Climate control for unregulated heating of individual rooms

Not only most households, but also farm greenhouses and industries use unregulated heating; today we will discuss climate control with unregulated heating.

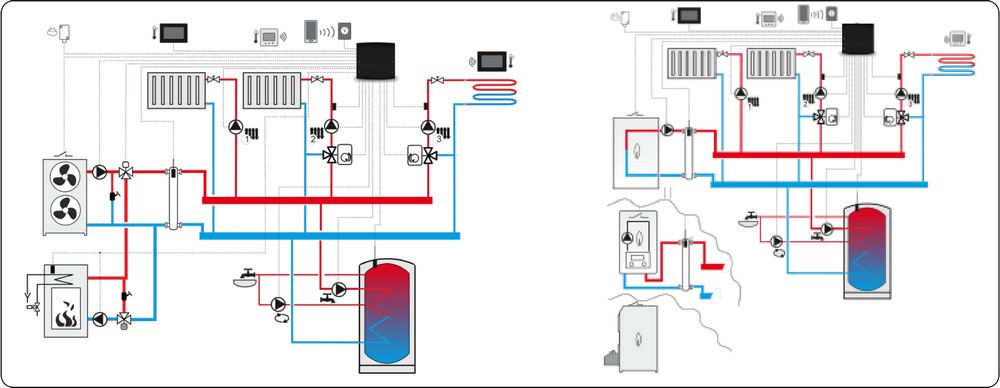

We are talking about heating one or more heating circuits with a boiler with minimal automation. Air heating has become an alternative for farm greenhouses in such conditions, since gaseous substances are distributed more quickly and the microclimate can be satisfactorily regulated. But now you can use climate control with minimal automation of unregulated heating circuits.

Climate control in systems with solid fuel boiler

Typically, unregulated systems include heating circuits heated from stoves, fireplaces or simple solid fuel boilers. Depending on the operation of the pump or in its absence, the batteries in such circuits may heat up with varying degrees of intensity. Accordingly, near the boiler or stove the heating radiator will be hot, and in the far room it will be much cooler. Thermally insulated containers, in other words, heat accumulators, can even out temperatures and, at the same time, ensure savings and heating of premises during periods of no heating.

Climate control with unregulated heating has the followingThe principle of operation and temperature regulation in such systems is as follows:

- a solid fuel heat source heats the coolant in the heat accumulator;

- the coolant from the heat accumulator can heat secondary circuits, including the heated floor and hot water circuits, or is distributed along the heating circuit, where it moves at different speeds;

- Using a pump and a coolant temperature sensor, you can regulate the temperature in the room. However, for these purposes a controller will be required that will compare the performance of the coolant in the room, and not just respond to changes in the characteristics of the coolant;

- end consumers, that is, radiators, can be equipped with digital or analogue thermal valves, in some cases with room temperature sensors. The principle of their operation is to regulate the rate of passage of coolant through the batteries. The presence of radiator valves implies certain rules for the design of the heating circuit.

This option allows you to really automate the operation of a solid fuel boiler and supply heat evenly in the room.

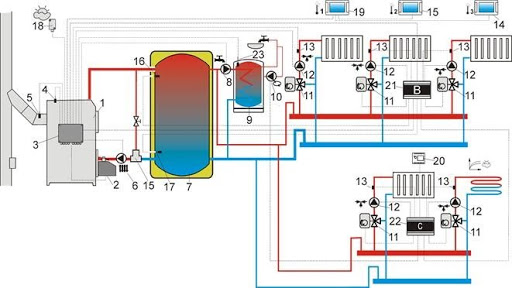

Heat accumulators can also be used for adjustable circuits, primarily for organizing hydraulic isolation for connecting heated floors. This system is also more preferable for boilers with pellet burners, which retain the backup option of manually loading firewood. The connection diagram suggested below will work successfully in both modes.

An elementary connection diagram with a thermal buffer of a pellet boiler with the possibility of expanding the capabilities of the heating system without a significant increase in cost due to automation will look as shown in the figure. The thermal buffer allows you to connect additional heating circuits and heated floors to the system with minimal automation costs. This is the most suitable solution for residential building owners who are gradually renovating and want to connect heated floors and backup heating circuits with radiators in the future, but do not want to greatly increase the heating automation budget.

Climate control in unregulated circuits in apartments

The deployment of climate control in apartments should be carried out together with the installation of a heating metering system. This is implemented in two ways. Using thermal valves on radiators and/or using a microcontroller, including limiting the heat supply at the input. Such a system allows you to take into account the supplied heat in the apartment, distribute it and regulate the temperature in the rooms. Climate control with unregulated heating in an apartment has its own characteristics, which is not connected to the heating boiler. But you can install an additional electric boiler, which will be turned on as needed using the climate control system.

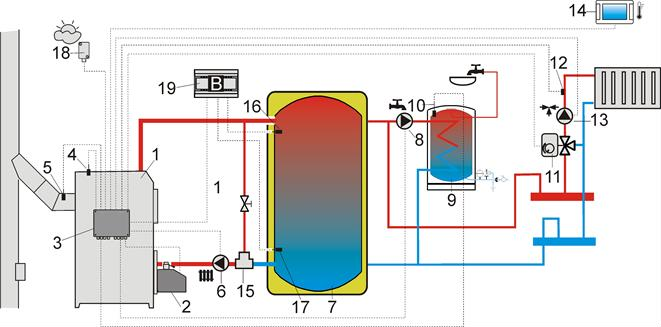

Climate control with program-controlled boilers

It is difficult to control the operation of a solid fuel boiler in all cases except for the pellet version. In this case, it is possible to regulate the supply of fuel, oxygen and secondary air, maintaining the combustion parameters of the boiler. This is implemented using the boiler microcontroller. The climate control system is connected using an expansion module, which, together with the touch panel, controls the thermostatic sensors. Such a system can be accessed using a mobile application and website.