We are deploying a mini-CHP on pellets with TM FOCUS equipment

At the moment, the localization of CHP is the optimal heat and energy demand. Moreover, the proposed equipment - mini-CHP on pellets - can be successfully used in peacetime for heating and power supply of villages, farms, hospitals, schools and administrative buildings in rural areas. It will be useful for rural communities to learn about the new opportunity to provide themselves with autonomous heat and electricity with low maintenance costs.

You can completely get rid of dependence on central heating networks, electricity supply and gas pipelines by switching to an autonomous pellet technology for generating heat and electricity using FOCUS TM equipment.

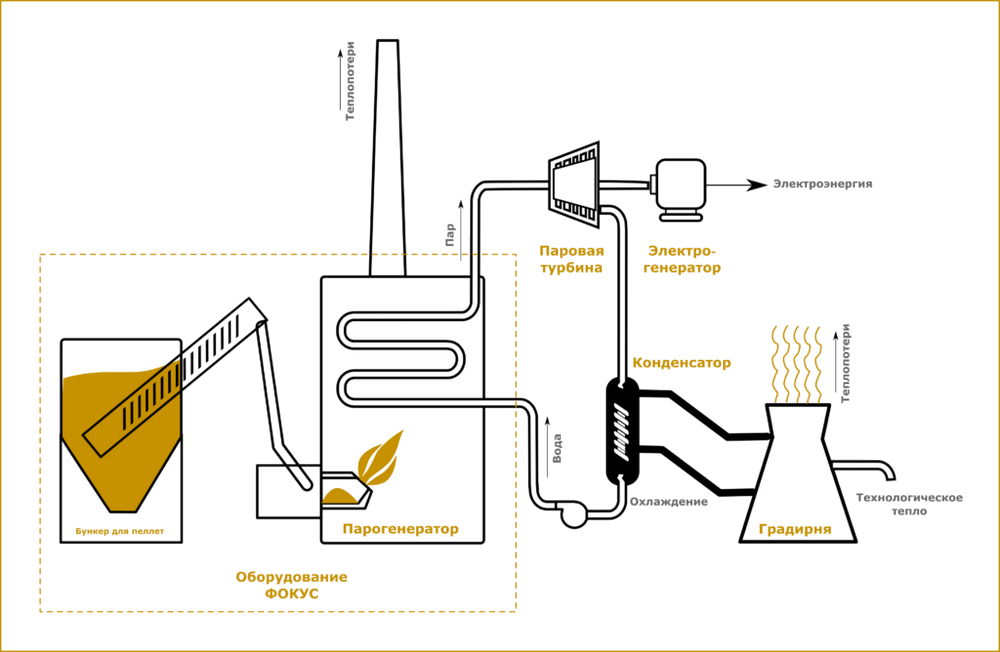

The principle of organizing a mini-CHP on pellets

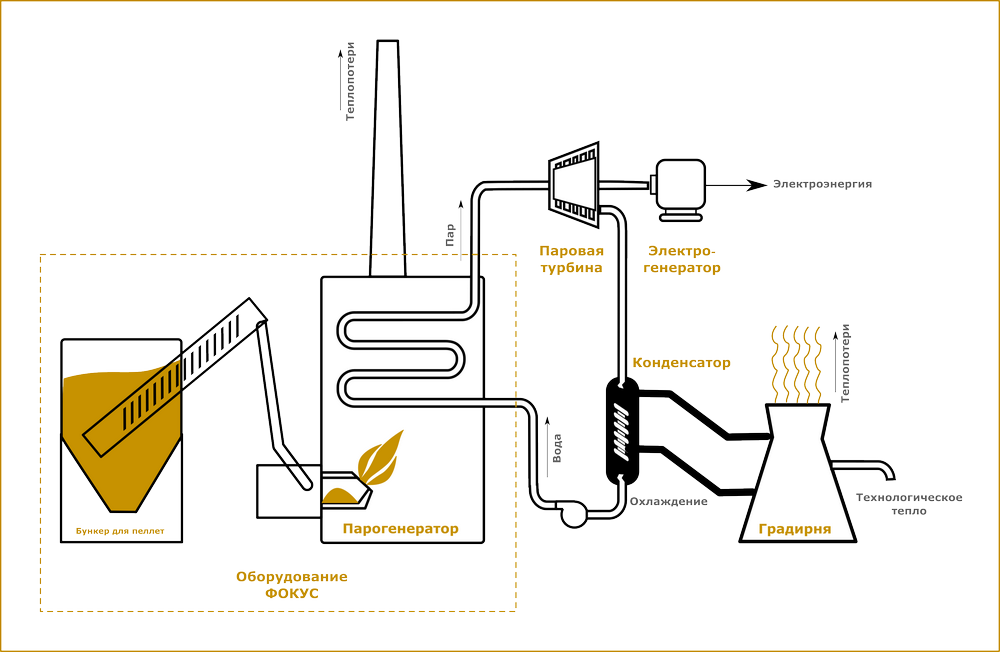

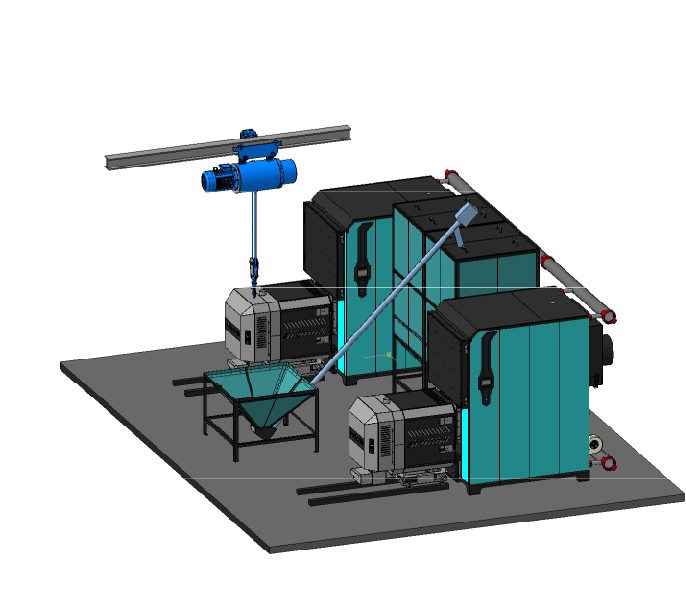

The proposed mini-CHP on pellets is based on the equipment of TM "FOCUS" and third-party manufacturers. This is about pellet steam generator FOCUS and turbine generator set another Ukrainian manufacturer that generates electricity with the participation of steam. These main units of CHP provide heat supply to consumers and electricity generation. Heat can be supplied from two sources - from the hot water recovery unit obtained during the operation of the microturbine, to the direct production of hot water using a steam coolant. The circuit diagram is shown in the figure.

Microturbines in the production cycle of heat and electricity complement the FOCUS steam generators, which have a steam productivity of 2.5 tons of steam per hour, and allow such installations, in combination with a turbogenerator module, to be converted into a mini-CHP on pellets with an electric power of 250-10,000 kW.

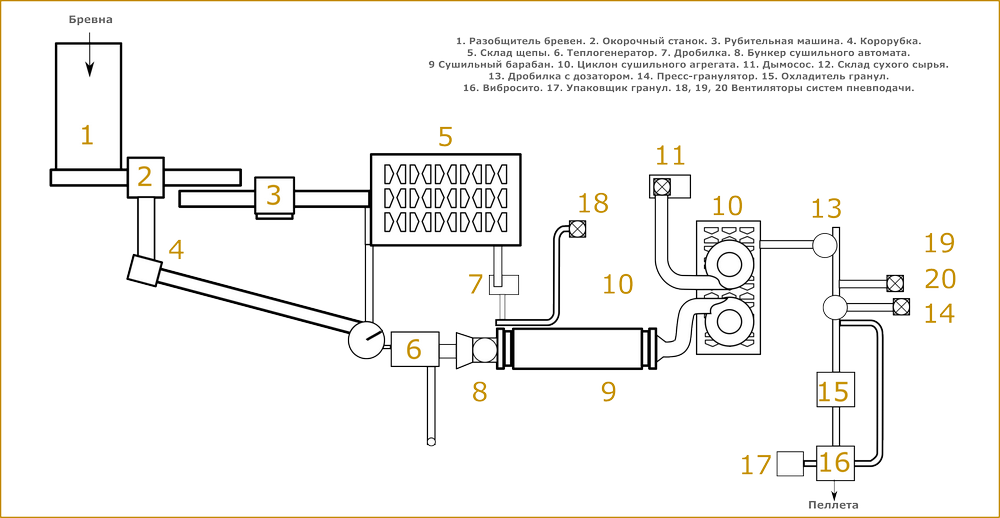

Fuel wood pellet production line

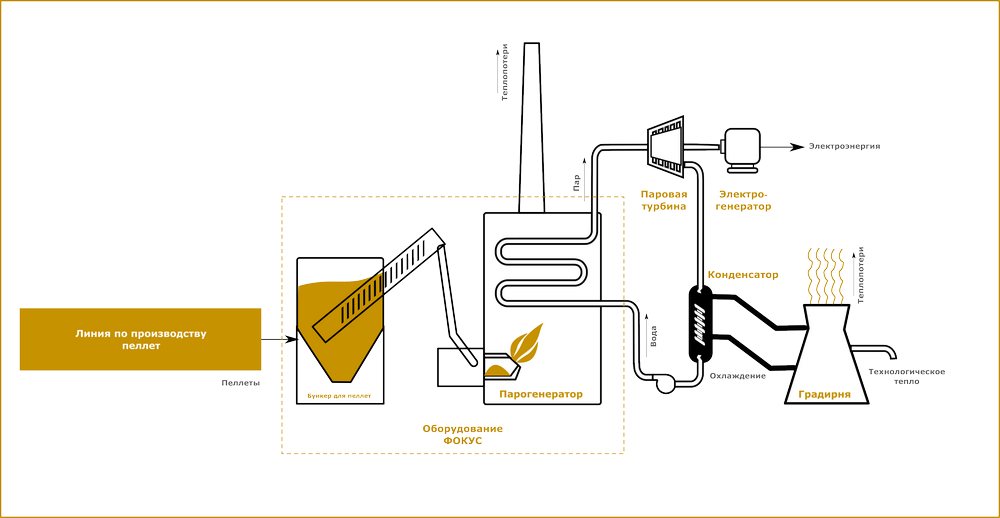

Mini-CHP with steam generator

The proposed equipment can be functionally combined with a line for the production of wood pellets and agricultural waste, including hay and other raw materials. These production lines are installed in a full-cycle pellet line - from pellet production to electricity generation and heat recovery for heating.

Autonomous heating and power supply with minimal costs is fully consistent with the sustainable development model and provides for the needs of the population and the disposal of organic waste, taking into account that these purposes do not require sources of non-renewable fuel.

Waste heat for rural schools, hospitals and administrative buildings

In addition to the primary heat, which is obtained during the operation of the pellet steam generator and steam used as an effective heat carrier, there is also a secondary heating of water during the cooling of the microturbine. This water can be directed to an urban or rural heating system to serve critical infrastructure. On the one hand, a mini-CHP on pellets works on pellets, which can be made from agricultural waste, on the other hand, it effectively uses the utilized hot water from the turbogenerator.

Schematic diagram of the CHP operation on the FOCUS steam generator

Pellet production line

The best option to reduce costs to zero is the production of pellets at the point of use. This is due, on the one hand, to the need to reduce the cost of production, on the other hand, to the disposal of organic waste, which is available in abundance after the autumn harvest. The only drawback of this concept is the removal from nature of humus, which is obtained during the winter from agricultural waste and is naturally used to form the soil layer. Surplus pellets can be sold to the population and residents of the village who have purchased pellet boilers.

Straw pellet production line

Example: 1 MW pellet boiler plant with automatic big bag unpacking

You can implement the production of fuel pellets in a handicraft way using a granulator, which is shown in the video. They are manufactured by Tekhnomashstroy, they are offered in two versions of models: granulator GRAND and granulator PELLETNIK. You can also purchase a production line for making hay pellets, which is shown in another video.

Advantages of pellet plants

TM "FOCUS" offers well-designed heating equipment that runs on pellets. Combined with steam generators, the devices can generate and store electricity and provide heat to critical rural infrastructure. Contact us for the design of a full cycle boiler house, including a heating unit, power supply and a pellet production line.

Pellet lines generating heat and electricity are the way to autonomy and independence. Moreover, you can reduce the cost of heat and electricity to almost zero by using agricultural waste for the manufacture of pellets.