Organization of temperature control in systems with two boilers

PLUM automation, with the help of which climate control is organized in systems with two boilers, involves connecting a backup boiler using an expansion module. Today we will look at how you can connect additional boilers to any model of FOCUS pellet boilers and deploy climate control.

When is this required? Of course, you need to take into account that any pellet boiler is still a solid fuel boiler, which can simply be left without fuel. This is a disadvantage compared to gas heating, but it can be leveled out using any type of boiler if it is connected as a backup. Another reason for connecting a backup boiler is cleaning and maintenance; not in all cases it is possible to purchase a self-cleaning boiler and ensure continuous operation of the device. This solution is suitable for greenhouses, where we discussed climate control last time.

How to connect a backup boiler to a FOCUS pellet boiler

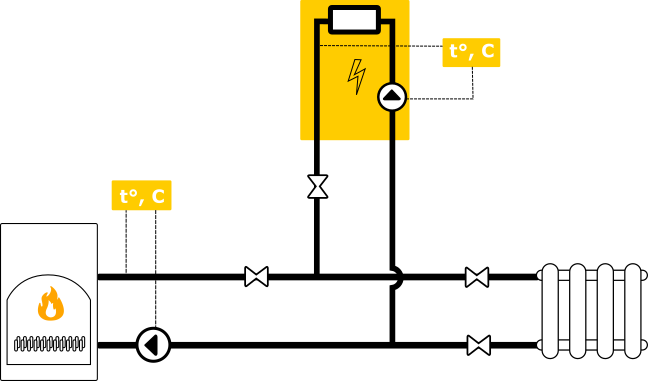

Each FOCUS pellet boiler has a built-in microcontroller that controls the operation of the pellet burner. To connect the backup boiler to the burner microcontroller, you need to connect PLUM expansion modules and the necessary equipment to organize an additional heating circuit. The boiler can be connected when the main boiler does not maintain the temperature set on the control panel. This could be, for example, an electric boiler or a more expensive diesel boiler that will help solve the problem.

This is appropriate if, for example, the house is located in the city center and is inhabited by retirees who are not always able to load pellets. Also, the option of a backup boiler is necessary for greenhouses if there are interruptions in the supply of pellets and service maintenance is required. Either way, a backup boiler will improve your home's safety levels.

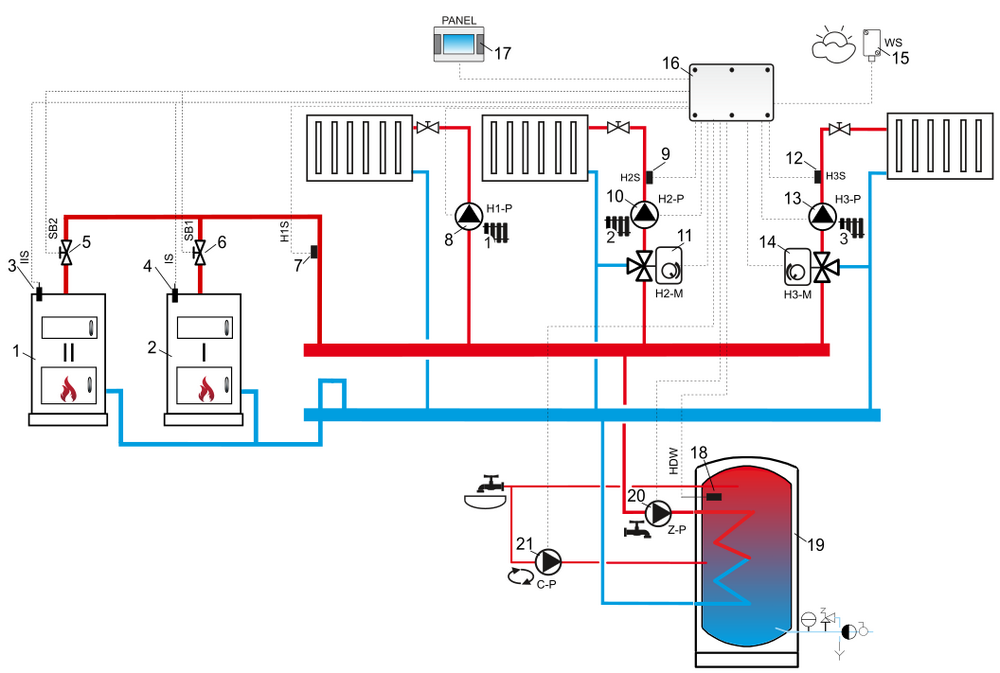

But the expansion module can serve not only heating circuits with backup boilers, but also expand the heating system as a whole, as shown in the hydraulic isolation diagram.

Cascade connection of boilers

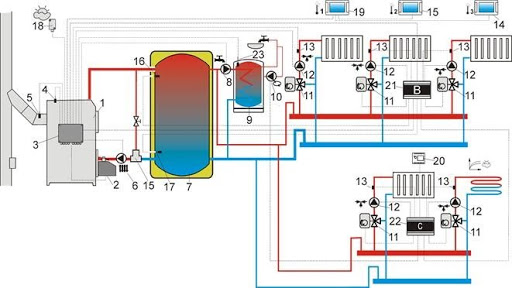

Another option for continuous heating is to install boilers in a cascade and, accordingly, cascade connection of equipment. This option is acceptable if the heating power can be increased and the connection of additional boilers is required. If some units can be turned off due to the operation of others. This boiler room option will be convenient for utilities and industries where climate control in systems with two boilers is not a sufficient solution.

Cascade boiler controller with touch control, regulates up to 7 heating circuits.

Cascade boiler controller with touch control, regulates up to 7 heating circuits.