The purpose of the presetting valves: how to equalize the temperature in the radiators

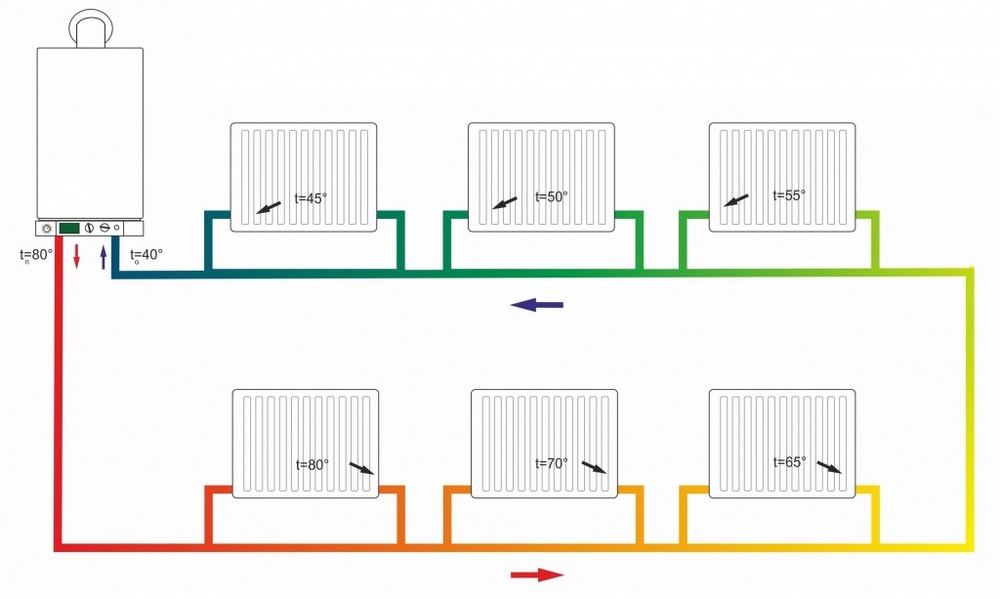

Many specialists, owners of private houses and even just residents of multi-apartment condominiums are well aware of the problem of different temperatures in radiators. The battery located at the extreme far point of the heating circuit is least heated. Moreover, this is typical not only for systems with a large number of consumers, but also for very "modest" branches for 3-5 radiators. Today we will look at how to equalize the temperature in radiators using preset valves.

Cold batteries are the scourge of an improperly designed heating system. By default, in heating systems, radiators will have different temperatures. it can only be leveled with the presetting valves.

If you encounter such a problem, then this indicates an insufficiently well-designed thermal scheme. Balancing and radiator type control valves allow you to equalize the temperature of the coolant on all radiators. And they fix the serious problems of many non-project heating schemes.

Control valves in the heating system

When it comes to control valves professionally, HERZ Armaturen should be mentioned. This company has been developing and manufacturing balancing valves for 120 years. The main task of such a valve is to ensure the design indicators of hot water consumption when passing through the heating circuit. Moreover, this can be done quite accurately.

The installation of such equipment is mandatory in heating systems with microclimate control. This is done, among other things, using thermostats. Otherwise, the climatic equipment will simply not work correctly.

If in an apartment building you see such a picture as shown in schematic diagram 1, then you can safely make claims to public utilities because of an incorrectly made project. In this regard, it must be understood that each heating system must provide the estimated consumption of the heat carrier in accordance with the developed documentation. This is realized in practice by analogue units for dynamic balancing or in statics, as well as when they are used together.

The most common is the static balancing of consumers of various types - from pipelines and heat exchangers to radiators, "warm floors" and other units.

Static balancing in thermal circuits

Preset balancing and radiator valves allow manual hydraulic adjustment depending on the nominal flow rate and the calculated pressure loss across the valve. This is the most common approach for equalizing the temperature of the heating medium in heating circuits. Dynamic valves involve connection to the control system and are more complex and expensive.

Each locking assembly can have its own characteristics. They are determined by the valve lift distance and are linked to the number of manual turns of the shut-off element from the closed position. The accuracy of the adjustment directly depends on the cost of such a control valve.

HERZ Strömax 4117

One of the most sought-after models on the market, which combines affordable price and high quality, is the HERZ Strömax 4117 valve.

Its features include:

- accuracy - 0.25 turnover of the shut-off element;

- setting porch (implemented by the bushing);

- there is no protection against re-adjustment;

- visualization of values in 4-turn increments, located on the spindle shank.

HERZ Strömax 4117 is recommended for domestic heating systems.

HERZ Strömax 4017

The HERZ Strömax 4017 valve belongs to the more expensive price segment and allows more precise settings:

- with an accuracy of 0.1 turn of the flywheel;

- there is a bridging position with a bushing;

- to protect against changes, it is possible to install a seal;

- visualization of the adjustment accuracy is in a special window of the shut-off element;

- there is a measuring diaphragm for digital data acquisition when a special computer device is connected.

The model is distinguished by a non-rising spindle, which is often found in such valves. As a result, the valve can be mounted in a small space.

This kind of valve is obviously used in public utility systems. It allows you to digitally capture data. This is usually required during repair work when the actual flow rate does not correspond to the design one. Also, the computer connection is used for "manual" hydraulic balancing when design values are not available. For this purpose, a proportional method is used by entering values into a measuring computer.

Models from other manufacturers

The consumer can choose valves from other manufacturers, but it must be borne in mind that different models have different hydraulic characteristics. When replacing models with others, recalculation is carried out in accordance with the new values.

The mentioned valves can be selected in the HERZ STRÖMAX-R app for mobile devices, you only need to know the flow rate and the pressure drop across the valve.

Radiator valves

Radiator valves are also a control valve. With their help, you can set the necessary indicators for adjusting the battery by selecting the same temperature on the final room heat sources.

Adjustment of the analog valve of the HERZ TS-90-V series is achieved by changing the position of the sleeve inside the valve. When the handwheel rotates in the valve box, the lifting height of the control core above the valve seat changes when it is fully closed.

One of the interesting features of thermostatic valves is the hidden presetting. It consists in changing the hydraulic resistance by means of an adjustable cylinder covering the spool with throttling holes of different diameters.

HERZ valves are very easy to service engineering objects. Housings and crane axle boxes have the same dimensions. As a result, you can replace the axle box and put another one (and without draining the system using the HERZ key). At the same time, the hydraulic characteristics change, and hence the control features of the valve.

How to equalize the temperature in radiators using different presetting valves

Manual radiator valves are in high demand due to their low cost. However, their use does not allow making more precise settings. The lack of a thermal head in the radiator valves results in higher heating costs.

At the same time, manual valves allow you to perform a hidden presetting, which allows you to balance the distribution of the coolant between the heating devices. Subsequently, it is possible to control, in general, the temperature of the heating circuit through the main complex, by regulating the speed of movement of the coolant and the circulation pump.

Pros of manual radiator valves:

The presence of a hidden preset.

Disadvantages:

- when the user closes the circuit, which is possible, without an emergency bypass for the coolant, an emergency situation is inevitable;

- rise in heating costs due to the lack of thermostatic regulation;

- the need for an exact number of radiators to heat a certain living area with the same characteristics of the insulation of the building walls and the thermal conductivity of the windows.

The disadvantage of installing a radiator valve with manual adjustment is the possibility of shutting off the flow of the coolant by the user, which will lead to an inevitable emergency. In this case, if there is no backup path in the heating circuit, presetting control valves are recommended. They solve the problem of balanced delivery of coolant to radiator devices. However, this requires design values or fitting adjustments.

Pros of using presetting valves:

- high accuracy of adjustment and balancing of final heating devices for heat output;

- exclusion of the possibility of emergency situations with complete overlap of the circuit;

Disadvantages:

- the need for design values;

- complex adjustment by the selection method.

An alternative is thermostatic valves with Wi-Fi regulation, which, for example, are part of the equipment line Plum Ecomax. IN solid fuel boilers FOCUS and pellet burners of this brand, the management is carried out using a set of equipment. This solution avoids the effect of uneven heating of the batteries, which is shown at the beginning of the article. And in fact, he offers an alternative how to equalize the temperature in the radiators.

With the advantages of a line of equipment Plum Ecomax, can be found additionally.

In Plum Ecomax, the radiator control valves operate on a thermostatic principle and are controlled via a touch panel. Accordingly, the user cannot manually shut off the heating medium flow. That is also a constructive protection against accidents possible when using manual valves. The presetting takes into account the design measurement characteristics of the system. At the same time, savings on heating are guaranteed.

Buy ready-made hydraulic piping kits

Order a project of a household boiler room

Get a project with a climate control system (paid)

Order a project with automation of coolant supply