Utility DHW automation: new and classic possibilities

Automation of hot water supply systems consists in maintaining the normalized temperature at the points of its intake. Usually it is 60 ° C. This is realized with the help of individual hot water devices at the points of consumption or allows water to be supplied from a central system. At the same time, hot water treatment is traditionally carried out in local heat exchange units. We are talking, of course, about communal water supply systems. But the approach can be implemented for a separate apartment or house, when the heating boiler is automatically turned on in the absence of communal hot water.

The general principle of operation of the communal DHW system

Despite the fact that individual water regulators installed at the points of its intake are considered ineffective, this approach makes it possible to make an independent heat supply system from centralized outages. However, individual regulators are only installed on rare occasions. Typically, public water supply systems are connected to the central heating network through water and steam-water heaters. Automation of hot water supply systems consists in maintaining fluid parameters.

Water temperature control is provided using a conventional thermostat working in conjunction with a control valve. It has two inputs, where the direct and return water supply lines are supplied, the outlet branch pipe is connected to the water supply line. When the temperature rises above the standardized, chilled water is supplied through the return line. In the case of a decrease, on the contrary, the hot water supply from the central DHW system is increased.

If there is a local regulator, the water temperature is monitored and maintained using the installed water heater.

Maintaining the water temperature by circulating the system

DHW are divided into systems:

- with water circulation;

- without water circulation.

In the second case, with an insignificant water intake, the water in the system is cooled and needs to be drained to an acceptable temperature. To eliminate this effect, a centrifugal pump is installed locally to maintain circulation. When the temperature in the system drops to 45 ° C, the triggered regulator starts the pump, while heating the water in the boiler is turned on.

When the water temperature is brought to the standardized values of 60-65 ° C, the regulator again works and turns off the pump with a water heater. Also, in some cases, the hot water supply support is turned off at night.

Temperature maintenance in open and closed systems

Heat accumulators can also be installed in the system, with the help of which the temperature of the water in the system is maintained. But the details of the operation of the DHW communal complex depend on the specific hot water supply system and the type of system (open or closed). Automation of hot water supply systems is also carried out based on the characteristics of the system.

In an open system, when the temperature changes, the volume of water supplied from the network changes, the flow separation is provided by a three-way valve. Thus, mixing the required volume of hot and cold water is achieved. The approach provides a constant water intake from the network, which eliminates the violation of hydraulic regulation.

But the constant intake of water leads to an increase in the temperature in the return pipeline, which results in an increase in the cost of consumed heat. When connected to a CHP plant, this is undesirable, since in this case the power generation by the station decreases with an increase in heat consumption.

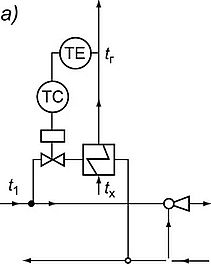

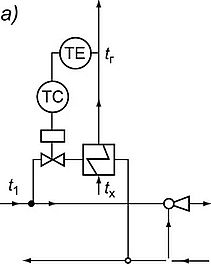

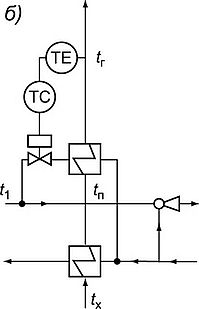

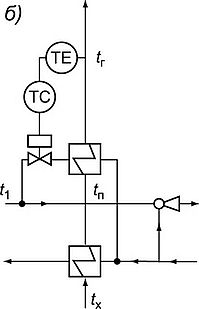

|   |   |   |

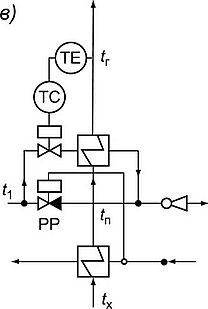

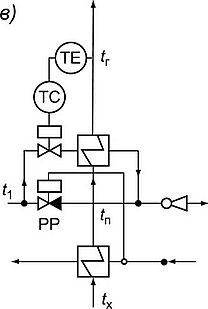

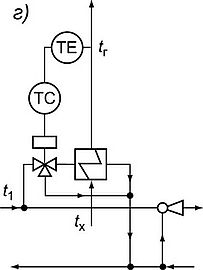

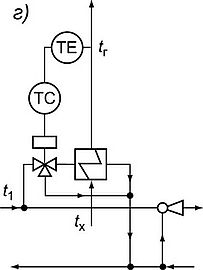

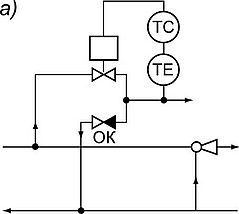

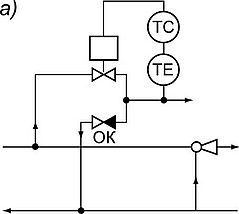

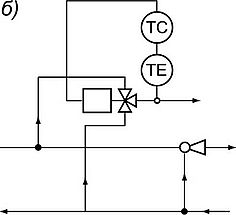

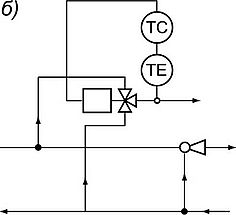

Rice. 1. Scheme of hot water supply with automation in a closed system (a - parallel; b - mixed two-stage; v - two-stage sequential; d - diagram with a three-way control valve). ТС - temperature regulator; РР - expense accounting; TE - temperature sensor.

In an open DHW system, water is supplied directly to consumers. The temperature is regulated by the mixer from the forward and reverse flow of the DHW system. In open systems, the popular design is with a direct flow control valve and a return flow control valve, as well as the use of a three-way mixing valve.

|   |

Rice. 2. Scheme of hot water supply with automation in an open system (with two-way (a) and three-way (b) control valve).

DHW automation in residential consumption

In the apartment, the connection of backup water heaters can be automated in the absence of hot water in the network. Including, the supply and heating of liquid from the cold circuit, and in the conditions of an individual residential building from the storage tank. Automation allows you to switch consumption automatically and without user intervention.

At the same time, accounting is made for hot water intake from the utility network using a hot water supply meter. Automation of hot water supply systems for apartments and houses consists in the use of automatic consumption systems. For example, switching on a bathroom set, as well as controlling the temperature of the water in the circuit.

The automation system can also include solenoid shut-off valves. They allow you to turn off the water supply system remotely during accidents. In this case, a leakage control system is installed in the bathroom and in the toilet, transmitting data via Wi-Fi. With its help, you can minimize the risks of domestic accidents.

Order a project for industrial heating and hot water supply