Budget fittings for boiler rooms. Valves and accessories

Recently, we talked about pumping groups that are used for piping boilers with guaranteed quality. But this is not the only way to establish boiler and related equipment. Today we will talk about what fittings for boiler rooms are produced, and for what purpose it was made. First of all, we note that without exception, all reinforcement assemblies, fixtures and accessories are designed to facilitate installation. They will be discussed in our today's review.

The more you use a variety of fittings in heating systems, the more functional it will be. Moreover, such valves and regulators allow you to automate the heating system.

Heating system fittings

Most of the available boiler fittings are for horizontal wiring. Manufacturers pay close attention to their development and modification. In fact, manufactures offer a complete installation system, so armed with a catalog, you can choose everything you need to tie your boiler room. But masters rarely do this, purchasing items "from the collection" by the piece. In turn, fittings for boiler rooms are represented by the following types and piping units.

Security groups

For installation boiler a separate circuit is piped, in which a so-called safety group must be present. It consists of an air vent valve, a pressure gauge (pressure sensor) and a safety valve that controls the pressure and removes its excess.

We have listed the main fittings for this assembly group. Their set may differ depending on the functions and the manufacturer's vision of what should be included in it. For example, a safety group can remove slag or have a thermostat.

Pre-regulated valves

We have devoted a separate review to balancing valves. "How to equalize the temperature in radiators"... This unit, as you know, regulates the pressure in the circuit and removes its excess. The control valves can also be used to change the constant temperature in different segments of the heating circuit. This is especially necessary to do in long heating branches, in the tail of which the cooled coolant accumulates.

Control valves are represented by a wide range of equipment, it also includes:

- control valves with shut-off function;

- valves with thermostatic head and bellows for temperature regulation;

- multi-way valves with and without thermostatic head.

The list of equipment allows you to achieve balanced design characteristics, as well as minimize the impact of certain features of heating systems. For example, in radiators, adjustments must be made to achieve the same temperature in all heating circuits. This is done using valves.

Distribution gearboxes

With the help of reducers, the required number of branches of the heating system is set. This reduces the number of different adapters and makes the wiring more understandable and technologically advanced. Better repairable if needed.

The most used fittings for boiler rooms include: reducers, plugs, ball valves, check valve and thermostat.

Boiler room fittings and their types

In general, valves and fittings include several main product categories:

- balancing valves;

- air vents;

- collectors;

- cranes;

- check valves;

- safety valves;

- pressure reducers;

- thermostats;

- mixers;

- three- and four-way valves;

- make-up valves;

- thermostatic valves;

- anti-condensation valves;

- overheating protection valves and others.

Depending on the tasks, the heating system can have a different piping. Let's try to analyze what fittings for boiler rooms are used for these purposes.

Heating boiler piping

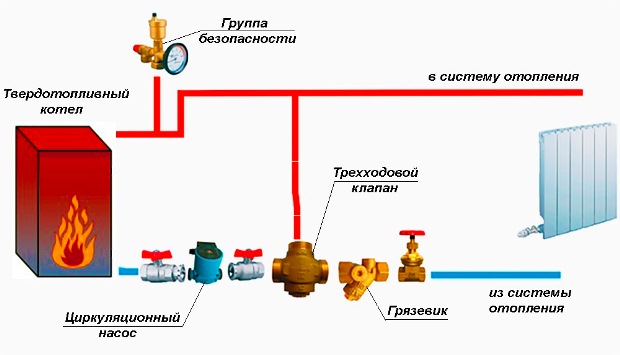

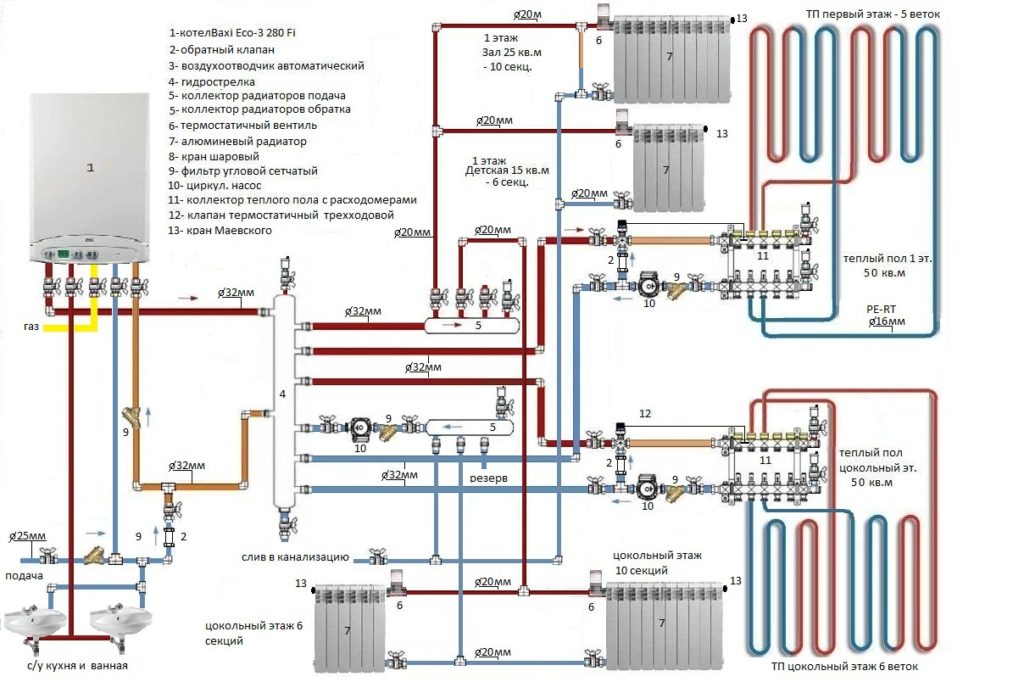

To understand what kind of reinforcement is needed, for strapping, let's compare two thermal schemes. One simplest one for connecting a solid fuel boiler. The second is designed for piping a real heating object.

In general, the installation of the boiler requires:

- a security group that is mounted as a separate node;

- forced circulation pump with bypass;

- shut-off valves for bypass;

- three-way valve;

- mud filter;

- a balancing valve can be installed in the additional line to relieve excess pressure in the supply line.

To connect a gas heating boiler to the system through a hydraulic arrow, you will need the following fittings for boiler rooms:

- in the supply pipeline with a diameter of 32 mm, going to the hydraulic switch, only a shut-off valve is installed on this line;

- “On the return line” a mud filter is installed, which prevents slag and impurities from entering the boiler;

- make-up line is equipped with a dirt filter;

- a check valve is required at the connection of the make-up line and the "return" to avoid the overflow of the coolant;

- an additional angle mesh filter is installed on the make-up;

- several shut-off valves are also required.

The safety group for gas boilers is not installed, it is included in the built-in boiler kit. In the case of a solid fuel boiler, a safety group and an expansion tank are installed on the supply line.

Extended strapping solid fuel boiler

When installing a solid fuel boiler, experts recommend installing an extended set of fittings for boiler rooms:

- safety valve to protect the circuit from high pressure. Its model depends on the power of the boiler. For boilers up to 50 kW, the safety assembly is installed with ½ ”by ¾” outlets. Such assemblies allow static adjustment if the factory does not fulfill its functions;

- the safety valve can be installed as part of a safety group or separately. But the usual pressure corresponds to 3 bar, when installing with solid fuel boilers, it is worth replacing it and setting the nominal value corresponding to the characteristics of the boiler;

- an emergency cooling valve is required when the boiler circuit overheats, it is installed on the coolant supply;

- in the "return", by analogy, an anti-condensation valve is installed to protect against a cold heat carrier;

- the make-up line should preferably have an auto-make-up valve;

- the automatic air vent is included in the safety group, but can be installed directly.

In this configuration, the piping of the solid fuel boiler will be complete. It will ensure the safe operation of heating equipment even in emergency situations.

Buy a solid fuel boiler with installation