, since in the smoldering mode the efficiency of a hard top drops rapidly, especially for boilers with afterburning of combustion products, which in theory should be more efficient than conventional ones.

Pellet boiler controlled by a microcontroller, so the use of a buffer capacity is technically impractical. But why? And why is an automatic boiler often cheaper than a well-made manual boiler?

A few words about solid fuel boilers

As we wrote earlier - everything solid fuel boilers (TT-boilers) to achieve maximum efficiency operate in a narrow range of temperatures and capacities. The range width for different types of TT boilers varies, but all the same, the main drawback is the narrow zone of stable operation. This problem is almost invincible and is the main problem of solid fuel heating.

The second and essential problem arising from the first is security. The stacking of fuel in various types of combustion (upper, lower, long-term, pyrolysis and the like) has a common drawback - the fuel cannot be extinguished quickly. The masonry warms up, pyrolysis gas (thermal decomposition gas) is released, which burns to generate heat. For some solid fuel boilers, the gas burns up, for some it burns down, which does not significantly affect the controllability of the process.

In the event of a power outage or if the heating system is unable to extract all the heat released from the fuel filling, the boiler temperature inevitably begins to rise. The options for solving this situation are varied, but they all boil down to a simple idea - this is heat loss. And, as the most cost-effective way, the most optimal way is to dump heat into the battery or buffer tank (depending on the tasks). It is the volume of this container that is a kind of - a guarantee of safety, and not efficiency, which allows you to reset excess temperature.

What about objections?

Closing the blower

Even completely closed air blowing into the boiler does not extinguish the fuel and heat continues to be released. If in domestic boilers and furnaces this process has a controlled destructive effect, then in industrial and semi-industrial versions everything is much more complicated.

It is precisely because of the safety and economic component in the disposal of excess heat that buffer and heat storage tanks have become widespread.

Moreover, a conflict arises - the TT boiler works optimally in hot mode, when the supply is in the range of 75-85 * C, the return is at least 65 * C. At the same time, a small margin is the most efficient in terms of efficiency, when there is very little left before the boiling zone of the coolant. At this moment, the fuel burns most efficiently, but the flue gas temperatures also increase (the efficiency decreases with emissions to the street).

Excess heat, as we have already written, is safely discharged into a heat accumulator. With the closing of the air intake, the situation can be aggravated by the fact that a lot of unburned carbon appears in the furnace, which is precisely the basis of tar and tar on the walls of the boiler and chimney. With enough of it, the chimney can flare up, which can lead to a fire, destruction of the chimney structure, and other negative consequences. That is, extinguishing the boiler in this way is not recommended and even dangerous under a certain set of circumstances.

Objections backed by history

There are a lot of craftsmen among the people who are trying to prove that boilers without a buffer tank are not dangerous, they can be successfully operated, they give a lot of examples. But the regulatory framework and the rules for the operation of solid fuel boilers - work without a buffer tank is strictly prohibited. This is labor protection, written in the lives of people, and engineering calculations and economic justifications.

So should you use a buffer tank with a pellet boiler?

We are often as producers pellet boilers we encounter the opposite opinion when the standards of the classical norms of TT boilers are applied to the pellet boiler. Namely, this is the need to install at least a buffer tank and a heat accumulator. This misconception often pushes people to additional costs for no apparent reason. A pellet boiler with a burner is controlled by a microcontroller, which provides instant extinguishing of the boiler or a reduction in the intensity of combustion.

The bottom line is simple - for the normal operation of a pellet boiler or a pellet burner installed in a TT boiler, the installation of additional heat accumulators or buffer tanks is not required, unless otherwise provided by the project and the needs of the heating system.

For example, in greenhouse complexes, to compensate for a sharp drop in temperature, it is simply vital to install a capacious heat accumulator, but this is not necessary for pellet burner. In addition, the buffer tank is installed as a secondary heating boiler for domestic hot water, but again this does not apply to technical requirements.

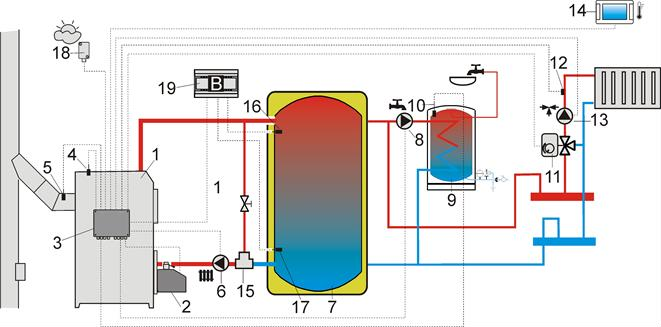

Hydraulic connections with buffer tank and indirect heating boiler

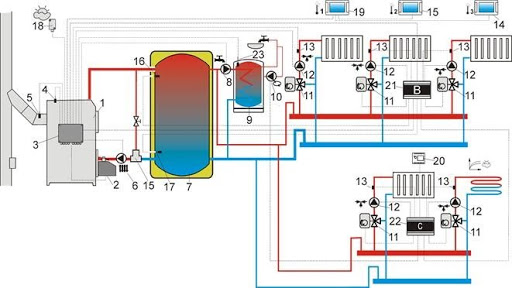

Examples of hydraulic decoupling when installing pellet boilers

Examples

Let's take a simple example. A household boiler weighs an average of 200-300 kg. When the power supply is turned off, there is approximately 300-500 grams of fuel in the pellet burner nozzle (let's take it with a margin of 50 kW), which, under ideal circumstances, can produce a maximum of 2.5 kW of heat. This energy is enough to heat a mass of 300 kg from 85*C to 92*C (i.e. only 7*C).

Approximate calculation does not take into account the loss of heat with flue gases, reduced combustion intensity in the absence of intensive fan blowing, and in any case, microcirculation present in the system. All these factors will narrow the already small delta of stable operation. That is, we see that even in the most difficult case, the situation cannot get out of control. At the same time, the automation of the pellet burner has a number of additional protection systems against overheating of the boiler, and we also take into account the mandatory presence of relief valves.

All these factors and the exact dosage of fuel with modern automation equate the flexibility of a pellet boiler, its automation, and the response to a change in the heating system to a gas boiler, which itself does not require a buffer tank.

From this it follows that in a pellet boiler room there is no need for most devices inherent in a manual loading boiler room!

Read also about types of heat accumulators.

Best regards - FOCUS team