Automatic pellet boiler Mono-pellet 50 kW FOCUS

Economical heating pellet boiler Mono-pellet 50 kW FOCUS (5-55 kW) for household needs and heating of relatively small rooms. If you need 8-15 kW (75-140 sq. area) to heat a small house, then this version of heating equipment will help to heat up to 250 sq. meters of rooms with a ceiling height of 2.5 m in automatic mode.

Pellet boiler Mono-pellet 50 kW TM "FOCUS" is included in a special series of heating equipment developed for the household heating segment and small business premises, small production premises and workshops. The proposed equipment is designed for heating at maximum capacity of premises up to 500-550 sq. meters, while operating in automatic mode and accompanying the operation of any complex heating circuit.

The emphasis in the development and production of the boiler was placed on the efficiency of heat removal, specifically when working with a flare pellet burnerThe boiler operates on pure wood pellets with an ash content of up to 1% according to EU standards and on ash (agro) pellets with an ash content exceeding 10%, while ensuring complete combustion of combustion products and, accordingly, environmental characteristics.

To maintain the efficiency of heat exchange, there is a mechanical self-cleaning function for the grate, as well as automatic ignition with flame control by its glow, for automatic connection of the boiler when the air temperature drops.the automatic system literally sees the flame and maintains it independently. This combination of functions has become the basis for economic benefits and expediency when purchasing. At the same time, simple and economical operation of the equipment is ensured when using commercially available ash fuel pellets.

The main advantages of the pellet boiler Mono-pellet 50 kW:

- Touch control panel with intuitive interface: Easy to set up and manage, convenient to use even for untrained users.

- Convenient cleaning of the pellet burner: The movable grate automatically dumps ash, an optical sensor monitors the presence of flame, and automatic pellet feeding and smooth temperature control help manage fuel efficiently.

- Efficient heat exchanger: Well-developed convective part in combination with horizontal heat exchanger provides maximum heat transfer and fuel economy.

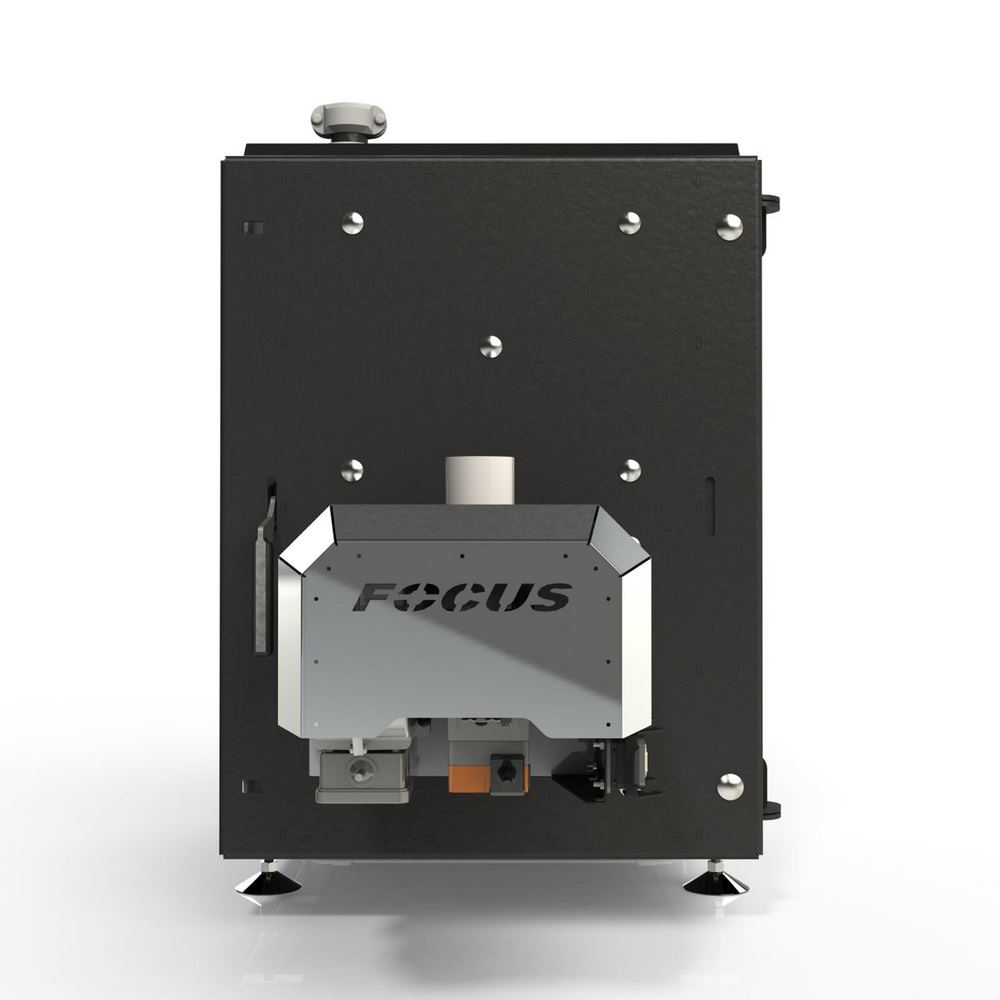

- Hybrid heat exchanger: The combination of plate and tube heat exchangers helps to effectively absorb infrared radiation and simultaneously serves as an ash filter.

- Big ash pan: The increased ash pan volume allows for trouble-free operation on high-ash fuel, reducing the need for frequent cleaning.

- Thermal stress relief system: The plate heat exchanger protects the structure from the point impact of the torch, settling heavy particles of volatile substances.

- Ease of maintenance: A wide hatch provides convenient access to the heat exchanger for cleaning, and the horizontal system and ash chamber in front of the chimney make maintenance simple and quick.

- High capacity ash pan: The boiler is designed for industrial use and is capable of operating on high-ash pellets without the problems typical of foreign models.

- Flexibility of hot water supply connection: Threaded connections for connecting a heat exchanger or indirect heating boiler with the possibility of using a hot water supply temperature sensor.

Automatic pellet boiler Mono-pellet 50 kW offers a high level of convenience, efficiency and reliability for solving heating problems on various types of pellets.

Design features of the FOCUS boiler:

- Boiler material: Structural steel 09G2S, which ensures reliability and durability.

- The thickness of the walls of the heat exchange part (furnace and primary heat exchanger) is 6 mm.

- The thickness of the outer shell of the boiler water jacket is 4 mm.

- Heat exchanger surface area: 3.4 m² (including fire tube heat exchanger), which ensures high heat transfer efficiency.

- thermal insulation: 50mm thick basalt mineral wool, preventing heat loss.

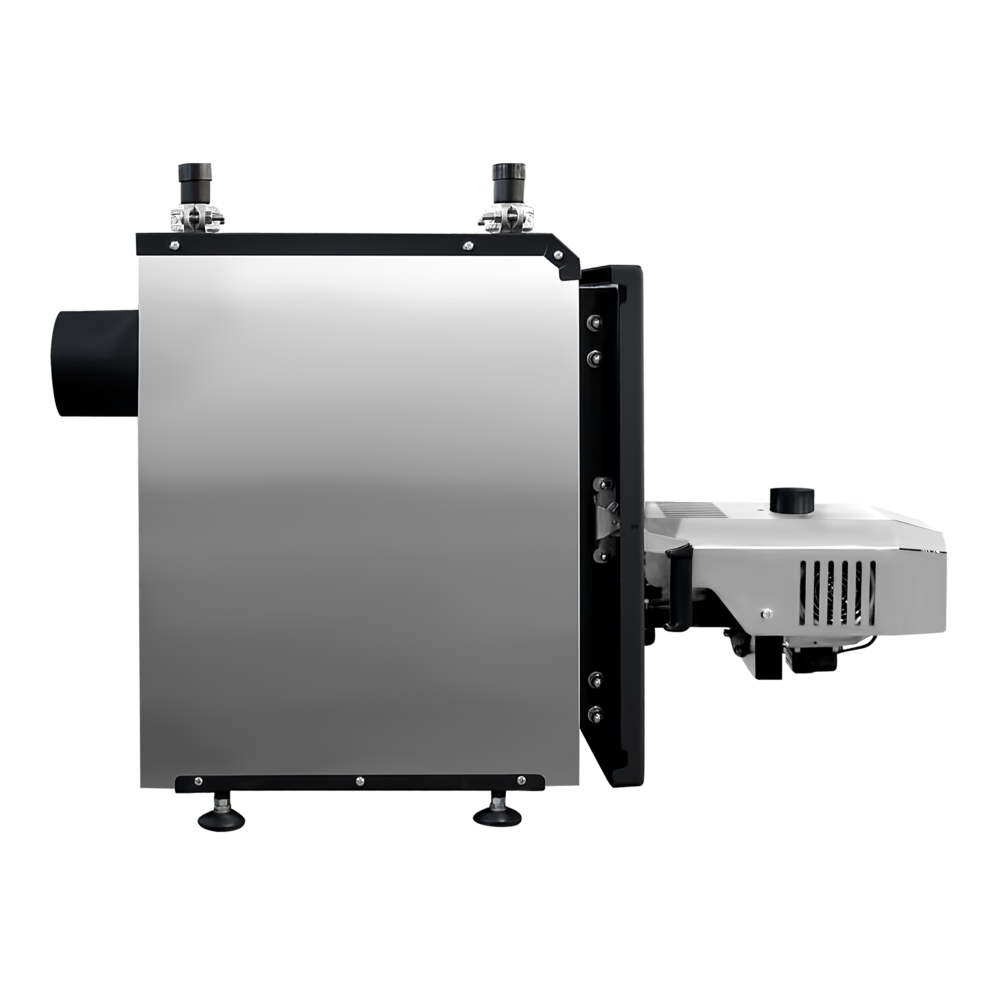

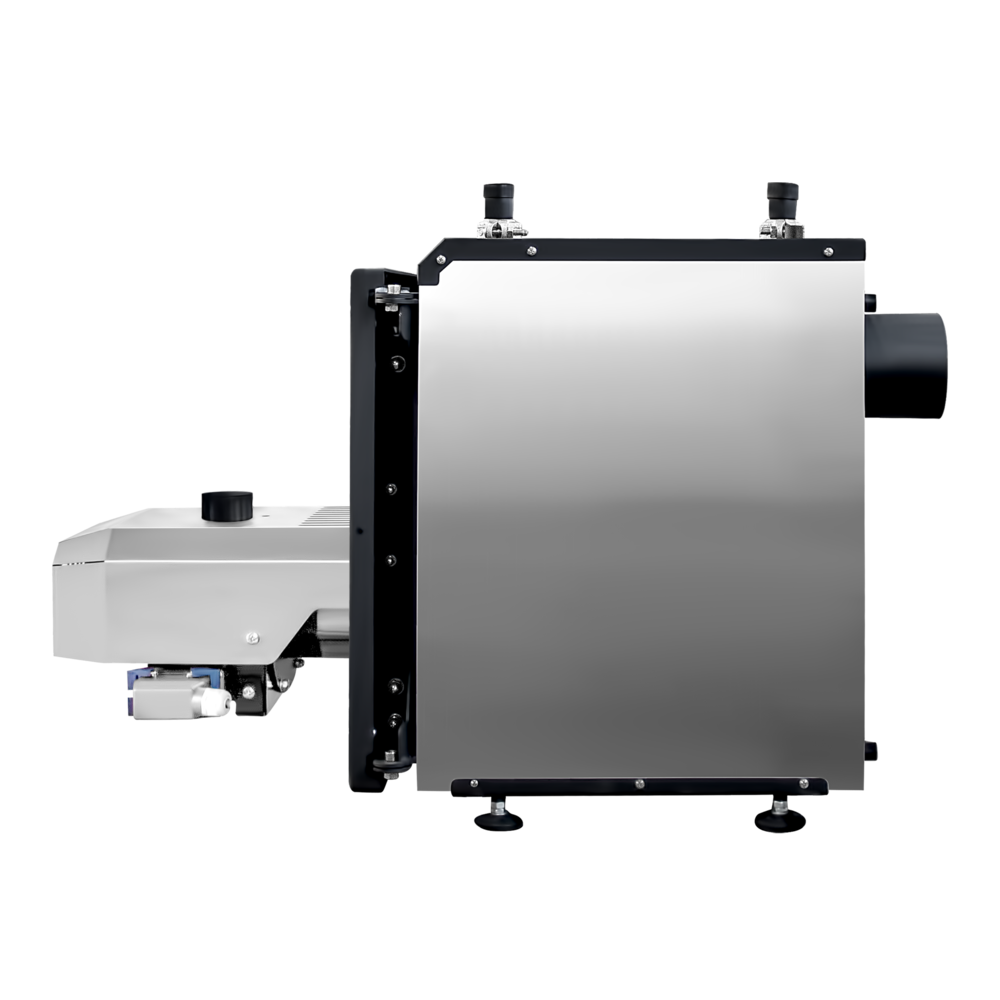

- Boiler casing: Made of AISI 201 stainless steel, polished for corrosion resistance and aesthetic appearance.

- Sectional door: A single door providing access for servicing the pellet burner, heat exchanger and for general inspection of the boiler. The possibility of adjusting the hinges and locks allows you to set a tight fit for the door.

- Flexibility of design: Possibility of changing the door opening side for ease of maintenance.

- Hybrid heat exchanger: Combination of plate and fire tube heat exchangers, which increases heat transfer efficiency.

- Big ash pan: Designed for several days of continuous operation at medium and high power, which reduces the need for frequent maintenance.

These features make the Mono-pellet 50 kW FOCUS pellet boiler reliable and easy to operate for long-term and stable operation.

A unique solution based on pellet burner FOCUS

The built-in pellet burner TM "FOCUS", which is included in this set of equipment, is capable of operating both on pure wood pellets and on agropellets with an ash content of up to 10%. Granules from sunflower waste, corn, buckwheat, rice, furniture waste and straw can be used as fuel without restrictions, which makes it universal and cost-effective.

The Mono-pellet 50 kW pellet boiler is an optimal solution for households, small shops and remote sites, thanks to the following advantages of the built-in burner:

- Automatic ignition provided by Japanese ceramic candles for contactless air ignition of pellets.

- A movable mono-grate that stirs the burning fuel and pushes high-ash residue into the ash pan, simplifying maintenance.

- Fuel feed auger that delivers pellets into the combustion chamber.

- Built-in burner auger temperature sensor, which ensures safety and prevents overheating by automatically shutting off the fuel supply in case of an accident.

- An infrared flame sensor that records the level of flame radiation to control its presence or absence, which ensures automatic regulation of the burner operation.

- Optimally selected proportions of primary and secondary air, which ensure efficient fuel combustion.

- The drive from the Swiss company "Belimo" with anti-jamming protection, which reliably moves the grate plate.

- Air-purged combustion chamber nozzle (for 100-150 kW models), which cools the nozzle and heats the secondary air, increasing efficiency due to gas afterburning.

- The nozzle and grate are made of stainless alloy, which increases their durability.

All models of flare burners are equipped with a fuel supply line "break" system, which guarantees safe operation. The controller allows you to easily adjust the operation of the equipment to achieve optimal performance. The Mono-pellet 50 kW pellet boiler is fully automatic equipment.

Functions and equipment

The automatic pellet boiler Mono-pellet 50 kW has a wide functionality and is suitable for various heating systems. Its power can be adjusted in the range from 5 to 55 kW, which makes it universal for different rooms. The heat exchanger surface area is 3.4 m², ensuring high heat transfer efficiency.

Functional:

- power adjustment within the range of 5 kW–55 kW;

- heat exchanger surface area 3.4m²

- 5 basic security levels;

- automatic operation: ignition, extinguishing, cleaning;

- ceramic lighter;

- low power consumption (excluding auto ignition - 40W) - can be powered by a battery and a solar panel;

- PID-regulation (the possibility of precise control of the burner using an analog control signal, including within the framework of "smart home" technology);

- movable grate for mechanical cleaning of the burner;

- pump control (hot water treatment and heating);

- work with room thermostat and internet module

- work with weather regulation.

Pellet boiler Mono-pellet 40 complies with GOST 32452-2013 (EN 15270:2007). A 12 month warranty is provided.

Contents of delivery:

- solid fuel pellet boiler Mono-pellet 50 kW in combination with a burner;

- screw conveyor 2 meters;

- corrugated PVC pipe - 1 m;

- pellet boiler controller;

- documentation.

Equipment for pellet boiler rooms

Devices and modules that increase the level of autonomy of the heating system:

- pellet hopper;

- room touch EcoSter regulator;

- additional temperature sensors.

Consult our specialists on the features of the deployment of heating circuits and connections.

Dimensions (edit)

Chimney outlet diameter

159 mm.

Requirements for the boiler room

When designing, you must adhere to the requirements:

- MDNAOP 0.001.26-96;

- DBN B.2.5-XX: 20XX;

- SNiP 2.04.05-91 "Heating, ventilation and air conditioning";

- SNiP II-35-76 "Boiler plants".

Interesting to read

Pellet burner operation process in detail

Which solid fuel boiler to buy for production

Reviews

There are no reviews yet.