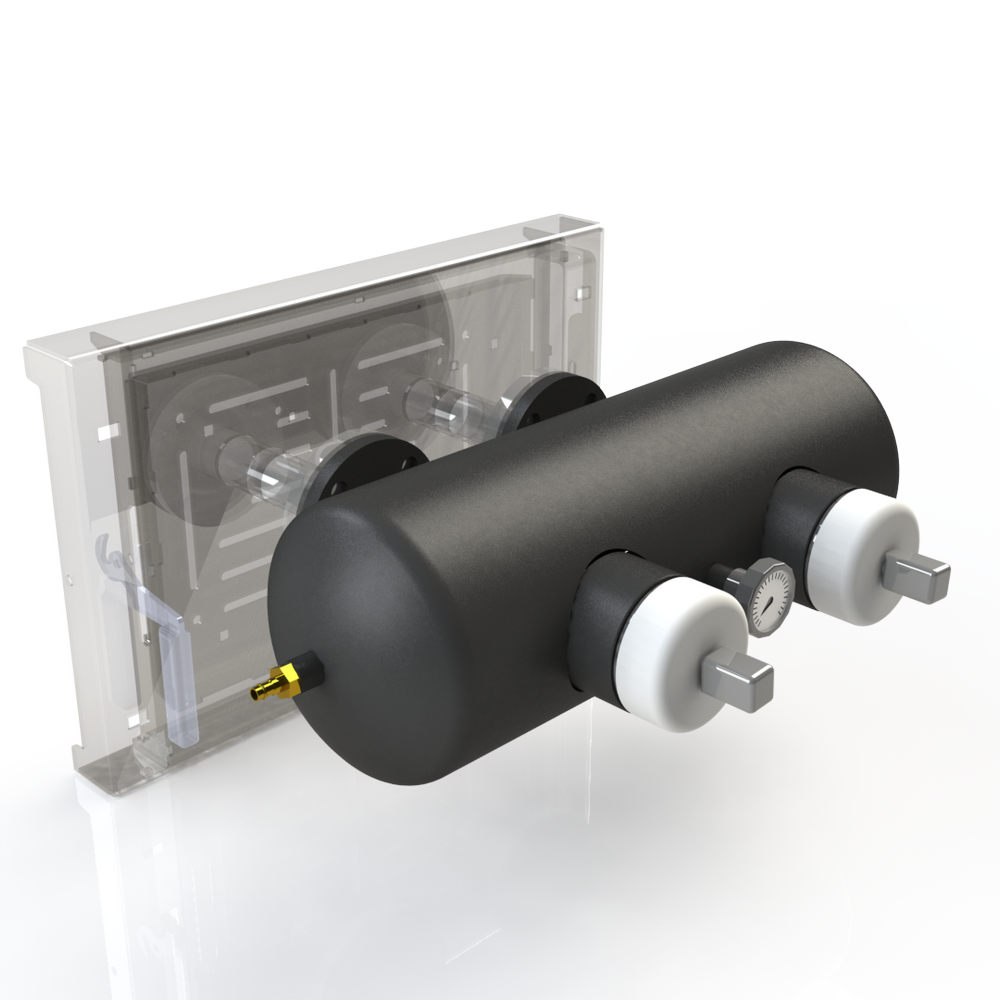

Pneumatic cleaning system for 60-80 kW boiler for self-installation

Combustion products tend to accumulate on the boiler walls and do not conduct heat, ultimately reducing efficiency. A 60-80 kW boiler pneumatic cleaning system can solve this problem, since ash deposition occurs as a result of increased aerodynamic resistance. As a result, heating efficiency decreases. It is a well-known fact that boilers require soot cleaning, but this process is very labor-intensive and requires a complete shutdown of the boiler room. This is very difficult during low temperatures and creates significant inconveniences, including during independent operation and maintenance.

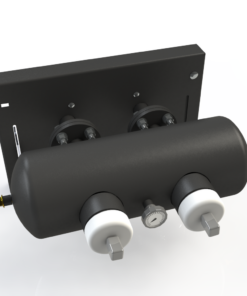

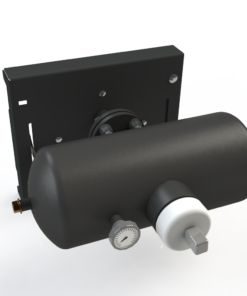

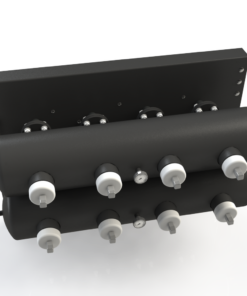

The 60-80 kW boiler pneumatic cleaning system performs cleaning automatically, using high-pressure compressed air to remove deposits on the walls and heat exchangers. Using such a system minimizes the number of full maintenance sessions and makes cleaning any boiler effortless.

The recommended device is a 60-80 kW boiler pneumatic cleaning system, suitable for all types of boilers.

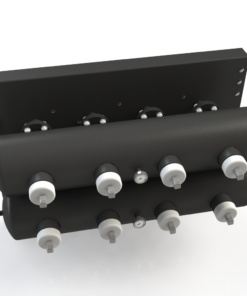

Boiler pneumatic cleaning system:

The 60-80 kW boiler pneumatic cleaning system offers a number of advantages:

- Maintaining efficiency: During boiler operation, combustion products such as ash and soot inevitably accumulate on the heat exchanger and combustion chamber walls. These deposits significantly reduce heat transfer and system efficiency. The pneumatic cleaning system regularly and effectively removes these contaminants using compressed air, which allows maintaining a high boiler efficiency, ensuring a stable and economical heat generation process.

- Continuous operation during the cold season: During low temperatures, it is important to maintain continuous heating to avoid interruptions in heat supply. Unlike manual cleaning, which requires a complete shutdown of the boiler for maintenance, the FOCUS 60-80 kW boiler pneumatic cleaning system allows cleaning without interruption in operation. This is especially important during periods of severe cold, when the boiler must operate at maximum load.

- Removing deposits in the combustion chamber: In addition to cleaning the heat exchanger, pneumatic cleaning removes deposits from other elements of the combustion chamber. This helps prevent excessive ash accumulation on the walls, improving the fuel combustion process and extending the service life of the equipment.

- Reduced need for manual maintenance: The system automates the cleaning process, minimizing the need for regular manual labor. This simplifies boiler maintenance and saves time for operators and technical personnel. Regular automatic cleaning reduces the need for full maintenance, making the operation of the equipment more convenient.

Thus, the FOCUS 60-80 kW boiler pneumatic cleaning system allows to significantly increase the intervals between maintenance sessions, reduces labor costs and is suitable for use with both FOCUS solid fuel boilers and equipment from other manufacturers.

The 60-80 kW boiler pneumatic cleaning system is an intelligent, software-controlled solution.

Reviews

There are no reviews yet.