heating equipment

FOCUS TERMO

With a love of engineering

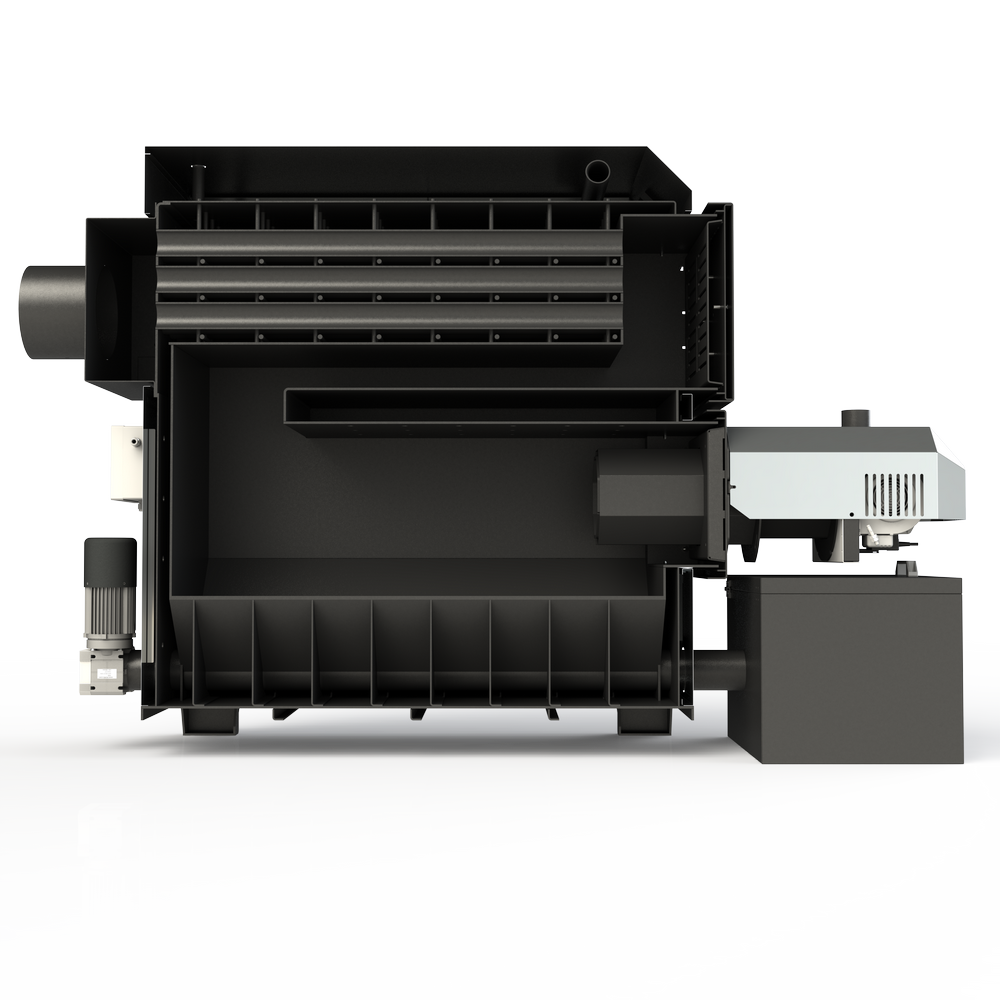

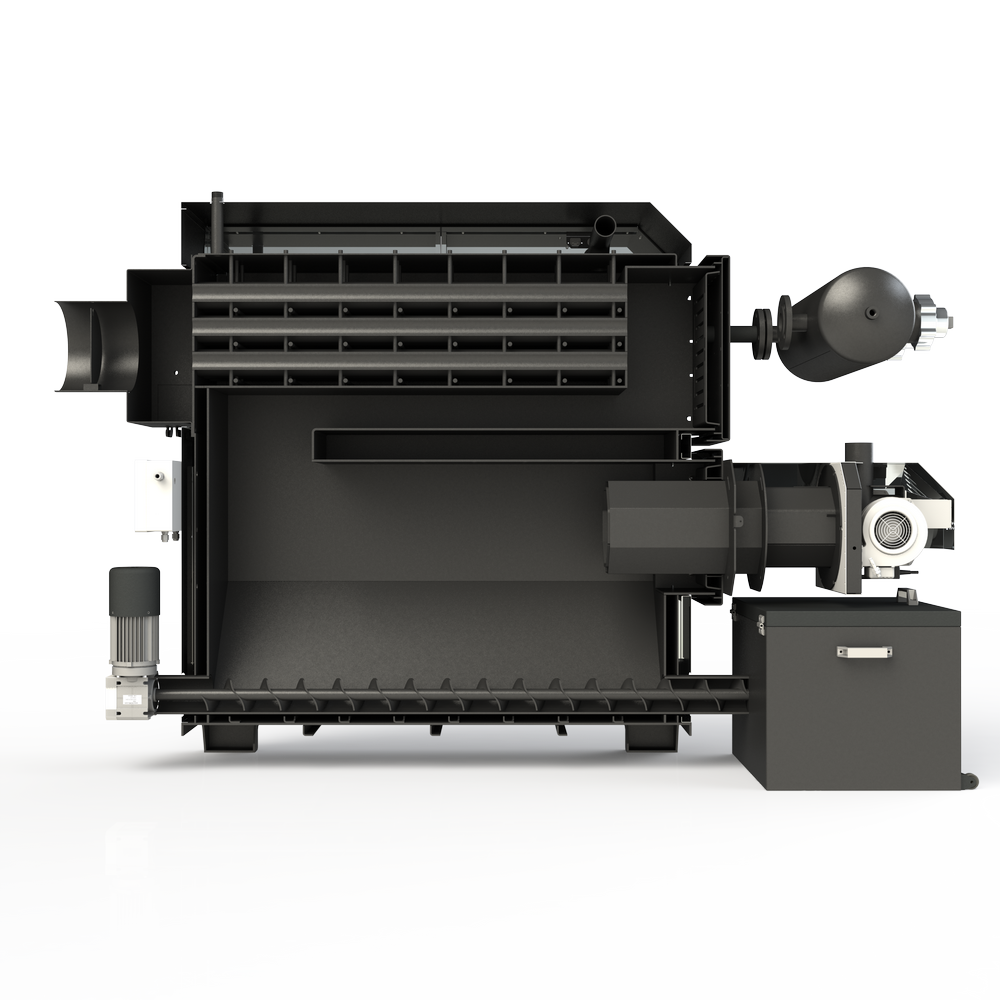

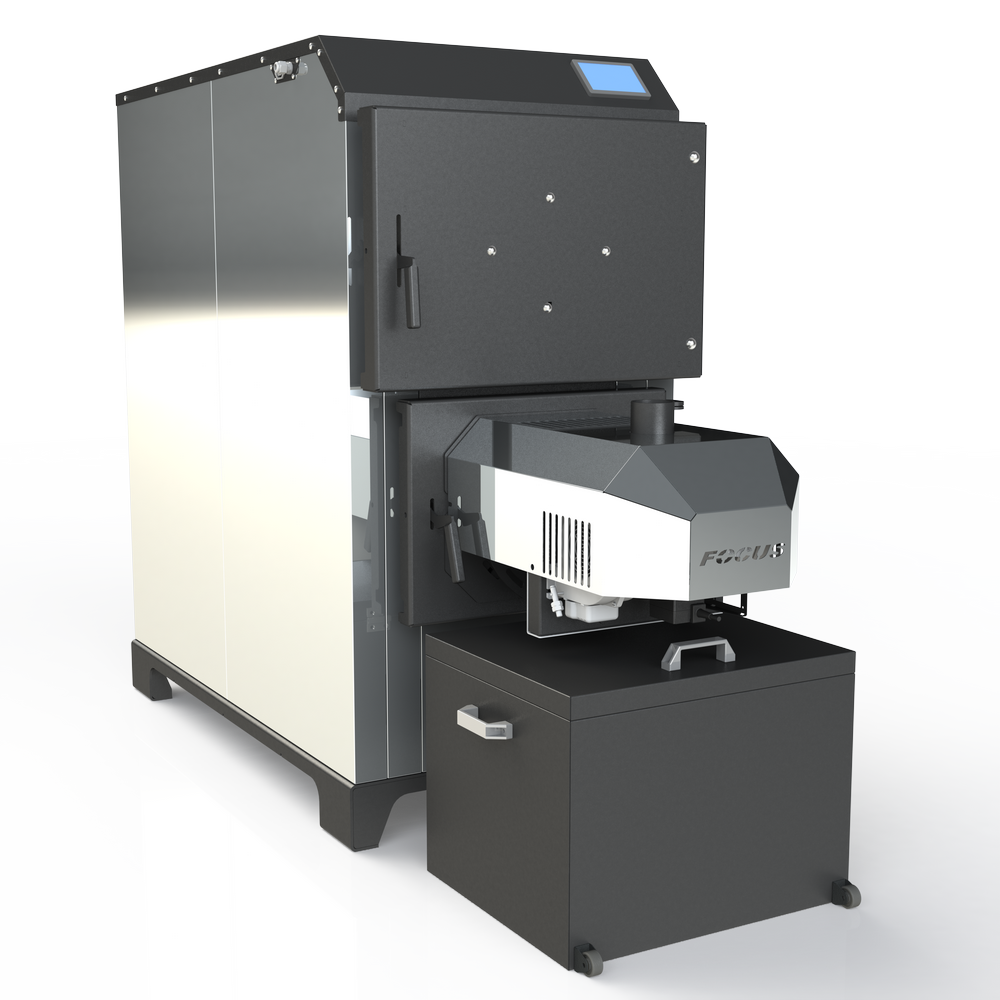

By purchasing a self-cleaning pellet boiler, you will not have to clean the heat exchanger once a month. The offered models with a power of up to 2000 kW (with a cascade connection of up to 20 MW) are equipped with an ash removal system with a roll-away container, as well as pneumatic cleaning, which allows increasing the intervals between maintenance.

Pick up a modelModels with built-in ash filter and roll-away container

Models with ash removal and automatic pneumatic cleaning

Order a turnkey boiler room and get installation

equipment by our specialists free of charge.

The deposition of soot and ash on the heat exchanger leads to the formation of an insulating layer.

Continuous heat generation is important for facilities such as factories and greenhouses.

Boiler cleaning is necessary, but high labor intensity leads to longer maintenance periods.

The microcontroller automates the operation of the boiler, pneumatic cleaning and fuel supply.

Sliding ash pans have a large capacity and are designed for use in industrial environments.

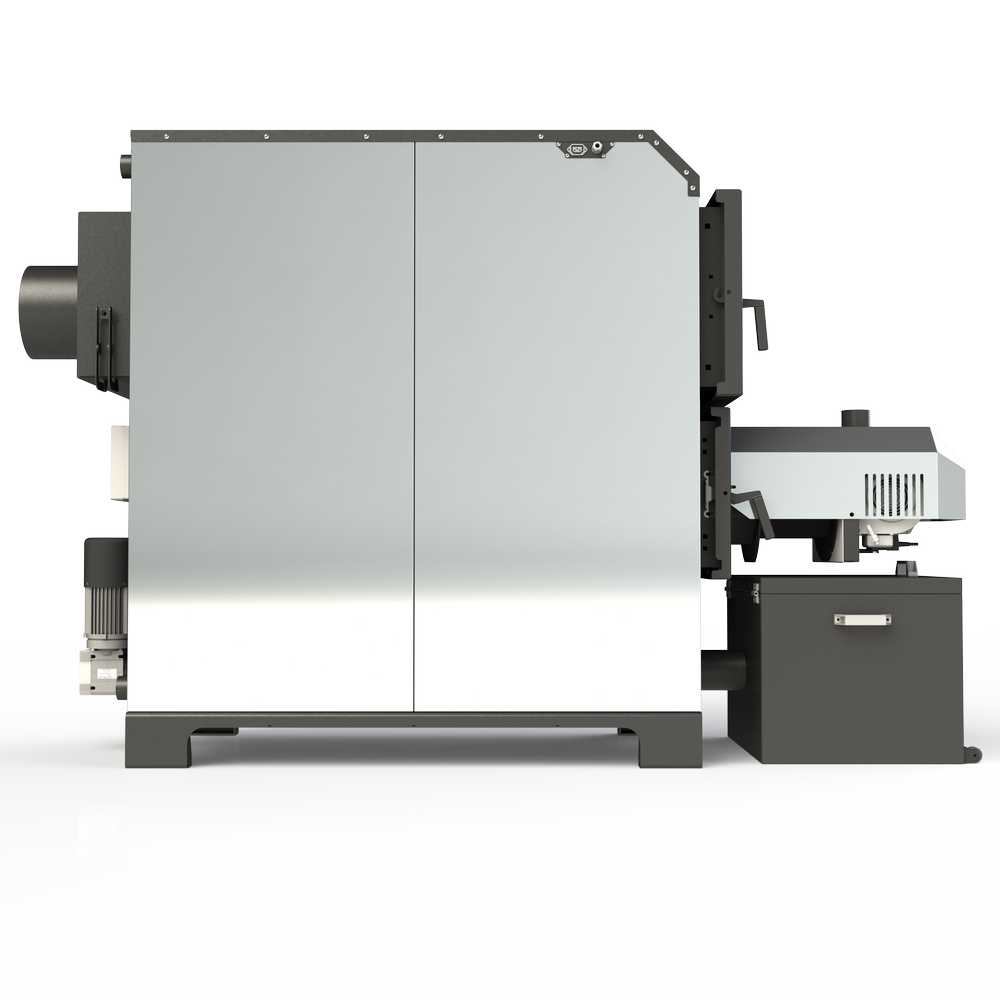

The compact dimensions of the boiler make it possible to complete high-performance boiler rooms.

The boilers are designed for heating houses, greenhouses and industries with a cascade connection with a power of up to 2.5 MW.

All models of self-cleaning boilers are equipped with a screw ash filter built into the heat exchanger.

Pneumatic cleaning, which greatly simplifies boiler cleaning, is offered only for certain boiler models.

Adjust the intervals between pneumatic cleaning depending on your requirements and fuel contamination.

Optionally equipped with ready-made piping with a three-way or four-way valve and IMP Pumps.

The boiler is equipped with a Victaulic quick connection system that allows for slight distortions during installation.

The FOCUS self-cleaning pellet boiler is additionally equipped with a screw ash removal system into roll-off containers. This guarantees an increase in the useful life of the boiler without reducing the efficiency between boiler servicing. Built-in pneumatic cleaning with programmable operating periods improves the results of removing ash from the heat exchanger.

At the same time, the time of continuous heat generation increases, which is especially important in factories, greenhouses and other facilities where special attention is paid to the stability of heat supply. Cascade installation of boilers will make heating uniform and continuous, regardless of the fuel load for all boiler equipment.

The design solution for cleaning a pellet boiler includes a screw ash removal system from the ash pan into containers for collecting ash. Ash is also disposed of in the boiler ash pan by a screw system from the grate space and naturally from the pellet burner. Automation and roll-away parts simplify regular maintenance of the boiler and make it suitable for use in households, reducing the labor intensity of cleaning.

Pneumatic cleaning operates on a safe low-voltage 24 V power supply. The system includes a receiver and electric valves. If autonomy is required, pumps and electrical components can be connected to a solar power supply system.

The boiler design includes a hybrid heat exchanger. The plate type relieves the flame tension and deposits the bulk of heavy particles, which is especially important when the boiler operates on high-ash granules.

The most developed convective fire-tube part of the heat exchanger corresponds to real heat exchange. Pneumatic boiler cleaning helps maintain high efficiency.

Regular cleaning of industrial boilers requires the hiring of special teams; in this case, the cleaning procedure is performed automatically.

Mechanical cleaning can be neglected when choosing boilers with ash removal for a municipal boiler house, avoiding the need to hire an operating crew.

Maintenance of boiler rooms from 2000 kW to 20 MW for greenhouses is carried out on their own when purchasing self-cleaning FOCUS boilers with ash removal and pneumatic cleaning.

The advantage of FOCUS self-cleaning boilers is that they operate on high-ash fuel pellets, the combustion products of which require regular cleaning of the boiler. Screw ash removal and automatic cleaning allow this to be done in a fully automatic mode to make the proposed equipment require minimal maintenance.

The purchase of FOCUS self-cleaning boilers will make it possible to optimize the cost of maintaining maintenance personnel, reducing manual and labor-intensive labor of high complexity and harmfulness to a minimum. At home, such equipment with regular automatic cleaning of the boiler can be serviced by women and the elderly.

Stainless steel AISI201 brushed

Capacity of industrial type ash containers.

For a tight fit of the ash pit door and heat exchanger to the opening.

Installed 2 ceramic FKK candles for contactless air ignition of pellets.

Composition elements made of heat-resistant chromium cast iron ChH32.

Structural steel 09G2S.

A built-in infrared sensor is used to monitor the level of flame radiation.

Built-in burner auger temperature sensor (automation switches off the fuel supply and issues an alarm signal).

All burner models have a “break” in the fuel supply line for reliable operation of the equipment.

The Ukrainian manufacturer of solid fuel boilers FOCUS was the first to implement automatic cleaning of the body exchanger in a pellet boiler, which greatly simplifies operation. Design features and fuel combustion with secondary air supply eliminate the need to clean the chimney, ensuring an impeccable level of environmental friendliness of emissions when using high-ash pellets.

You can now perform mechanical cleaning and flushing of the heat exchanger much less frequently, and self-cleaning boilers can be easily operated by women and pensioners. As a result of regular pneumatic cleaning of the surface and walls of the heat exchanger, the maximum heat removal efficiency is constantly maintained.

These qualities are complemented by exceptional economic benefits due to the use of cheap granules and unprecedented operational safety.

Regular cleaning, which is required to maintain the efficiency of solid fuel boilers, complicates the maintenance of heating equipment. For this reason, consumers are trying to purchase an efficient, small, but expensive gas wall-mounted boiler. At the same time, there is no economic benefit during the initial installation.

FOCUS premium heating equipment does not have the disadvantages of solid fuel boilers, but retains and multiplies the advantages many times over, ensuring complete autonomy. When purchasing our boiler, it will require service at the same level as gas boilers; regular cleaning will be performed by automation.

All models are assembled using industrial boiler components and appropriate cleaning methods.

If you want to install autonomous heating, but avoid cleaning the heat exchanger and chimneys, choose the FOCUS self-cleaning boiler. You will forever forget what it is like to clean a solid fuel boiler.