Boiler rooms with solid fuel boilers with pellet burners for enterprises

Boiler rooms with solid fuel boilers with pellet burner can be used in manufacturing plants to provide a variety of heat and energy needs, while providing environmental friendliness and economic benefits.

(*) The photo shows a FOCUS boiler without a pellet burner, but it provides for its easy installation by replacing the combustion chamber doors.

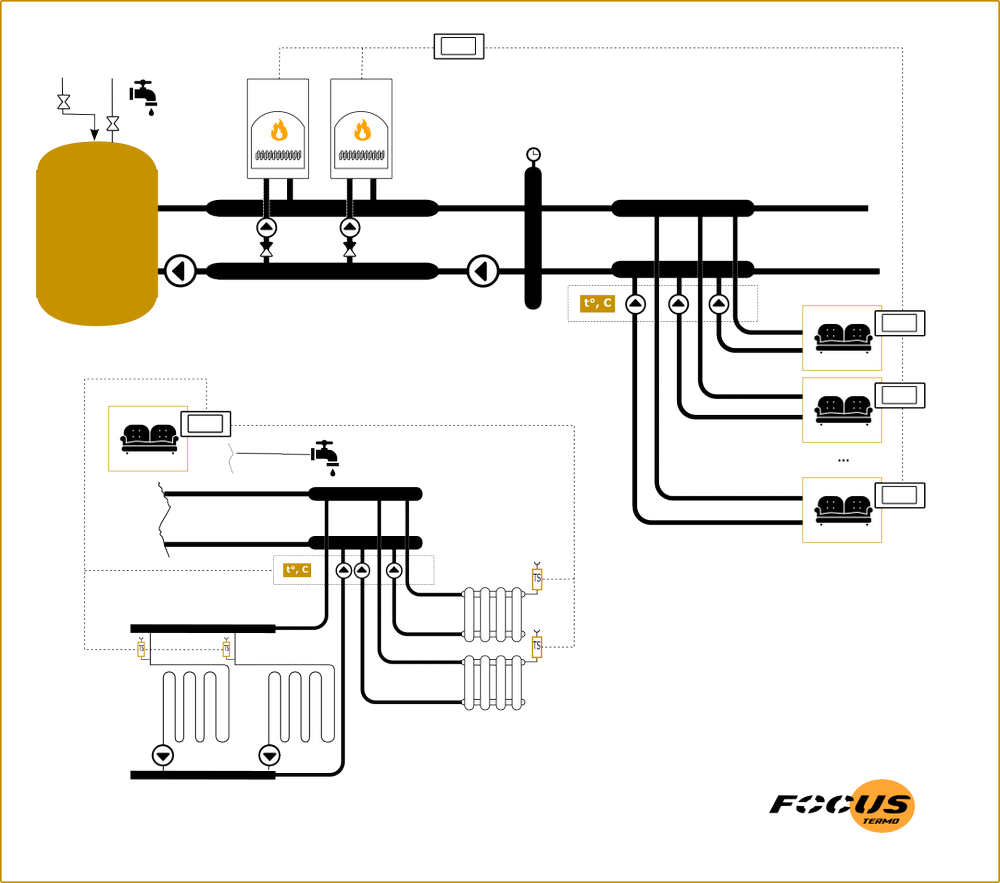

The main purpose of boiler houses with solid fuel boilers at industrial enterprises is to provide heat supply to industrial premises, offices, warehouses and other buildings on the territory of the enterprise. An important function is the heating of industrial premises, but it is implemented according to a different principle.

Also, some manufacturing processes require thermal energy for heating raw materials, processing materials, evaporation, or other purposes. Boiler houses with solid fuel boilers can be used to meet this heat demand. Depending on the tasks, obviously, the choice of TT boilers differs.

For example, such boiler rooms can also be used to heat water for domestic needs, industrial processes or to provide hot water supply in an enterprise. In some cases, they are used to produce steam, which is necessary in various production processes such as sterilization, cleaning, rinsing and others. For these purposes they are mainly used steam generators, also operating on solid fuel.

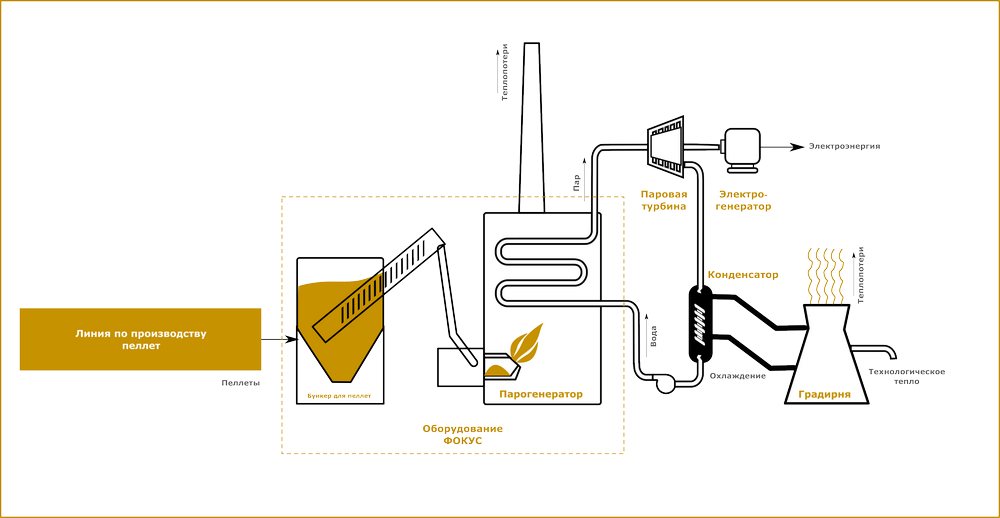

In some cases, boiler houses can operate not only to provide heat supply, but also to produce electricity. This is possible by using turbines or generators that run on steam produced by the boiler house. An example of such a thermal power plant operating on pellet fuel is shown in the illustration.

Using solid fuel boilers with pellet burners can be a more environmentally friendly option compared to traditional fuels such as coal or heavy oil. Pellets produce fewer harmful emissions and can be more energy efficient due to a special flare-type combustion process. when the efficiency reaches 95%. But everything depends on the availability of fuel and its cost, as well as the type of production for which the appropriate equipment is selected.

Pellet boiler rooms used for heating and ensuring production processes of energy-efficient enterprises. They can be made in a block-modular format and placed in a separate van, which greatly simplifies the initial installation and allows the use of such a modular boiler room at different sites.

To understand the difference between a conventional pellet boiler and a TT boiler with a pellet burner, it is worth analyzing the types of fuel. Boilers that allow production to use different types of energy resources provide a higher level of energy security in production processes.

Mini-thermal power plant on pellets

Types of solid fuels

We are talking about any type of fuel that is in a solid state and is used to produce thermal energy during the combustion process. In the production processes of enterprises, various types of solid fuel can be used depending on the specifics of production, technological requirements, availability and economic factors. Boiler rooms with solid fuel boilers with pellet burners are a universal solution.

Here are some of the most common types of solid fuels:

- Coal: Coal is one of the most common solid fuels used in industrial boilers and is widely used in a variety of manufacturing processes. It can be purchased for space heating, steam and electricity generation, metal smelting and other industrial purposes.

- Firewood: Firewood is a traditional and environmentally friendly source of heat. They are often purchased for space heating, especially in rural areas where firewood may be available or even free.

- Pellets: Pellets are compressed granules made from wood or other biomass. They are used in pellet boilers for space heating, hot water supply and electricity production. Pellet pellets can also be used in industrial processes, such as combustion in special furnaces or material processing boilers.

- Peat: Peat is an organic fuel obtained from decomposed plant residues. It can be used for heating, energy generation and in industry for the production of peat briquettes or peat coal.

- Briquettes and wood waste: Briquettes and wood waste can be used as solid fuel for heating, steam generation and energy production. They are often made from waste from wood processing or agricultural processes.

- Other types of solid fuel: Other types of solid fuels may include biomass, wood waste, wine stills, charcoal and others. These fuels can be used in various manufacturing industries depending on their characteristics and availability.

In other words, by installing a pellet boiler house while maintaining the manual loading function, the enterprise gives itself the opportunity to use various available types of fuel to provide heat for production processes, including coal, peat, briquettes and firewood. In all cases, it is possible to automate heating and its uninterrupted supply to the system.

Eventually…

A pellet boiler house with a solid fuel boiler with manual loading of the appropriate power is the optimal solution for production, allowing you to scale heat generation in the required range of values thanks to a cascade connection. Despite the fact that this is a modern solution for a fully automated pellet boiler room, which can, if necessary, operate on any solid fuel. Depending on the nature of the hydraulic piping of the boiler circuit, the level of automation is maintained or slightly reduced. But independence from one type of fuel is a good help for industrial enterprises.

Automated boiler rooms for production