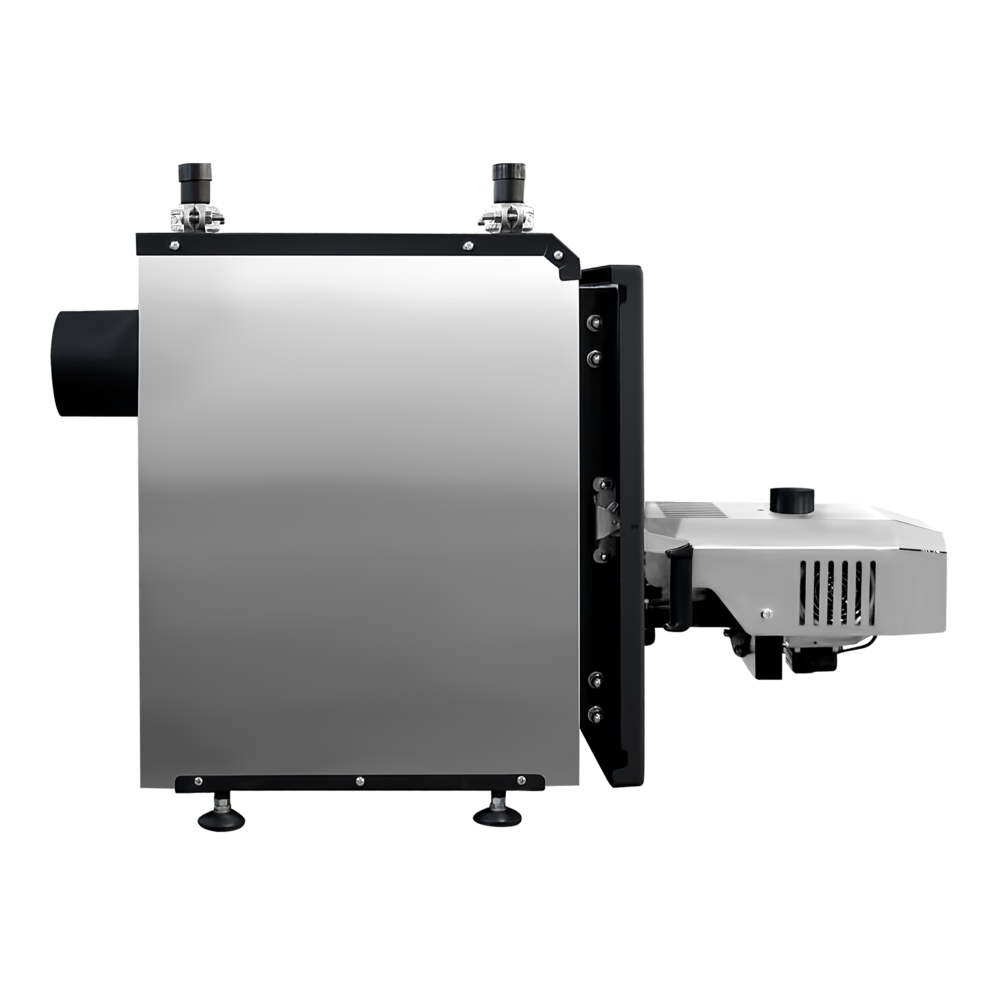

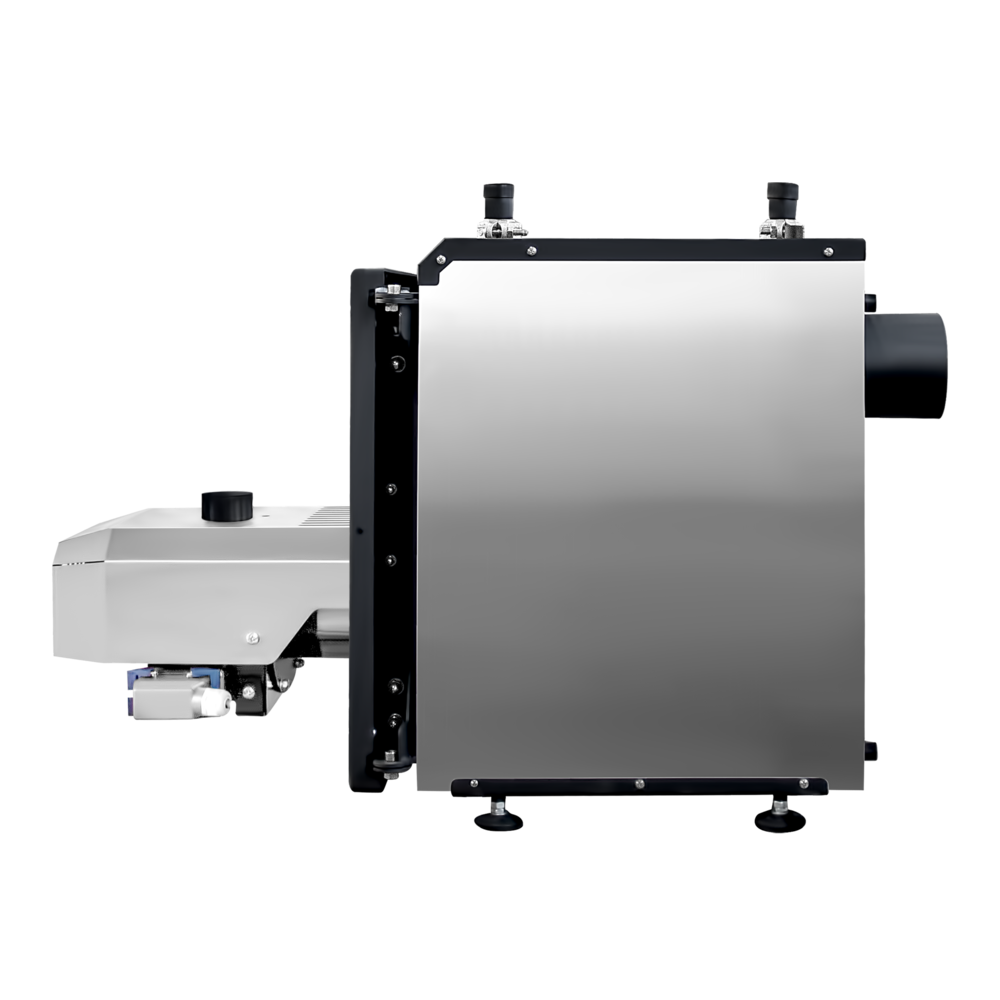

Automatic pellet boiler Mono-pellet 40 kW (5-45 pellet boiler Mono-pellet 40 kWkW) FOCUS

Modern and economical pellet boiler Mono-pellet 40 kW TM "FOCUS" is designed for household needs and small commercial premises, production facilities and workshops with an area of up to 400 m². With high-quality thermal insulation of the premises, its effective capacity allows heating up to 450 m². The boiler operates in a fully automatic mode, providing stable and efficient heating.

Special attention is paid to optimizing heat removal when using a pellet torch burner, which copes not only with clean wood pellets, but also with agropellets with a high ash content. Thanks to the grate self-cleaning function and automatic ignition, the system controls the flame using optical sensors, which makes the boiler operation simple and economical, allowing the use of commercially available fuel pellets.

The main advantages of FOCUS pellet boilers include an intuitive touch control panel with a user-friendly settings interface, convenient cleaning thanks to a movable grate that automatically removes ash, and precise flame control using an optical sensor.

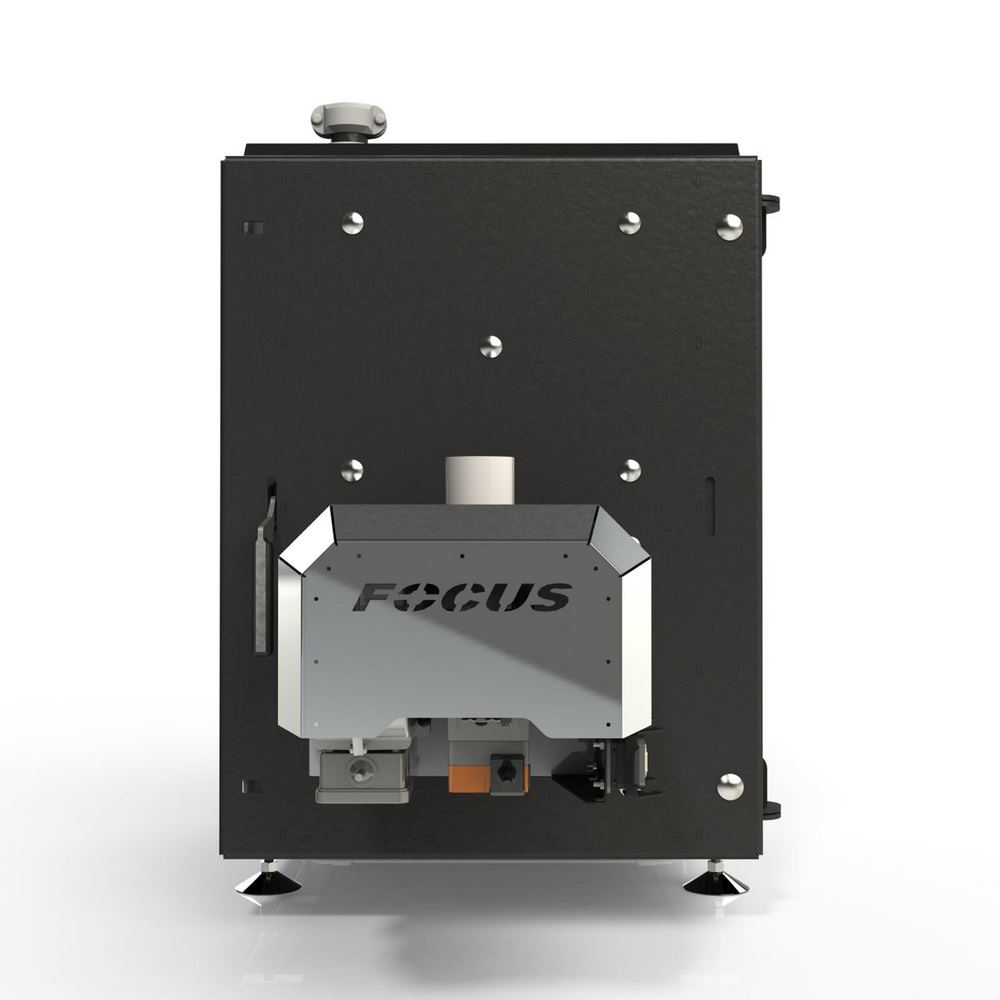

The Mono-pellet 40 kW pellet boiler has a highly efficient hybrid heat exchanger consisting of a plate and tubular part, which effectively removes thermal radiation from the burner torch. A large ash pan, specially designed for operation with high-ash fuel, and convenient access for servicing the heat exchanger make operation a simple process. The boiler design also includes an ash chamber in front of the chimney and a heat exchanger section for settling heavy particles. The ash pan is designed for long-term operation without frequent cleaning, especially when using an industrial series of boilers with high-ash pellets.

For connecting hot water supply, threaded pipes are provided, to which a heat exchanger or indirect heating boiler can be connected (an optional hot water temperature sensor is installed).

Boiler design features:

- Pellet boiler Mono-pellet 40 kW is made of structural steel 09G2S:

- thickness of the walls of the heat exchanger zone (furnace and primary heat exchanger, linings) – 6 mm;

- The thickness of the outer water jacket of the boiler is 4 mm.

- surface area of the heat exchange part (surface + fire-tube heat exchanger) — 3.4 m².

- Thermal insulation is made of basalt mineral wool 50 mm thick.

- The boiler casing is made of AISI201 stainless steel.

- The Mono-pellet 40 kW pellet boiler has one sectional door with an opening for the pellet burner, it provides access not only for servicing the burner itself, but also for servicing the heat exchanger, as well as general inspection.

- Adjustable hinges and locks for precise adjustment of the tight fit of the door to the opening simplify the initial installation and operation of the boiler.

- It is possible to change the direction of door opening depending on the installation location of the boiler.

- Hybrid plate and fire tube heat exchanger.

- Large ash pan designed for several days of continuous operation at medium and above average power.

Features of the operation of the complex based on pellet burner FOCUS

The Mono-pellet 40 kW pellet boiler has a built-in pellet burner TM "FOCUS", included in this equipment set, which ensures stable and efficient operation with KP 92% both on clean wood pellets and on agropellets with ash content up to 10%. The burner supports the use of fuel pellets from various wastes, such as sunflower, corn, buckwheat, rice, furniture waste and straw, which makes it universal for different types of fuel.

The Mono-pellet 40 kW pellet boiler is ideal for private households, small shops and remote sites.

Advantages of the built-in burner:

- Automatic ignition using Japanese ceramic candles, providing contactless ignition of pellets.

- A movable mono-grate that stirs the fuel and dumps ash residues into the ash pan.

- Auger for feeding fuel into the combustion chamber.

- Built-in auger temperature sensor prevents overheating and shuts off fuel supply in emergency situations.

- Infrared flame sensor for precise combustion control and operational safety.

- Optimal proportions of primary and secondary air supply for efficient fuel combustion.

- A reliable drive from the Swiss company "Belimo" controls the movement of the grate and is protected from jamming.

- Air-purged nozzle improves heat exchange and provides gas afterburning to increase efficiency.

All burners are equipped with a fuel line break for added safety, and the controller allows for easy boiler operation.

Functions and equipment

Functionality of the pellet boiler Mono-pellet 40 kW:

- power adjustment within 5 kW – 45 kW;

- heat exchanger surface area 3.4 m²;

- 5 basic security levels;

- automatic operation: ignition, extinguishing, cleaning;

- ceramic lighter;

- low power consumption (excluding auto ignition - 40W) - can be powered by a battery and a solar panel;

- PID-regulation (the possibility of precise control of the burner using an analog control signal, including within the framework of "smart home" technology);

- movable grate for mechanical cleaning of the burner;

- pump control (hot water treatment and heating);

- work with room thermostat and internet module;

- work with weather regulation.

Pellet boiler Mono-pellet 40 complies with GOST 32452-2013 (EN 15270:2007). A 12 month warranty is provided.

Contents of delivery:

- Solid fuel boiler Mono-pellet 40 kW in combination with a burner;

- Screw conveyor 2 meters;

- Corrugated PVC pipe - 1 m;

- pellet boiler controller;

- Documentation.

Equipment for pellet boiler rooms

Devices and modules that increase the level of autonomy of the heating system, as well as the necessary equipment:

- pellet hopper;

- room touch EcoSter regulator;

- additional temperature sensors.

Consult our specialists on the specifics of deploying heating circuits and connecting. The Mono-pellet 40 kW pellet boiler is a software-controlled equipment that allows for full control over heating circuits. This imposes certain requirements necessary to ensure efficient operation.

Dimensions (edit)

The diameter of the chimney outlet pipe is 159 mm.

Requirements for the boiler room

When designing, you must adhere to the requirements:

- MDNAOP 0.001.26-96;

- DBN B.2.5-XX: 20XX;

- SNiP 2.04.05-91 "Heating, ventilation and air conditioning";

- SNiP II-35-76 "Boiler plants".

Interesting to read

Pellet burner operation process in detail

Which solid fuel boiler to buy for production

Reviews

There are no reviews yet.