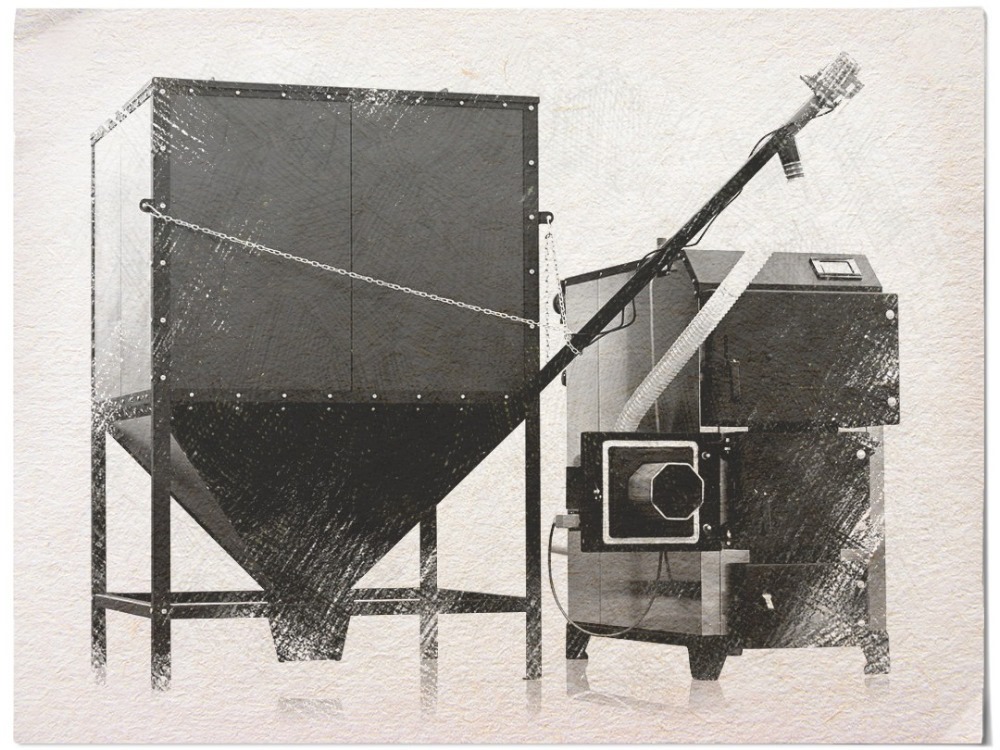

Economical burner heating with mechanical cleaning

Pellets are compressed crushed raw materials that generate heat when burned. Wood pellets, agropellets, lignin and peat granules are widely represented on our market. They are pressed in special domestic, semi-industrial and industrial grade press granulators. Like any solid fuel, pellets differ in calorie content, moisture content and ash content. The amount of heat released during combustion depends on the first characteristic, and the amount of pollution depends on moisture and ash content. It is to remove the latter that you need pellet burners with mechanical cleaning to provide a truly economical heating.

Many people think that glue is added to the pellets. But this is not the case, the pellets stick together during pressing under the influence of lignin, which is contained in the wood and has a high heat capacity. Pellets have low moisture content. High-quality granules have a moisture content of less than 5%.

For lower quality ones - 12-15%, but for firewood after drying chambers, the moisture index does not drop below 25%. At the same time, freshly sawn firewood has a record amount of moisture - up to 60%. As a result, pellets emit more useful heat than solid fuel, less polluting the boiler and the atmosphere.

Comparative characteristics of obtaining the same amount of heat with different types of fuel

| Pellet | Gas | Diesel | Firewood

with humidity no more than 20% |

Coal |

| 1000 kg | 553 m3 | 500 l | 1600 kg | 423 kg |

The benefits are clearly visible from this table. But approximately when using pellets, the costs for 50% are less than when heating with natural gas at pellet prices in 2020.

Why cleaning is so important for economical heating: pellet burners with mechanical cleaning

Any pellet burner can efficiently burn low-quality fuel, but it is not insured against the settling of combustion products on the walls of heating equipment. As the soot layer grows, it polymerizes and acts as a thermal insulator. For this reason, more pellets will have to be burned in the boiler to obtain the same amount of heat.

And the lower the quality of the fuel, the faster the owner of the pellet boiler room will face this effect. Accordingly, in order to provide economical heating with pellets, it is necessary to choose pellet burners with mechanical cleaning. If you are going to use low quality fuel, cleaning will be a regular activity for you. It is better to make it convenient to conduct it.

Approximately 20-30% the boiler loses efficiency with only 3-4 mm of soot. For this reason, cleaning and a cleaning device are a must on any selected model.

Cleaning types in solid fuel boilers

Three types of cleaning can be used in solid fuel boilers and burners:

- mechanical;

- pneumatic;

- pneumomechanical.

Mechanical cleaning is good because it is reliable and does not require additional equipment. In addition, it is carried out without ash scattering, and the medium remains constant.

The pneumatic cleaning method is carried out using a compressor. Ash blowing with air implies its scattering through the combustion chamber.

The pneumo-mechanical method involves the use of pneumatics to blow ash in the combustion chamber. The grates are cleaned mechanically. The variant combines the advantages of two cleaning methods with minimal ash blowing and maximum automation comfort.

Thus, the mechanical cleaning method remains the most reliable, even with the convenience of automatic pneumatic cleaning. These functional additions help to get rid of soot after long-term operation of a pellet burner with mechanical cleaning and guarantee a truly economical heating.