Automatic burner with flame control and self-cleaning - features of operation

Pellet burner with flame control is the basis of an automatic heating system. Its functionality is that due to the installed fan or the movement of the rotary furnace, the flame becomes less or more intense. This is done using an air supply system. Additionally, such systems have the ability to clean the furnace from ash and soot, which intensively arise after using high ash fuel.

How the flame control burner works

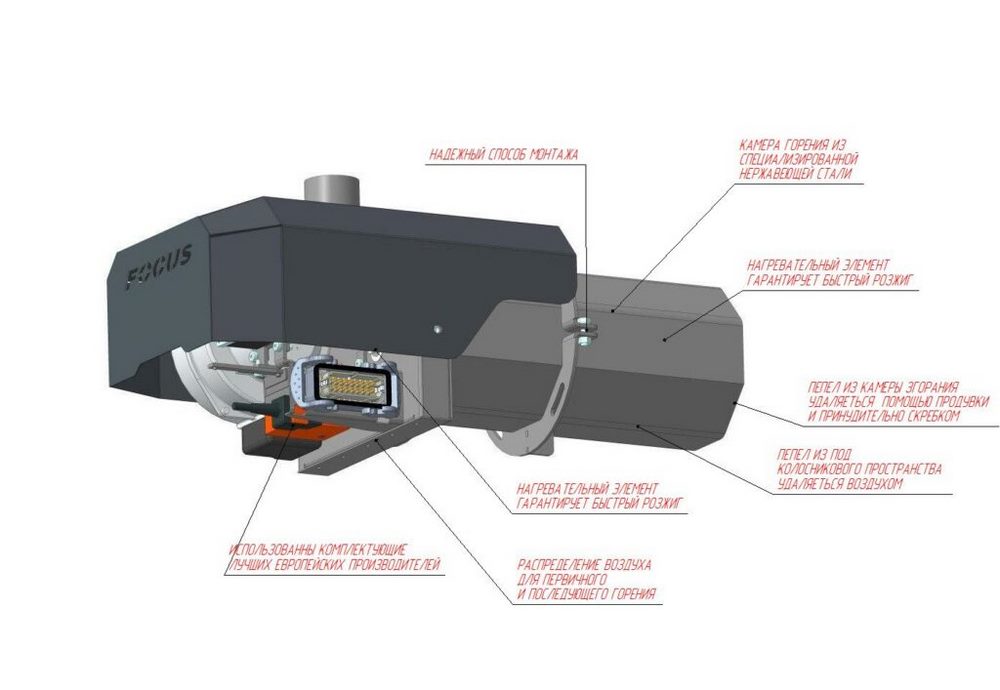

Automatic burner with flame control has a heating element on board, from which the pellets are ignited in the combustion chamber. To maintain the effect of volumetric combustion, air is supplied throughout the entire volume of the furnace, due to which the pellets burn intensively and generate heat.

In this case, the intensity of combustion is maintained by air, a fan or a rotary air chamber with nozzles. We talked about it in one of our publications. Air supply throughout the entire internal volume of the burner. This also provides pyrolysis afterburning of gases, that is, secondary combustion products. As you can see, the well-established principle of an ecological approach is used in pellet boilers. It consists in the fact that the heating devices work without waste. This is done with a pellet flare burner.

Cleaning system in automatic pellet burner

One of the most important functions of a pellet burner is its self-cleaning. Most of the pellet flare burners implement one of the functional cleaning principles. For example, mechanical or pneumatic with a compressor. The option with mechanical cleaning and ash catcher is considered the best. The operation of the sensor depends on the readings of the sensor of the quality characteristics of the fuel raw material. Such a device is the first step towards automation of heating.

These possibilities complement the functions of the automatic pellet burner, so its operation becomes more comfortable and justified.