Automated boiler room for pellet production

Automated boiler rooms for industrial facilities are specially designed heating systems that provide a high degree of automation and process control. What features should an automated boiler room for production have?

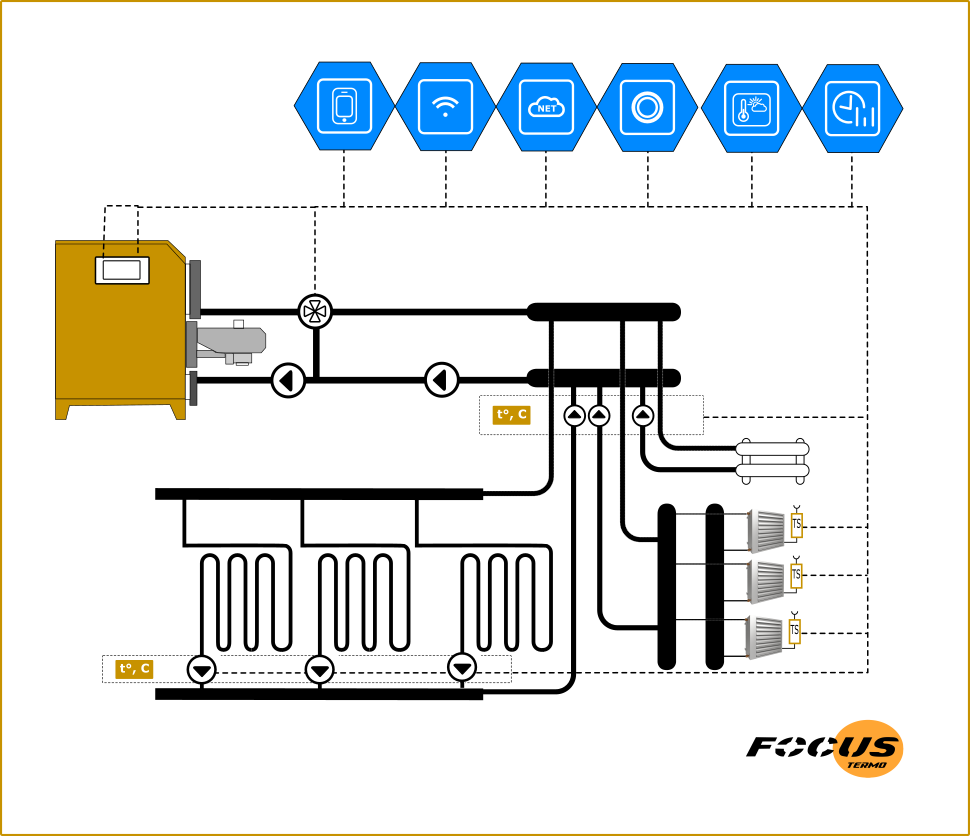

First of all, we are talking about heating large rooms with significant heat losses. For this reason, the choice of boiler equipment is focused on air heating and powerful heat sources, which are complemented by a system for recirculating air masses from the ceiling to the floor of the room. In workshops, workplaces are also heated using heated floors, radiators and convectors with fans. What are the automation tools for such solutions?

Industrial automatic boiler room

When choosing boiler equipment for production, preference is given to models with maximum automation. Although more expensive to install, it is beneficial as the business can commit to a fairly large budget and operating and maintenance costs are dramatically reduced. For this reason, from our range for organizing a heating circuit, we recommend self-cleaning boilers with ash removal and pneumatic cleaning. Additional automation makes such equipment virtually maintenance-free.

If we are talking about a separate room, then you can purchase boiler hopper for large volume pellets. Depending on the needs and organization of pneumatic feed by auger. It should be noted that screws for supplying fuel pellets in production are made according to a separate project.

The deployment of a boiler circuit will also be required; it will depend on the type of production and the nature of the workshops. In general, we will talk about air heating. If it is the only one, then it is more profitable to purchase pellet steam generator, which will provide electricity and a large amount of heat and on its basis build a factory thermal power plant.

Climate control devices will also be required, but their choice will also differ depending on the specific project.

How does an automated boiler room work?

Currently, industrial boiler houses (including modular) are automated by default and include the following subsystems and components:

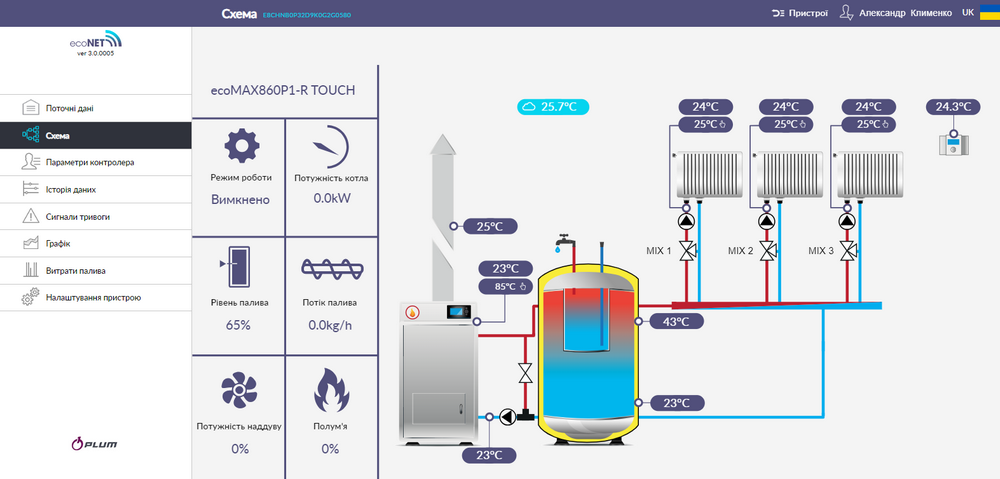

- Control and monitoring systems: Automated boiler rooms are usually equipped with modern control and monitoring systems that allow you to control and regulate the operation of boilers, pumps, distribution units and other components of the heating system.

- Operation optimization: Automation systems make it possible to optimize the operation of a boiler room in accordance with changing loads and production needs. They can automatically regulate boiler power, coolant supply temperature and other parameters to ensure efficient operation of the heating system.

- Backup and emergency modes: Automated boiler rooms can be equipped with backup and emergency systems that ensure reliable operation of the heating system in the event of emergency situations or failure of main equipment.

- Remote control and monitoring: Some automation systems allow you to remotely manage and monitor the operation of the boiler room via the Internet or mobile applications. This provides the ability to monitor and control the heating system in real time from anywhere in the world.

- Energy efficiency: Automated boiler rooms can be designed with energy efficiency and energy optimization in mind. They can automatically adapt to changes in environmental conditions and production needs, reducing energy costs and increasing the overall efficiency of the heating system.

These systems can be equipped with various additional functions and capabilities depending on the requirements and needs of a particular production. They provide reliable and efficient heat supply for production facilities, saving time, resources and reducing the likelihood of downtime and emergency situations.