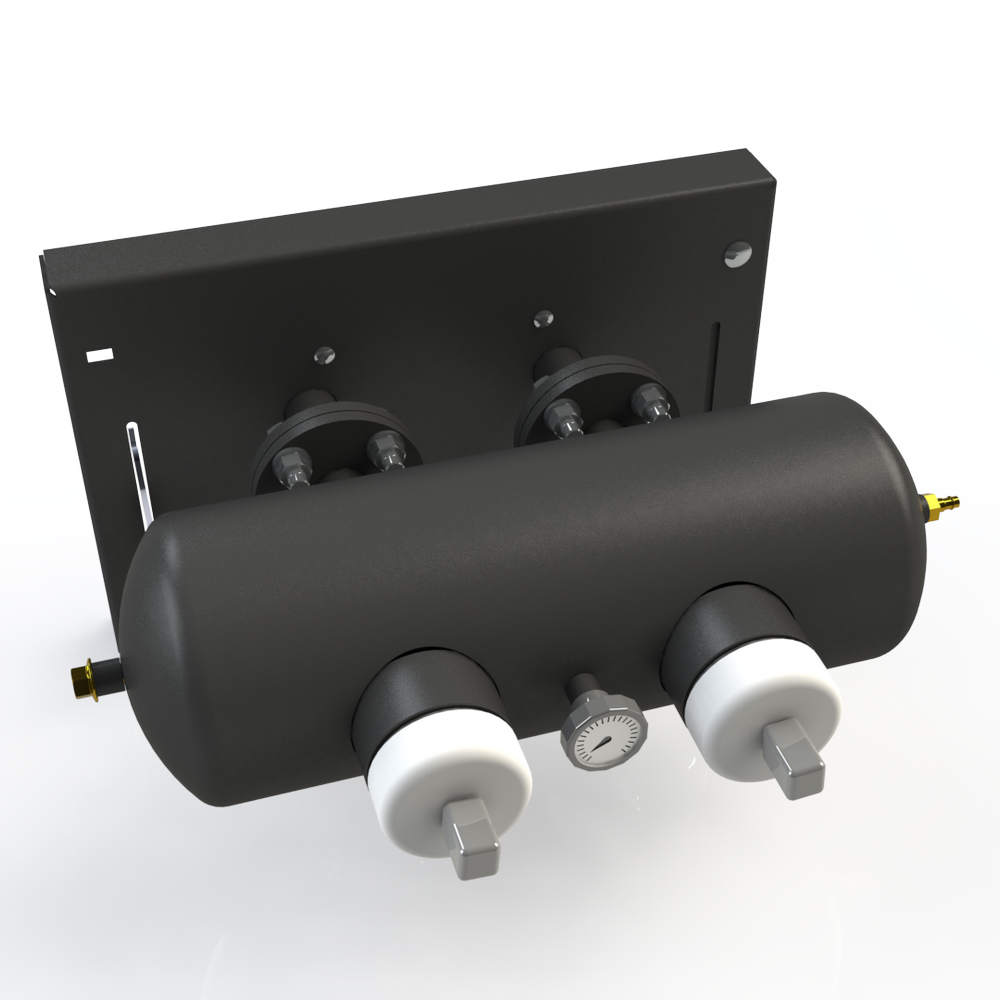

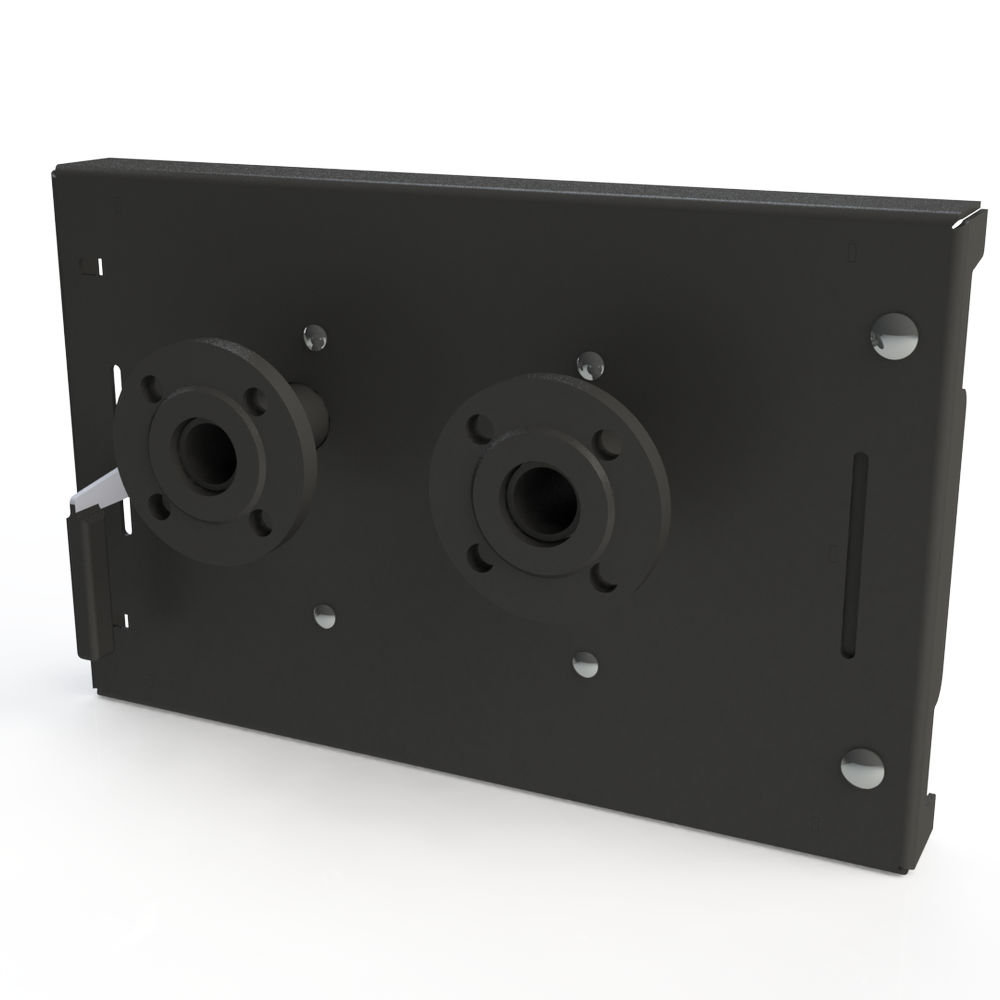

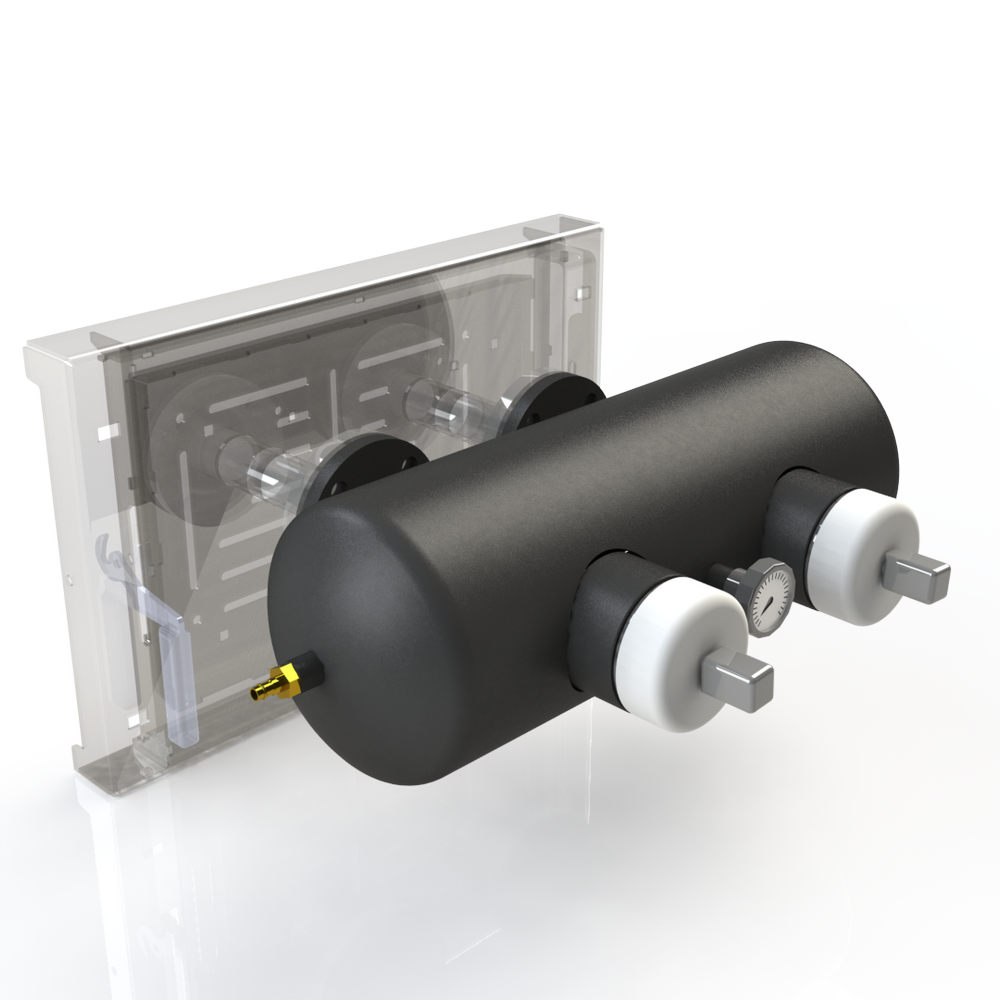

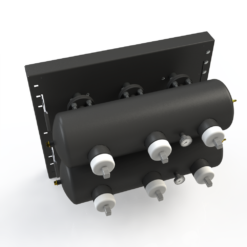

Pneumatic cleaning system for FOCUS 100-120 kW boilers: automatic boiler maintenance

During operation, boiler heat exchangers accumulate ash, which reduces their efficiency due to increased aerodynamic resistance. This leads to a decrease in the efficiency factor (EFF) and a decrease in the boiler capacity. Manual cleaning requires a complete shutdown of the equipment, creating inconvenience for both heat consumers and service personnel.

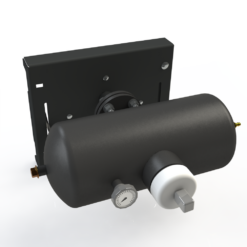

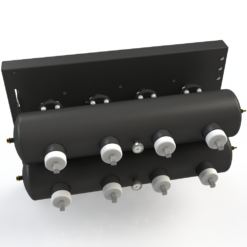

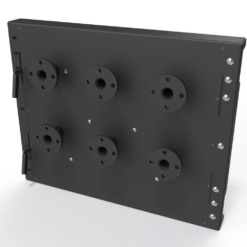

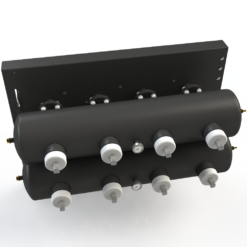

The FOCUS 100-120 kW Boiler Air Cleaning System automates this process, allowing the heat exchanger to be cleaned without having to shut down the boiler. It uses compressed air to remove ash deposits, helping to maintain optimum efficiency and extend the boiler’s uptime. The process involves regular high-pressure air blowing, which effectively dislodges and removes accumulated residues, maintaining high boiler performance and reliability.

FOCUS pneumatic cleaning system:

- increases the intervals between boiler cleanings;

- prolongs the time of continuous heat generation;

- ensures effective removal of deposits;

- reduces the need for manual maintenance.

This pneumatic cleaning system for FOCUS 100-120 kW boilers allows to significantly extend the time between cleanings and reduces the need for manual work, suitable for both FOCUS solid fuel boilers and boilers from other manufacturers.

Reviews

There are no reviews yet.