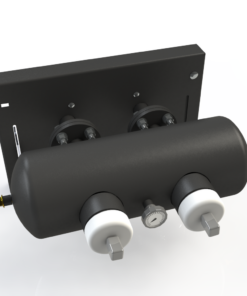

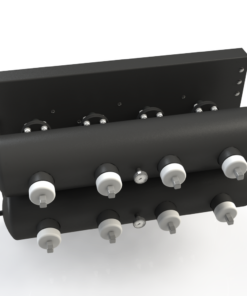

Pneumatic cleaning system for 100-150 kW boilers for self-installation

Over time, combustion products settle on the boiler walls, impairing heat transfer and reducing efficiency. Accumulated ash increases aerodynamic resistance, which leads to a decrease in heating efficiency and a decrease in boiler power. Regular soot cleaning is required to maintain stable operation of the heat exchanger, but this process often requires a complete shutdown of the equipment. This is especially inconvenient in the cold season and causes additional difficulties for users and maintenance personnel.

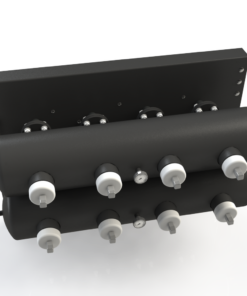

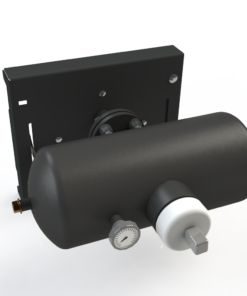

The pneumatic cleaning system for 100-150 kW boilers solves this problem by automating the cleaning process. Using high-pressure compressed air, the system effectively removes ash deposits from heat exchangers and boiler walls, providing cleaning without stopping the equipment. This allows to significantly reduce the frequency of labor-intensive maintenance sessions and simplify the cleaning process. The FOCUS system automatically performs cleaning at pre-set intervals, maintaining a high level of boiler efficiency and minimizing the need for manual cleaning.

Boiler pneumatic cleaning system:

Maintains high boiler efficiency by effectively removing combustion products from heat exchange surfaces. Ensures uninterrupted operation of equipment, which is especially important at low temperatures. Removes deposits from key structural elements and the combustion chamber, maintaining optimal operating conditions. Reduces the need for manual cleaning, simplifying the maintenance process.

The pneumatic cleaning system for 100-150 kW boilers significantly increases the intervals between cleanings and minimizes the need for manual labor. It is ideal for both FOCUS solid fuel boilers and boilers from other manufacturers.

This system is an excellent solution for small industrial boiler houses, it can be installed on any boilers and ensures reliable operation.

Reviews

There are no reviews yet.