Hot water as a heat carrier for a solid fuel boiler and options

The topic of choosing a coolant for a heating system is very relevant. The most optimal and most commonly used is hot water. Most heat consumers stop at it because of its simplicity and economy. However, an alternative coolant for a solid fuel boiler has a number of advantages. Keep in mind that water is significantly inferior to steam in terms of heat transfer and is used primarily for low-power or domestic heating systems, including pellet boilers FOCUS. If heat is required on an industrial scale, it is produced at CHP plants using steam generators.

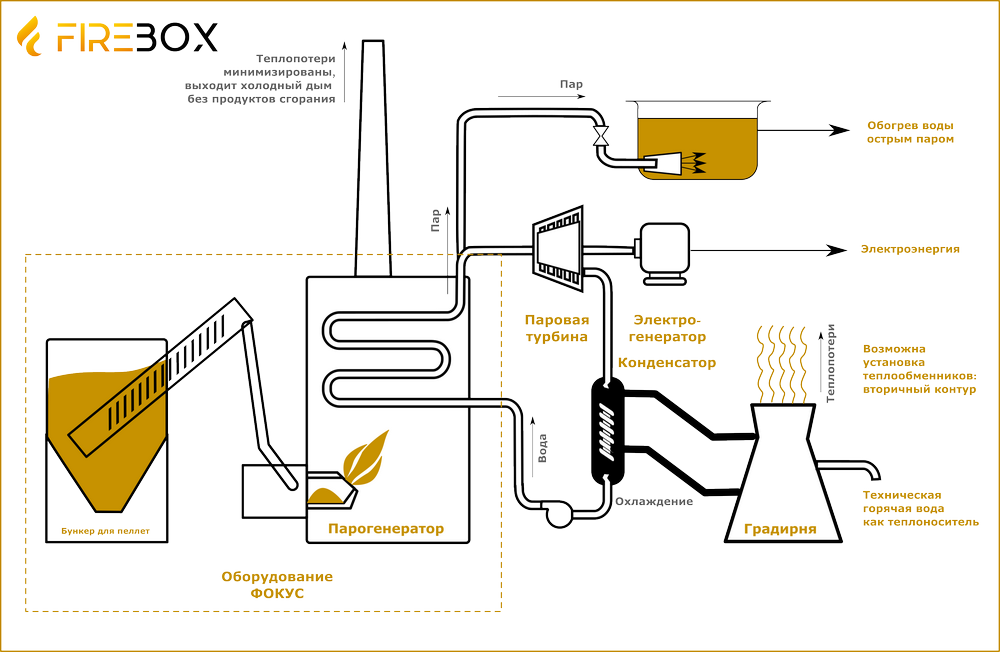

The advantage of steam over water is not only in thermal power and efficiency. The main purpose of steam is to generate electricity. The surplus, as well as process hot water from the heat generating turbine, is used for heating.

What coolants are there besides steam and hot water?

There are a number of types of coolants that compensate for the lack of water. First of all, water freezes, which is a significant limitation of its use in systems installed in potentially unheated rooms. There is a possibility of pipe rupture.

Water is a corrosive agent, heat carriers on a different basis do not have this drawback, they do not freeze up to about -30 to -40 ° C. A significant advantage of alternative heat transfer fluids in terms of thermal capacity is the retention of heat by about 25% more than that of water.

So, if you know you'll be leaving your house unattended, are trying to conserve pipes, and want to improve system efficiency, use glycerine and propylene glycol-based heating fluids. If you are using buffer capacity for a solid fuel boiler, there are no restrictions on the use of alternative heat exchange fluids.

Water is the preferred heat carrier for a solid fuel boiler due to its budget. If you are experiencing financial difficulties and do not want additional hassle, opt for hot water without water treatment. Make no mistake!

What and how to heat???

Most people stop at water as a "folk" coolant for a solid fuel boiler. It is shareware, available in unlimited quantity. The heating system can be freely connected to the water supply and with valves control the filling of radiators with water automatically. However, water is used for radiator heating and floor heating.

These systems, in combination, heat the room very efficiently, but the installation of such heating is quite expensive. The wiring of the high-temperature circuit is carried out with the help of collectors, sometimes with the admixture of cold water using three- and four-way valves.

hot water heated by live steam.

In other words, any heating with a heat carrier for solid fuel boilers with water is low-power. For frame houses, it is better to use air heating, and it is most efficient to heat the air with steam produced by the FOCUS steam generator, but this is only possible with village heating. Steam boilers are more efficient and more suitable for utilities that also use water as a secondary heating medium, so as not to complicate consumers to connect to the system.

FOCUS steam generator in combination with microturbines can be used to generate electricity. In this case, ceramic heaters can be used for heating, as well as underfloor heating and warm walls, based on a carbon heating cable. This heating option is suitable for houses made of foam concrete, brick, concrete, and is relatively acceptable, although inefficient, in frame houses with large heat losses.

Hot water preparation: heating medium for solid fuel boiler FOCUS

Hot water as a heating agent is not very effective due to the lower heat transfer coefficient than that of condensing steam. In addition, the water temperature decreases along the surface of the heat exchange wall, which affects the uniformity of heating.

Hot water as a heat carrier is obtained in a boiler, where it is heated by flue gases resulting from the combustion of pellets in a pellet burner. Water is heated up to a temperature of no more than 100 °C.

Flue and flue gases are often used as a heat source. Their operating temperature reaches 1000-1100°С, the heat transfer to the coolant is quite small, therefore, the secondary supply of flue gases to the furnace is implemented in FOCUS boilers. As a result, steam with a lower temperature and a small amount of impurities is released into the atmosphere.

The availability of a heat source is offset by a number of disadvantages:

- uneven heating;

- limited possibilities for regulating the heating temperature;

- low heat transfer between gas-water media.

The temperature difference creates harsh operating conditions, which may be unacceptable for the elements of the system.

It should be taken into account that the flue gases cannot be transported, so the thermal energy is taken directly in the furnace with the help of a heat exchanger, the heat transfer of which will depend on the size of the working surface. Flue gases rise up, where they transfer their heat through the heat exchanger wall to the coolant by convection. Additional heat exchange devices help to improve the heat extraction of gases and raise the temperature of the water with a small fuel consumption. Water as a heat carrier for a solid fuel boiler completely solves the problem of heating.

The heating temperature is controlled by recirculation of produced and used gases. It is provided by smoke exhausters, which return part of the gases to the boiler furnace. An increase in the volume of gases leads to an increase in the velocity of the coolant and, accordingly, to an increase in heat transfer to the contact wall. The fuel consumption for hot water treatment when filling the radiator circuit is determined from the heat balance equation. In this case, the standard calculation approach takes into account heat losses from underburning of flue gases. In practice, this issue is solved by flue gas recirculation.

Thus, hot water is the optimal natural heat carrier, the quality of which is not impaired by restrictions on use. The improvement of heat transfer in FOCUS boilers is realized with the help of flue gas recirculation.

Familiarize yourself with the types and designs heat exchangers.