Designs of heat exchangers ..., or how to make inexpensive heating

The efficiency of energy consumption will depend entirely on the ability of the heating unit to accumulate heat. This is done and depends on the design of the heat exchangers. The better this part of the heating device is selected, the more affordable heating becomes in your home.

The heat exchanger is a circuit in which the energy of the fuel is transferred to the coolant supplied to the batteries. In other words, if we take a pellet boiler as an example, the heat generated during combustion in the form of smoke passes through a tubular heat exchanger, which removes heat from the combustion products.

The efficiency of heating depends on many parameters, but the main element is the heat exchanger and its design. Heat transfer is directly proportional to the contact area. For this reason, the design assumes the maximum increase in this characteristic.

Types of heat exchanger designs and their role in inexpensive heating

There are two types of heat exchangers that are used in heating appliances:

- surface, in which heat transfer between media is carried out through a common exchange surface - usually a blank metal wall;

- mixing heat exchangers, in which heat is transferred when the media come into contact.

Less often, various regenerative heat exchangers and recuperators are used, in which the heat carrier is heated due to surface contact with previously heated structures. For example, with a nozzle that is heated by another coolant. This secondary heat transfer design is typical for buffer tanks, which are recommended to be installed for solid fuel boilers (not pellet).

Most often, surface heat exchangers are used, the types and shapes of which have significant differences. There are also standard designs, normalized by parameters and standards.

There are structural types of heat exchangers that have significant differences and differ in the principle of heat transfer:

- tubular;

- lamellar;

- spiral;

- coils and others of little use.

Materials for heat exchangers

For the exchange of heat by different media, it is advisable to choose a material with high heat transfer and the ability to accumulate thermal energy. Copper is considered the most suitable, but copper heat exchangers are quite rare due to their high cost. Typically, such structures are made of carbon and alloy metals, less often of titanium and tantalum, which is more typical for industrial units.

Specialized thermal steel is not produced in Ukraine, ferrous metal from carbon steel is considered the best choice, since stainless steel does not provide maximum performance, but is more expensive.

Despite the rather large number of normalized designs of heat exchangers, preference is given to simple and easy-to-clean elements of heating devices, as well as designs that imply convenient installation and provide easy access to the heat exchange surface.

A very non-standard heat exchanger, but widely used in everyday life, is a ceramic brick or any other stone. These are the materials from which stoves have been built since ancient times. In addition to the primary heat transfer during combustion, the ceramics of the stove or the stone of the fireplace body accumulates heat well and provides long-term heating of the air masses around the stove, being, in fact, a large-area secondary mixing heat exchanger.

It follows from this that the heat exchanger, in contact with the products of combustion, can be contaminated, resulting in a decrease in heat transfer and heat transfer between the exchange media. Designs of semi-industrial heating devices, for example, solid fuel boilers TM "Focus" with a door adapter for pellet burners imply cleaning the heat exchanger of soot by shaking or using a pneumatic system during automatic cleaning.

It is also necessary to take into account the fact that the efficiency of fuel use depends on the temperature of its combustion, the efficiency of combustion of primary combustion products. The better the fuel is burned, the more inexpensive heating you get, the safer the emissions into the atmosphere.

Tubular heat exchangers

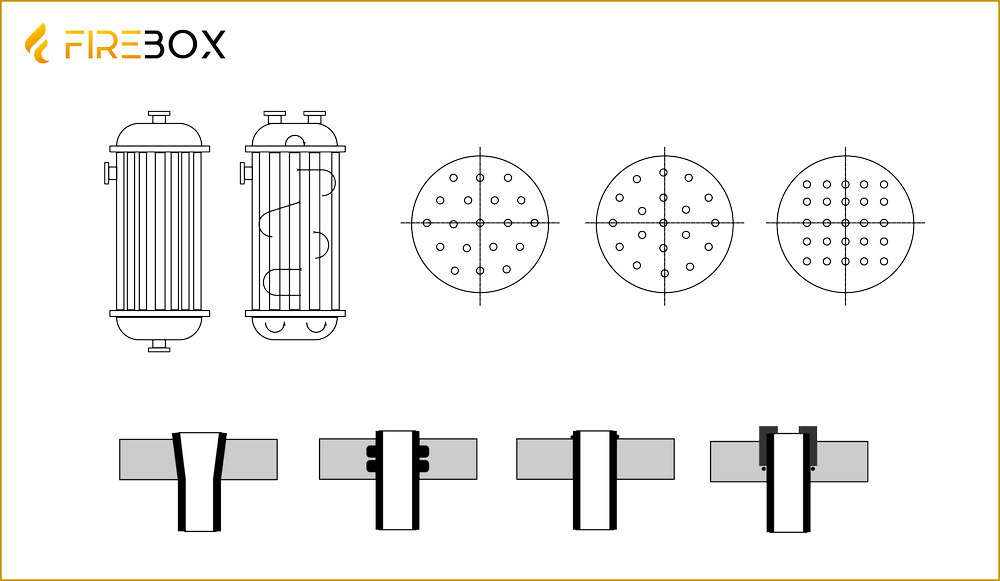

Shell and tube heat exchange circuits

These are the most used heat exchangers in industrial and semi-industrial boilers, including gas and solid fuel domestic class. The figure shows the basic design, which includes a housing (casing) and a bundle of pipes welded to it. In such a heat exchanger, one medium, usually a coolant, moves inside the pipe (usually water), the second - in the medium between the pipes (usually air).

A feature of this type of heat exchangers is the counterflow of media. In this case, maximum heat transfer is ensured. This is due to the direction in which the heat exchange medium naturally moves when the density changes under conditions of heating and its temperature decreases.

The counterflow also provides a uniform distribution of velocities and heat transfer conditions proportional to the cross-sectional area of the tube from the bundle. With an alternative flushing of the tubular element, in the case of hot or cold water supply, it will accumulate in one of the parts of the beam heat exchanger, at the top or bottom, forming "stagnation zones".

The placement of the tubes in the bundle also has implications for heat transfer. Usually they are placed at the vertices of a hexagon or along concentric circles (less often). When convenient cleaning of the heat exchange surface is required, pipes are placed in a bundle along the vertices of a rectangle (corridor placement).

The pipes are fixed by flaring, avoiding various threaded fasteners (allowed in domestic boilers). But the strongest connection is provided in holes with annular grooves, which are filled with pipe material during flaring. In some cases, pipes are fixed by welding. Other types of pipe connections are allowed, including soldering. Solder mainly copper and brass pipes.

An alternative is the fastening with glands, which implies a quick replacement. However, the connection is complex, unjustified in price and unreliable.

The designs of this type of heat exchangers are one- and two-way. Single-pass heat exchangers have a low speed of movement of the coolant, that is, the heat transfer is quite low. This is typical for gravity systems without a pump. To increase heat transfer in such systems, increase the length of the pipes and reduce the diameter. Such designs are not very convenient, therefore, an alternative version is used - multi-pass heat exchangers.

Multi-pass tubes in a bundle are more suitable for industrial production, as they require the presence of transverse baffles in the tube cavity. Such sectional beam tubes can be made by skilled craftsmen. Keep in mind that the breakdown must be the same in all pipes and there must be the same number of strokes to ensure the same heat transfer parameters.

Due to the design, the flow rate of the liquid in multi-pass heat exchangers increases (in number of times in terms of the number of passes) with the same indicators of the heater, and you get inexpensive heating due to efficient heat extraction. In multi-pass designs of heat exchangers, baffles are used, which also serve as supports for the tube bundle.

It should be taken into account that an increase in the intensity of heat transfer contributes to an increase in the resistance of the medium, which implies a more complex design of heat transfer, which can only be obtained using special calculations. The economically feasible number of moves usually does not exceed 5-6. The coolant for such heat exchangers must be specially prepared in order to eliminate oxygen and non-condensable gases from the liquid. Purge valves are used to eliminate blockages.

Horizontal heat exchangers are more popular, they operate in industrial heating systems at high speeds and eliminate the stratification of liquids that occurs due to temperature and density differences, and also eliminate the formation of stagnant zones.

To create a certain voltage and achieve a given speed, the tubes of the bundle and the casing are elongated unequally. Shell and tube heat exchangers can be designed with compensating devices: lens condenser, floating head, U-tubes. This is done to reduce pipe deformations associated with the temperature difference between the pipes and casing, the length of the pipes, the difference in pipe and casing materials, including to compensate for excess pressure. Although efficient, complex heat exchanger circuits are difficult to clean.

Such heat exchange circuits are standardized according to DSTU 9929-67.

Element heat exchangers

This type of heat exchangers follows the modular principle. The heat exchange circuit consists of individual heating elements, each of which is a shell-and-tube circuit. The advantage of this design is the simplification of the manufacture of the heat exchange circuit compared to the multi-pass version, ease of installation and cleaning during operation, an increase in the coolant circulation rate along with a higher heat transfer.

This type of circuit is not suitable for large boiler rooms, as the size of the equipment increases significantly.

Heat exchangers of the "pipe in pipe" type (two-pipe)

Two-pipe heat exchangers are a “pipe-in-pipe” design, the coolant moves in them both in the inner and outer pipes, providing step-by-step heat transfer and removal. The internal elements of the "pipe in pipe" type are connected by "kalachi", the external - by branch pipes.

The high speed of fluid movement is ensured by small cross sections of 1–1.5 m/s. This design is particularly suitable for boilers with high operating pressures. If a larger heat-conducting surface is required, heat exchangers of this type are made in several pipe-in-pipe sections.

Plate heat exchangers

This type of heat exchanger uses corrugated parallel plates, which creates a system of narrow channels with a width of only 3-6 mm. This feature makes a plate heat exchanger more efficient than a tube heat exchanger. Fluids move in channels between adjacent plates. As a result, high heat transfer coefficients of up to 3800 W/m2 [3000 kcal/(m2 h deg)] are possible even with very low flow resistance. These heat exchangers are not designed for high pressure operation.

Ribbed body exchanger design

Finned heat exchange circuits are among the most efficient. This design of the heat exchanger is suitable for coolant with a low heat transfer value (gases and viscous liquids).

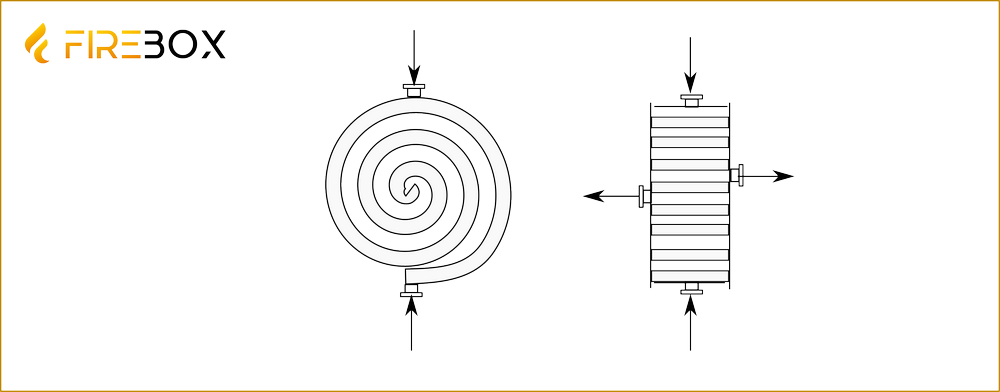

Coil designs of heat exchangers

This is a special type of heat exchangers used in heating devices where fluctuations in the regime are possible. In this design, the heat exchange circuit is implemented using a spiral coil with pipes 15-75 mm, which is placed in a liquid. The heat transfer coefficient is quite low due to the low velocity of the liquid. Heat is transferred by free convection. The speeds are increased by the design of the inner shell in the housing, and the heat exchangers themselves operate at a low thermal load. Despite their low efficiency, coil heat exchangers are widely used due to their simple design, low cost, easy repair and cleaning.

Such designs of heat exchangers work successfully under high pressure conditions and in chemical environments, but are used for heating surfaces up to 10-15 square meters. m.

This type of heat exchange circuit is popular in applications where steam is used for heating. In this case, the ratio of the length of the coil to the diameter does not exceed a certain limit, but depends on the pressure. For example, a coefficient of 200-275 is applied at steam pressures of 2-5 atmospheres, otherwise steam condensate will accumulate in the lower part of the coil, which will contribute to loss of efficiency.

Spiral type of heat exchange circuits

For the manufacture of a spiral heat exchanger, two metal sheets are used, which are folded in a spiral. The inner ends are welded to a blank wall, and the outer ends are connected by welding to each other. This creates two insulated spiral channels with a large heat transfer surface.

The advantage of this type of heat exchangers is compactness, while providing a high speed of movement of the coolant. They are used for heating gases and condensing vapors and can operate at elevated pressures, but usually not higher than 10 atmospheres. Connections are the weak point of this type of heat exchangers; DSTU 12067-66 is used to achieve the best output quality.

Eventually…

From this overview, you can see what the designs of heat exchangers are in order to maximize heat transfer. The most applicable in heating devices are tubular and plate heat exchangers. Shell-and-tube structures are quite affordable for self-production. But it is necessary to take into account the efficiency of heat transfer and the general principle: the larger the capacity and cross-section of the heat exchanger, the lower the fluid velocity and the lower the heat transfer.

A well-thought-out design of the heat exchanger, corresponding to the combustion parameters of the fuel, have solid fuel boilers TM "Focus", which can be operated in two modes: when heated with wood and coal, or with a pellet burner, which is installed in a special door adapter. Despite the use of de facto solid fuel technology, pellet heating is completely autonomous and automated due to the automatic supply of fuel pellets and the processing of boiler states by a Polish-made microcontroller.