Where the high efficiency of boilers is laid down - what to look for when buying heating equipment

The traditionally high efficiency of boilers is the subject of advertising not only for the selected heating technology, but also for a specific model offered by the manufacturer. In our case pellet burners FOCUS have efficiency 95%. It is due to low losses and really intense heat transfer, thanks to the use of a physical process and the creation of conditions for it. This is volumetric combustion.

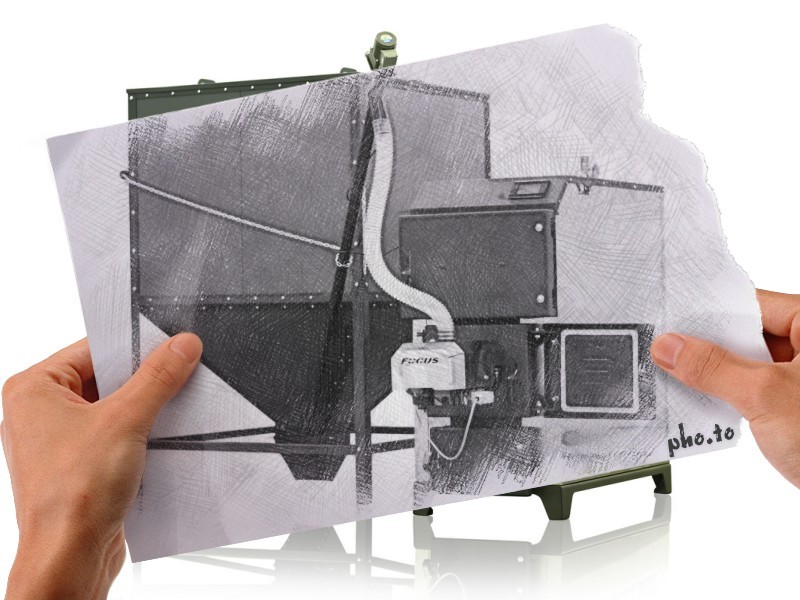

As in modern boilers using the condensing principle of heat extraction during combustion, our pellet burner FOCUS provides for pyrolysis afterburning of fuel, which significantly increases efficiency. Like a pellet boiler, the burner must provide a full range of functions if purchased as a separate module.

Why efficiency solid fuel boilers pretty low?

The high efficiency of solid fuel boilers is characteristic only of pellet and pyrolysis models. The maximum heat extraction in this heating equipment is due to the technology used:

- in modern pellet boilers, volumetric combustion is used, characterized by intense heat transfer and complete combustion of the fuel;

- in pyrolysis boilers, the primary fuel is only a source of flue gases, which are burned with a high heat capacity already in the second chamber. In this case, the primary fuel should only smolder, and not heat the heat exchanger.

It is obvious that in pellet boilers or burners, even with an ideal volumetric combustion process, combustion gases are still generated. They can simply be released into the chimney, or you can try to burn them, gaining additional heat. This physical process is called pyrolysis afterburning.

Obviously, in solid fuel boilers, volumetric combustion, which occurs immediately in the entire volume of fuel, is not realized. In this case, a large amount of combustion products are released, from which, if heat is taken away, then an insignificant part. The ignition of carbon monoxide in the chimney is not only an undesirable consequence, but also extremely unsafe. For these reasons, the efficiency of solid fuel boilers ranges from 75-90%. But it can be increased, for example, due to a point supply of air through nozzles that simulate volumetric combustion.

What can reduce efficiency?

Heat exchanger. Even with an excellent flare burner that implements an ideal physical process of volumetric combustion with high heat transfer and complete combustion of flue gases, the boiler efficiency can be reduced. This is possible due to the insufficient surface of the heat exchanger, poor heat extraction and a number of other characteristics. A heat exchanger is a qualitative characteristic of efficiency that affects its quantitative indicators.

Soot

A high percentage of ash and moisture content significantly increases the intensity of soot sludge on the walls of the boiler room. It is deposited not only on the elements of the pellet burner, but also on the structure of the heat exchanger. As a result, the soot performs the tasks of a heat insulator, not allowing heat to pass through.

It is worth noting that even automatic cleaning pellet golreki will give nothing without cleaning the boiler itself.

What to look for when buying a boiler or burner

How to choose a boiler is a rhetorical question asked by many, but often not finding a capacious answer. The thing is that the selection is carried out according to the individual characteristics of not only the object, but also taking into account the selected technology. Therefore, the question must be considered in every practical case.

But there are also universal tips on what to look for:

- to the technological level of the selected model. The more technologies to improve efficiency, the more realistic the manufacturer's promises;

- on the heat exchanger and the area of the heat exchange surface;

- for the availability of methods for cleaning the boiler.

Of course, in each price category, the best models in their class are presented, showing high boiler efficiency. It is specific models that are ideal for a certain circle of buyers of a boiler or burner.