Automation of the heating and hot water supply system of a single-family house with an individual boiler generator

Our publications have repeatedly raised the topic of using Smart Home technology and climate control in deployed heating systems. At the same time, general principles and approaches were stated, but specific thermal schemes were not considered. Considering the peculiarities of our production, that, for example, solid fuel boilers FOCUS equipped with a microcontroller from the equipment family Plum EcoMAX, we continue to acquaint readers with new solutions. After we have considered building heating system automation schemes, it's time to show how this would be done using the example of a single-family house.

At present, it is possible to automate the operation of even a solid fuel boiler or furnace. The only thing is that this issue is implemented with the help of a buffer tank that accumulates heat. However, in pellet boilers, this option is redundant and is used only for the secondary heating boiler for domestic hot water.

For owners of frame houses who want to install an air heating system according to the Canadian method, the automation of the ventilation system will be of interest. One boiler generator of diesel or gas type is considered as a heat source.

The proposed scheme can be expanded. First of all, reserve boilers have been added, operating on a different type of fuel for full autonomy. Using solid fuel boilers FOCUS as a contgenerator, the automation task is somewhat simplified. However, the system must have the necessary adjustments. They will be discussed in the publication.

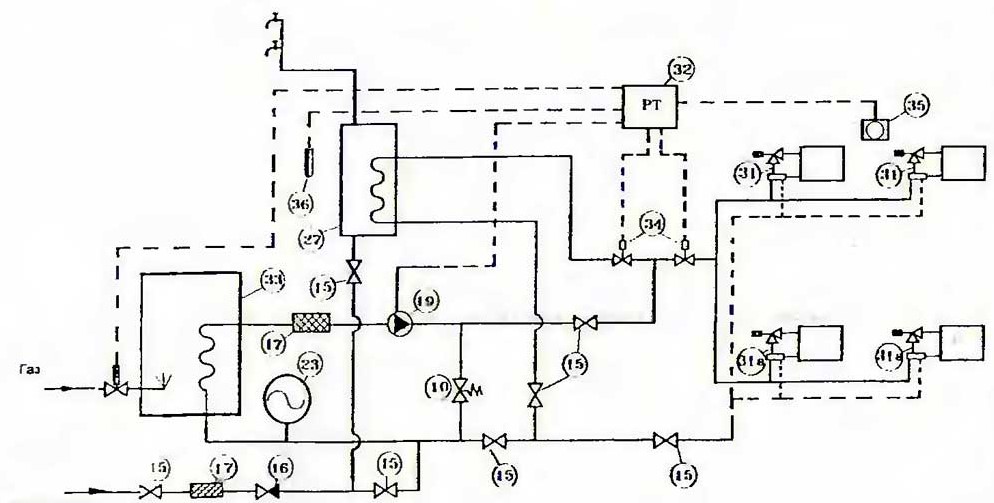

Heating automation scheme with underfloor piping

We are used to pipe fittings running along walls. External installation is carried out in order to increase heat transfer and heat the circuit of the house with high quality. The underfloor lining is borrowed from foreign practice, to some extent it resembles a "warm floor". And also requires floor insulation or thermal insulation of pipelines. This will not only allow you to heat the floor with available means, but also protect the pipes from freezing. In normal practice, they are not laid in this way. The automation scheme and its work has its own specifics, which is reflected in the design decisions.

Distribution pipelines are equipped with underground radiators. The result is the impression of air heating in the house, although the solution does not differ at all from the traditional one.

A gas or diesel boiler acts as a heat source. The equipment can be replaced with something else. Including a furnace with a heat exchange circuit. However, in this case, it is necessary to take into account the features of the heat generator, which may affect the final automation scheme of the boiler room.

The boiler is insulated in a separate circuit

The boiler is connected to a separate circuit with a circulation pump, an expansion tank and a bypass valve, which guarantees stable performance during the operation of the devices and pumping the coolant. In practice, the listed equipment is available in the system of gas boilers, so the equipment can be installed without additional equipment.

At the same time, to regulate the parameters of the operating mode of the heating system and hot water supply, it is necessary to install a control system in which there is a programmer. The advantages of such a solution can become tangible not only when automating heating with one heat source, but also when connecting several boilers and sensors.

Programmer functions

In the proposed scheme, the programmer controls the water supply to the heating system and the DHW tank to the heat exchanger. In this case, the valves of the electric drive are switched. In the case of double-circuit boilers, the indirect heating tank for hot water supply can be safely abandoned. The programmer receives data from room thermostats, saved user scenarios and temperature sensors in the circuit, indoors and outdoors.

Indirect heating boiler for domestic hot water

In the proposed scheme, the indirect heating boiler is replenished with hot coolant 4 times a day. The room temperature changes with changes in temperature. If there is no need for heat supply, the heating equipment is turned off. The automation scheme is responsible for this.

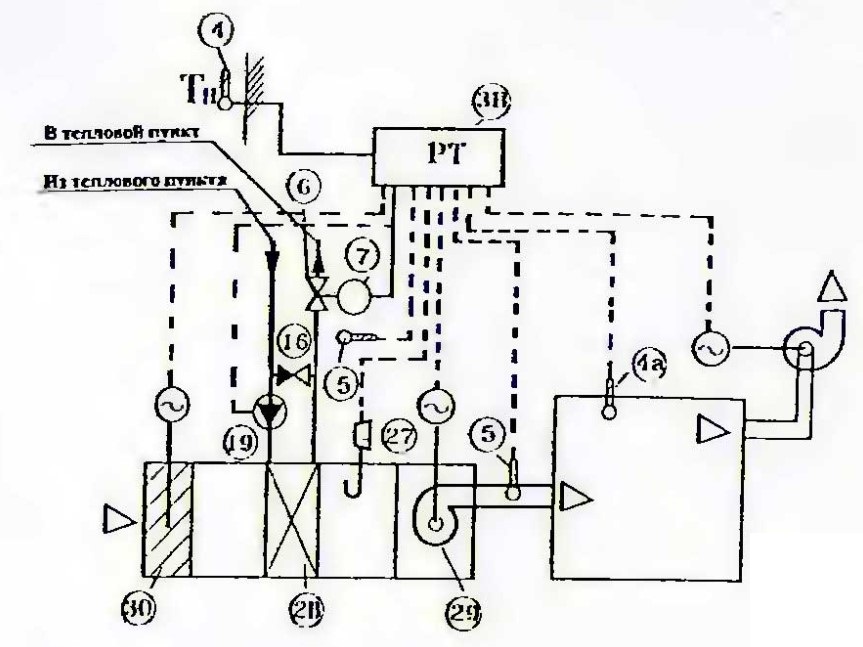

Ventilation installation diagram with pre-balancing valves

In the ventilation duct, in order to heat the air from hot water in the system, specific pre-set valves are used.

The proposed automation scheme will help solve the following heating problems:

- control the fan motor and the street air intake damper electric drive;

- regulate air heating by using an automated outside air supply damper;

- provide heating of heaters and protection in winter;

- start and stop functions;

- programmed control according to scenarios and climatic parameters.

These functions are usually assigned to a special electronic regulator. It works according to the following principle:

- At start-up, the control system turns on the heater, then the ventilation device.

- The temperature of the coolant changes with the participation of the resistance of the temperature sensor.

- Further, the regulator maintains a constant temperature in the room due to supply air and data from sensors, a control valve with a drive for the supply of heat carrier.

- The air temperature changes as a result of receiving data from the thermostat.

- When the system is turned off, the air damper, the valve on the coolant supply and the fan are closed. If there is a risk of freezing, the automation does the same and opens the valve.

- If a timer is available, the regulator can turn on and off the heating at a specified time.

- By connecting sensors, it is possible to fine-tune the microclimate in the room.

The proposed thermal automation schemes are not very difficult to implement. Therefore, they can be implemented with minimal skills and installation experience. You can perform the described work on the deployment of such systems yourself.

Alphanumeric designations on automation diagrams

1-1a - pre-regulated radiator valve;

2 - radiator shut-off valve;

3, 3a, 3b - indoor and outdoor temperature sensors;

5 - temperature sensor of the coolant in the supply line and on the "return", installed after the boiler generator;

6, 6a - adjustable valves;

7 - electric gear drive;

8 - direct temperature regulator;

9, 9a - adjustable valve for pressure drop control;

10 - bypass valve;

11 - heat meter;

12 - ultrasonic flow meter;

13 - vane flow meter with pulse output;

14 - temperature sensors of the heat meter;

15 - shut-off valves;

16 - check valve;

17 - mesh filter;

18 - drain cock with a hose nozzle;

19 - pump for forced circulation;

20 - flow regulator (limiter);

21 - automatic air vent;

22 - electromagnetic valve with pressure sensor;

23 - expansion tank;

24 - coolant temperature limiter on the "return";

25 - balancing valve (automatic);

26 - shut-off and measuring valve;

27 - water heater;

28 - air heater (air heater);

29 - fan;

30 - air damper;

31, 31a - connecting elements for radiators;

32 - programmer;

33 - boiler generator;

34 - motorized valve-switch with a returnable spring;

35 - room thermostat;

36 - thermostat for hot water supply;

37 - thermostat for protection of the air heater at low temperatures (protection of the system from freezing when the heating is turned off).

Order an automation project for heating

Buy a boiler for automatic heating

Automation of hot water supply systems