Heating of production facilities with climate control PLUM based on FOCUS boilers

Today we decided to look at industrial heating with PLUM climate control, which is installed on FOCUS pellet boilers. Despite the fact that many heating solutions have common features, the production format still has its own characteristics. It is worth immediately noting that FOCUS pellet boilers are represented mainly by an assortment of industrial models, the power of which is scalable up to 2.5 MW with a cascade connection. Thus, pellet boilers of this brand can become a worthy alternative for municipal and industrial boiler houses, and pellet steam generators can be used to generate electricity. But now we want to consider the option of climate control of industrial premises.

Workshop characteristics

Most often, production facilities are unheated hangars in which heat is supplied directly to the workplace. Obviously, preference is given to air heating. However, in practice, especially in older production facilities, preference is given to heating on water circuits and air heating of places where workers gather. This maintains a basic and comfortable temperature.

In food production, only air heating is usually used to avoid installing heating circuits. But our experts recommend heated floors and heated air ventilation in accordance with the climate control concept. As is known, climate systems imply mutually integrated services.

How to organize a workshop heating system

If the production does not have its own boiler room, then it is more profitable to equip one or more adjacent workshops with pellet heating boilers. The boiler room will not take up much space, and no significant maintenance is required other than loading pellets into the bunker. For maintenance-free boiler rooms we recommend self-cleaning boilers.

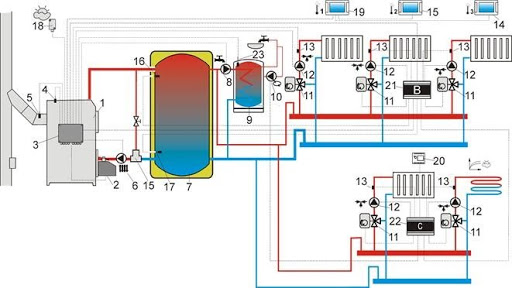

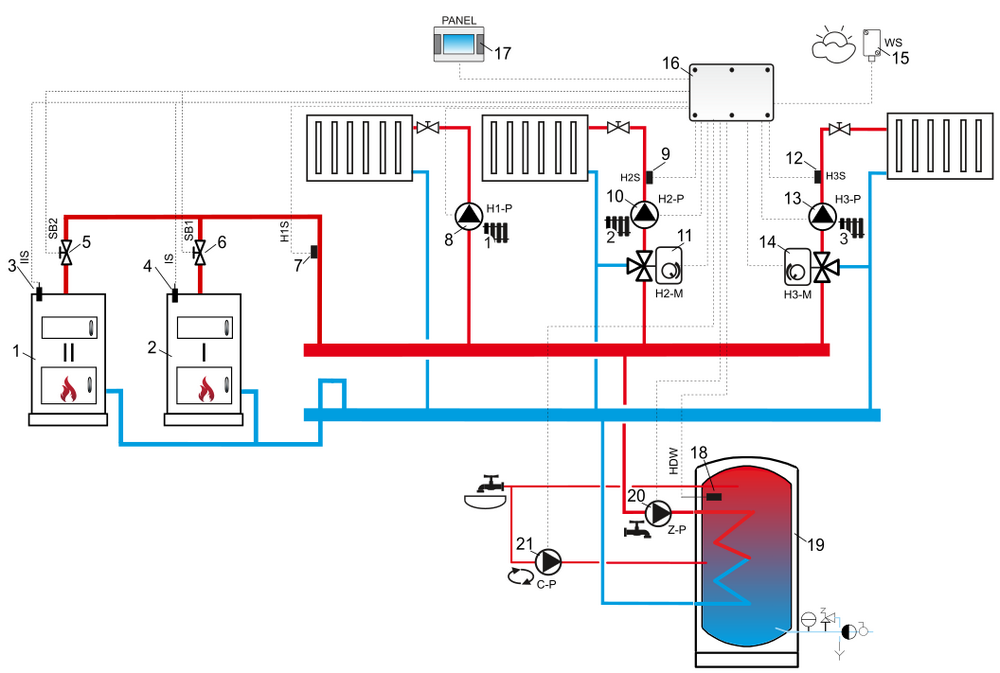

If you need to heat a multi-storey detached factory, we recommend cascading connection of boilers with multi-circuit hydraulic piping, separately controlled by climate control. For heating, it is better to use two types of heating: heated floors and air heating based on a water circuit, or water radiator heating and air heating with air recirculation from the ceiling to the floor.

We offer you several basic diagrams for these purposes. Our specialists can provide services for individual heating design for climate-controlled production facilities.

Organization of climate control in production

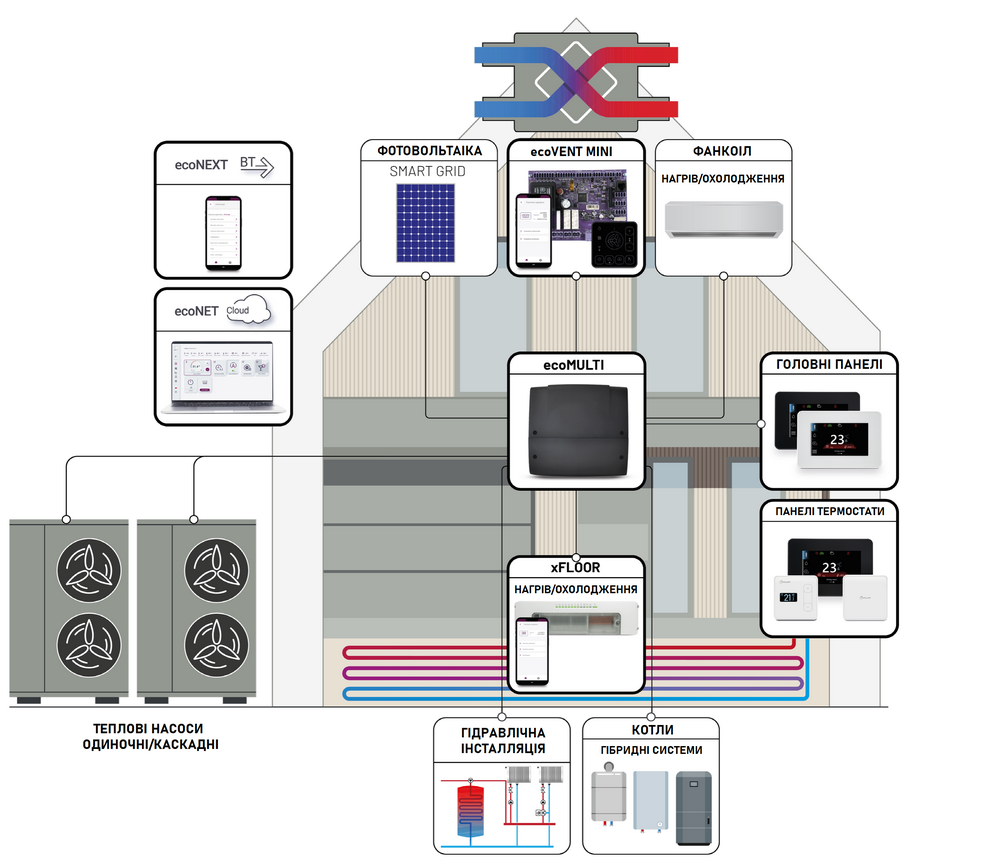

The principle of connecting smart automation to heating in production is the same for all models. Each pellet boiler has a built-in modified EcoMax microcontroller from the Polish company PLUM. On its basis, elementary weather regulation is organized by connecting sensors and controlling the speed of the pump and the intensity of the pellet burner flame.

If the system has several heating circuits or several boilers, they are served by climate control using an expansion. The system can be controlled on site using a touch panel, from a mobile phone and through the control system on the manufacturer’s website.

As terminal devices, for example thermostats, temperature sensors and Wi-Fi integrator, touch panel you can use the equipment in black case with wired and wireless connection.