heating equipment

FOCUS TERMO

With a love of engineering

— LATEST NEWS —

FOCUS TERMO heating equipment is a unique combination of engineering ingenuity, science and manual assembly, thanks to which it is possible to obtain boiler models that are significantly superior in technological innovation to the offerings of competitors. We invite you to familiarize yourself with the latest news.

First of all, this is premium-class heating equipment designed for autonomous heating of large and small classes: from medium-sized residential buildings to large cluster boiler houses that provide urban buildings with central heating. We offer you a comprehensive overview of our heating equipment, which will help solve various problems of delivering inexpensive heat.

Our company is working on the deployment of heating equipment and autonomous boiler houses of various sizes. One of the concepts is cluster city boiler houses operating on waste pellets, which provide heat supply within a small city cluster and do not require labor-intensive maintenance.

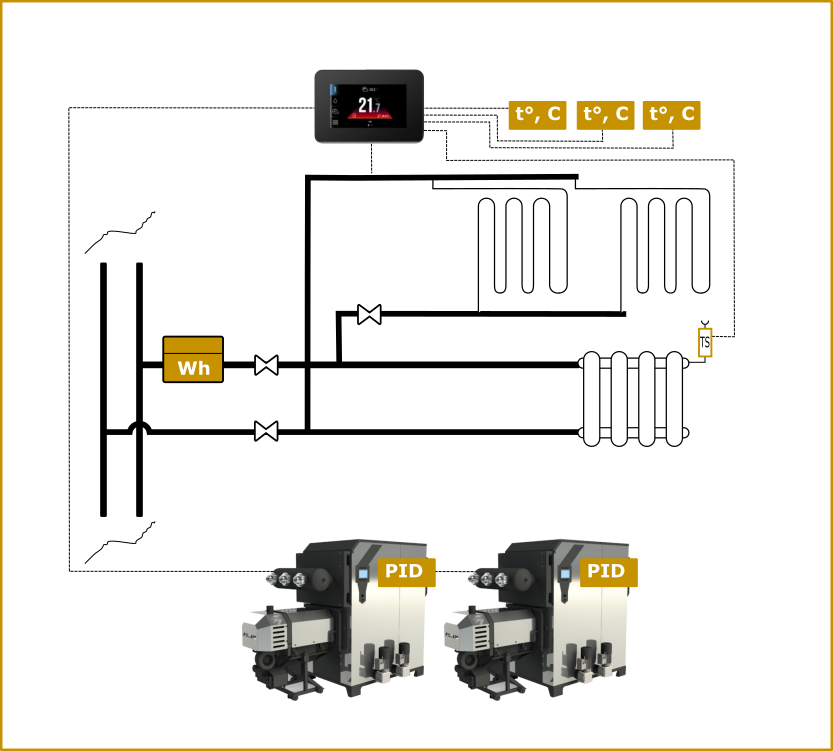

FOCUS pellet boiler houses, operating on the basis of PLUM microcontrollers, make it possible to supply heat to apartments “on demand” throughout the year, significantly optimizing consumption in winter due to a weather algorithm based on scenarios. The boiler room can be supplemented with climate control, which is installed in houses along with the installation of heating equipment and heating wiring.

— Your path to savings while improving your comfort level —

FOCUS boilers are a technological innovation on the market, combining compliance with environmental requirements and maximum boiler power for the selected parameters.

Sectional view of the FOCUS self-cleaning boiler.

In central or individual heating with year-round heat supply “on demand”, an optional feature is climate control, carried out together with the heating distribution, fully interacting with the heating equipment.

Autonomous FOCUS pellet boiler rooms are controlled by a PLUM microcontroller, which regulates the operation of the boiler in accordance with the user settings in the premises. Climate control devices are available in wired and wireless versions.

Pick up a modelThe boiler body is made of polished stainless steel, which makes this equipment extremely impressive in appearance.

An autonomous boiler room can operate on pellets, even those made from waste. We recommend using agro granules with ash content 10%.

Thanks to the almost complete combustion of flue gases and the use of an ash filter, the complexity of cleaning the boiler is reduced.

If you purchase a self-cleaning FOCUS pellet boiler with a screw ash removal system into rollaway containers, such equipment requires almost no maintenance and operates in a fully automatic mode. This is an autonomous boiler room that can be installed to heat multi-storey buildings.

You can form heating clusters far from the city, supply cottage villages and hotels with heat without any maintenance. Such a boiler room regulates its operation automatically.

Autonomous boiler rooms FOCUS with cascade connection guarantee continuous heat supply even when one of the heating units is turned off. This is convenient and profitable, especially when making pellets from city waste, which reduces the pressure on nature. The products are used in greenhouses (CO2) and in the production of high-strength concrete (ash).

Pellet boiler houses can be used in individual and central heating, regulating the heating of the coolant and the operation of heating devices in accordance with weather conditions. This is significantly more profitable than using gas equipment.

Our technology makes it possible to form city clusters with independent heating connected to Smart City, to the digital layer of smart heating of megacities, which are heated by pellets and generate electricity also from city waste.

The installation of individual heating for heating rooms is not required in such solutions, and these systems are also effective in apartment heating, air heating, the use of water heated floors, heating small residential buildings and other solutions with low fuel consumption.

— SMART CITY —

Heating with pellets from waste

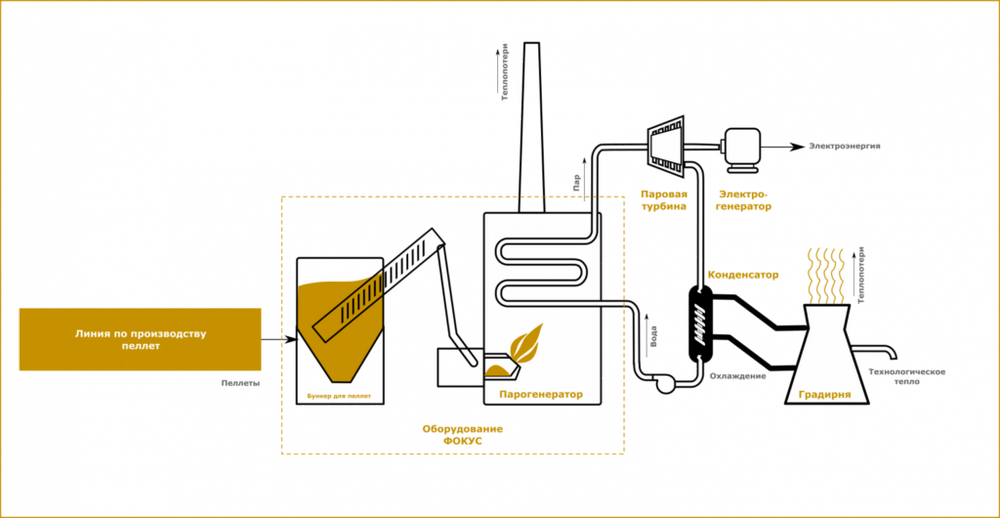

The city's thermal power plant, powered by pellets made from waste and garbage, generates electricity using a FOCUS steam generator, and the by-product is heat. It is used for hot water supply and heating, implementing the concept of independent heating.

Although pellet technology makes it possible to create stations with a conditionally unlimited power, the overhead costs associated with transporting heat from autonomous boiler houses to consumers still require the creation of cluster or individual thermal power plants using pellets.

This selective option for central heating supply is good because the heating equipment does not affect the natural environment (the smoke coming out of the chimney is cold and does not contain harmful impurities such as CO2 and fumarates). This is realized using pyrolysis technology and CO2 filtration for subsequent use in greenhouses.

Heating distribution across climate control rooms allows end users to control the operating power of the heating circuit and use heating “on demand”. At the same time, the thermal TPP supplies electricity using city waste as an energy resource.

— SMART CITY —

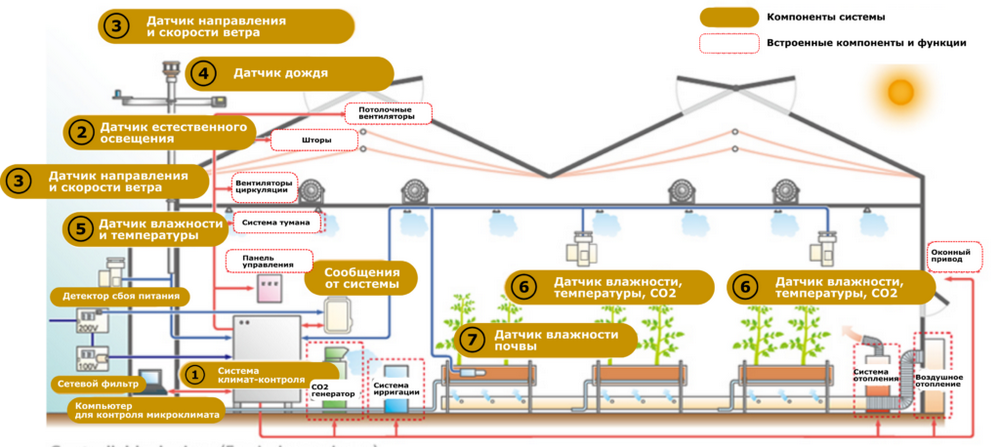

The climate system of a greenhouse is a closed cycle of periodic processes of heating, air conditioning, spraying, and fogging. These measures are aimed at temperature correction in combination with light regulation.

A feature of any TT heating is the emission of combustion products and CO2. Some of them undergo a pyrolysis cycle as fumarates; CO2 can be recycled in the greenhouse to improve plant growth.

FOCUS pellet heating for greenhouses is represented by the HVAC concept. It involves heating the room through three adjustable circuits - air, water radiator heating and water heated floors.

Since any greenhouse is a quickly cooling structure, air heating is most effective. However, heated floors and radiators play an important role in the temperature balance and regulate the activity of an autonomous boiler room.

— SMART CITY —

An autonomous boiler room for greenhouses provides independent heating at a low price and with a climate control system. The boilers in such a heating point are connected in cascade and each additional heating equipment is connected when increasing power.

This makes it possible, with the help of climate control, to supply heat “on demand” to heat the room throughout the year, but with significant savings. PLUM automation ensures regulation of the boiler operation in accordance with the weather sensor, scenario and settings.

Compared to gas equipment, pellet heating is much cheaper. The boiler room can supply heat to the apartment riser without limiting users in the number and types of heating equipment. In addition to connecting radiators, it is permissible to install warm floors and air heating.

The operation of user devices can be controlled using a touch panel that transmits data directly to the microcontroller of the operating boiler.