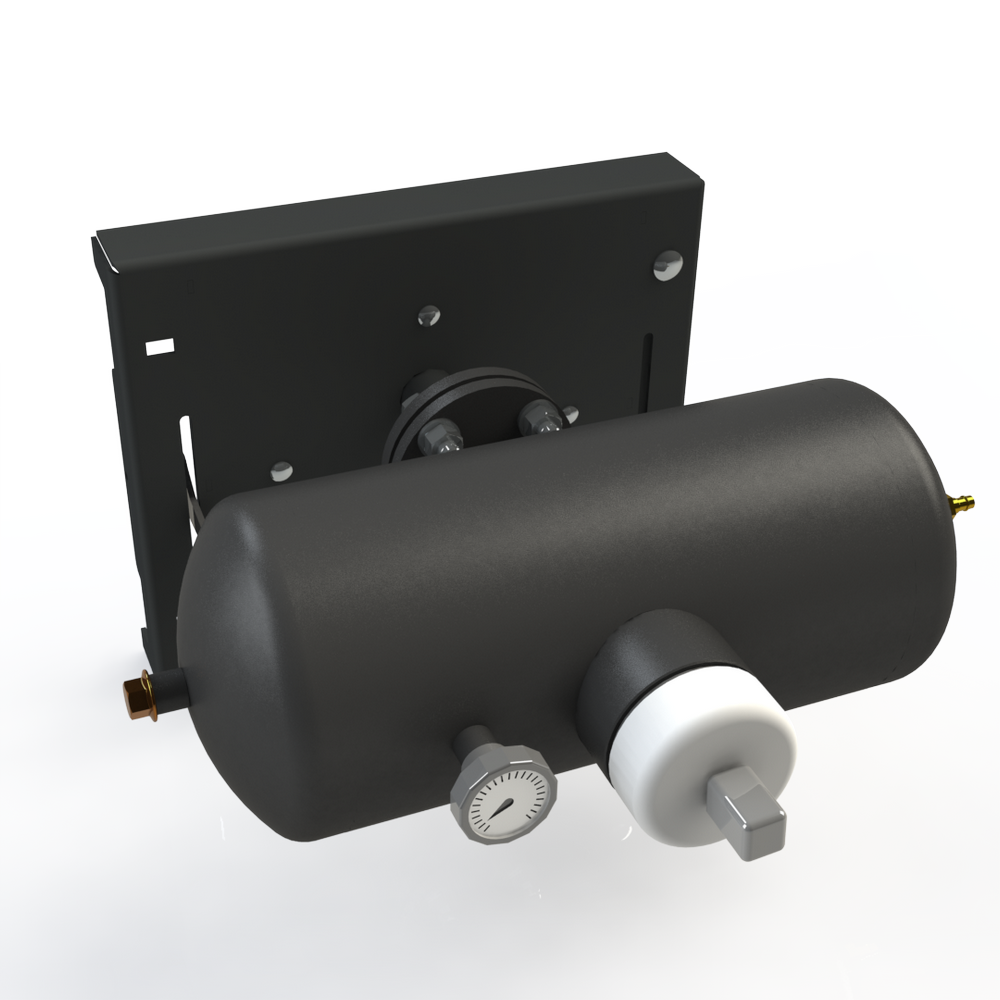

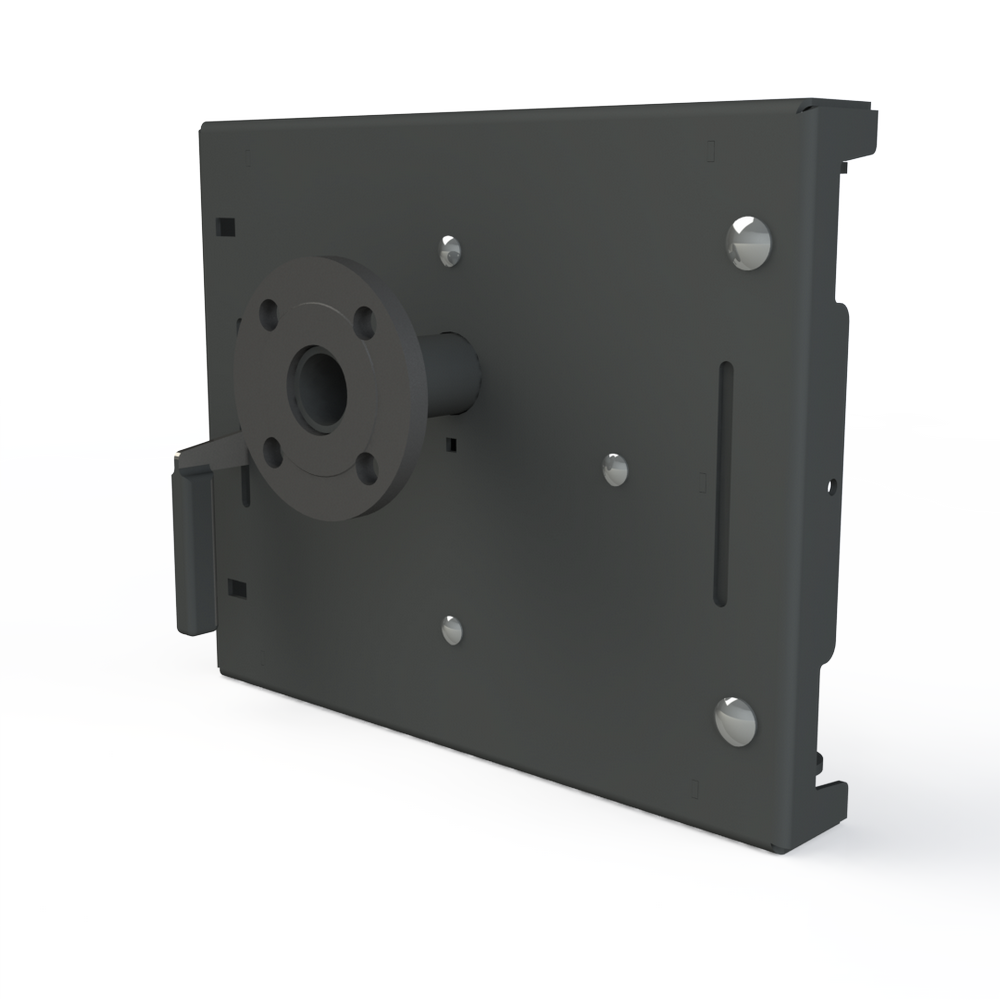

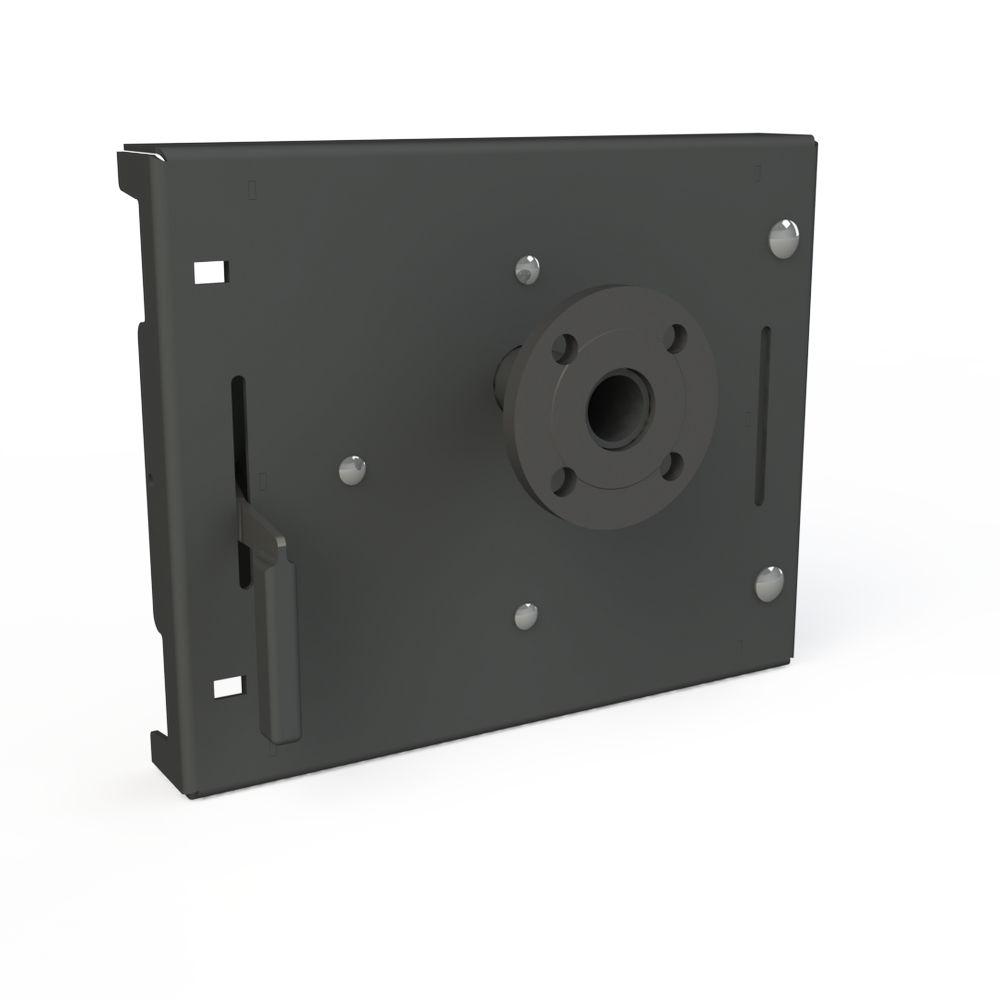

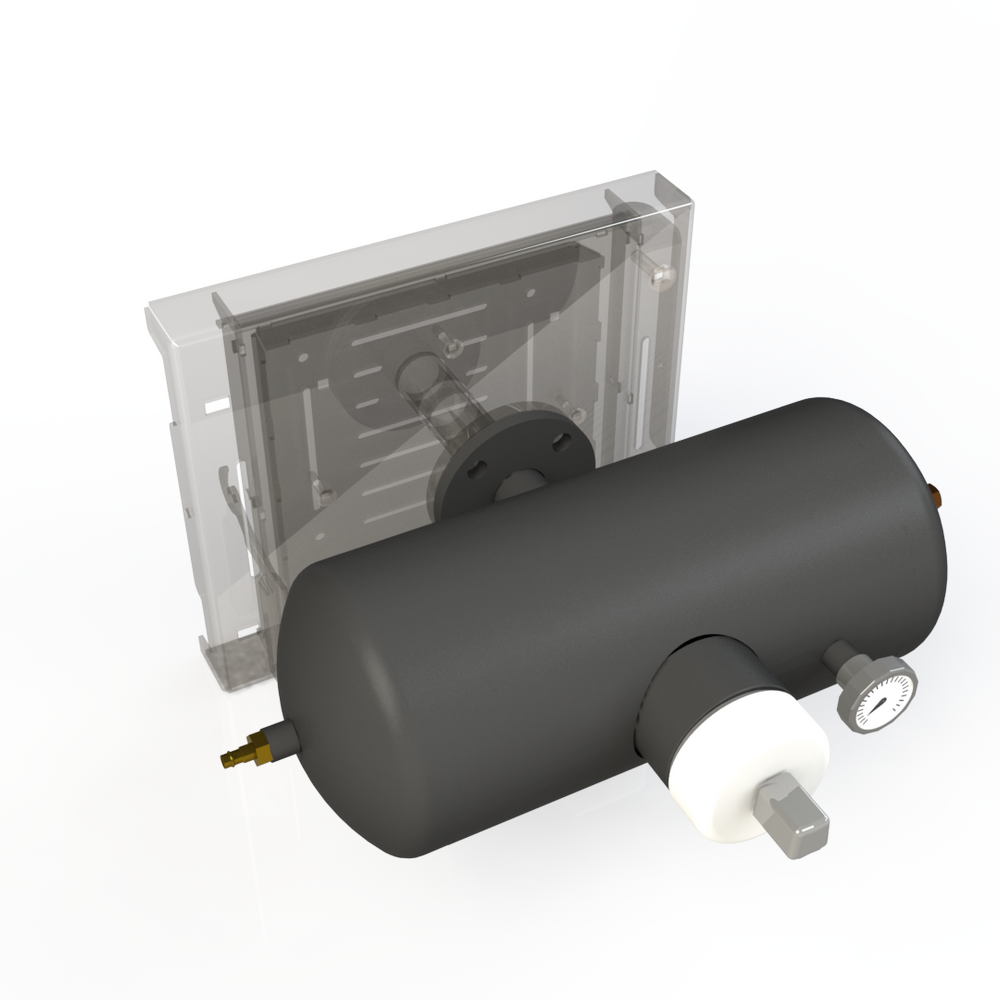

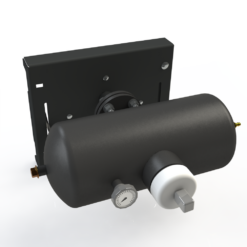

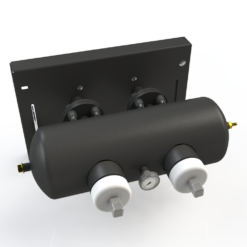

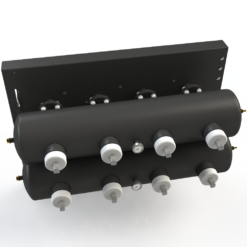

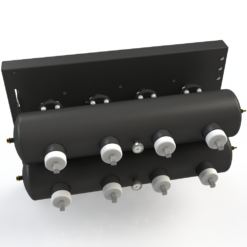

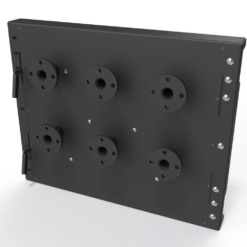

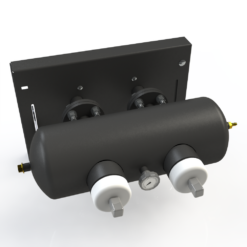

Pneumatic cleaning system for a 20-50 kW boiler for a private house

Combustion products tend to accumulate on the boiler walls and not conduct heat, ultimately reducing efficiency. Ash deposition occurs as a result of increased aerodynamic resistance. As a result, heating efficiency decreases. It is a well-known fact that boilers require soot cleaning, but this process is very labor-intensive and requires a complete shutdown of the boiler room. This is very difficult during low temperatures and creates significant inconveniences, including during independent operation and maintenance.

The 20-50 kW boiler pneumatic cleaning system performs cleaning automatically, using high-pressure compressed air to remove deposits on the walls and heat exchangers. Using such a system minimizes the number of full maintenance sessions and makes cleaning any boiler effortless. FOCUS equipment allows this to be done automatically at the required time intervals.

Boiler pneumatic cleaning system and its advantages:

- maintains the boiler efficiency level by removing combustion products from the walls of the heat exchanger;

- allows the use of continuous heat generation during low outdoor temperatures;

- removes deposits on the structure and elements of the combustion chamber;

- no need for manual labor.

This pneumatic cleaning system for 500-700 kW boilers allows to significantly increase the intervals between cleanings and reduce the need for manual work, suitable for both FOCUS solid fuel boilers and boilers from other manufacturers.

Reviews

There are no reviews yet.