Heating with steam and steam generator: the most efficient heat transfer medium for heating systems

The choice of heating agent for heating systems is an important criterion for heat transfer efficiency. Water vapor as a heat carrier for heating systems is widely used in industrial facilities and for heating the municipal system. Steam condensation makes it possible to obtain large amounts of heat at a relatively economical steam consumption, since the heat of condensation at a pressure of 1 atmosphere reaches 540 kcal / kg.

Due to the high heat transfer coefficients from condensed steam, the resistance to thermal energy transfer is relatively small, which makes it possible to provide heating with a small heat exchange surface.

Water vapor is an effective heat carrier for utility heating systems, its features

Steam generators and, accordingly, water vapor is actively used by utilities for heating apartment buildings, because it is profitable. The benefits lie in the properties of saturated steam. First of all, its important advantage is the constancy of the condensation temperature at a certain pressure. This allows you to keep the heating temperature, knowingly adjusting the temperature when the coolant for heating systems is heated, as well as making corrections by varying the pressure of hot steam.

The efficiency of steam heating installations is one of the highest, and other requirements such as accessibility and fire safety are also met.

The disadvantages include a directly proportional increase in pressure with increasing temperature. As a result, the heating temperature with which the coolant for heating systems comes into contact usually does not exceed 180-190 ° C, which corresponds to a vapor pressure of about 10-12 atmospheres. If you want to use higher temperatures in heating, there is a threat of a steam explosion, so unprofitable thick-walled heat exchange units are required, which are manufactured by manufacturers on special orders and have a very high price. The same high requirements are placed on communications and the shut-off valves used.

Pellet steam generators

This solution is ideal for cluster heating and power generation, using pellets from urban waste for these purposes.

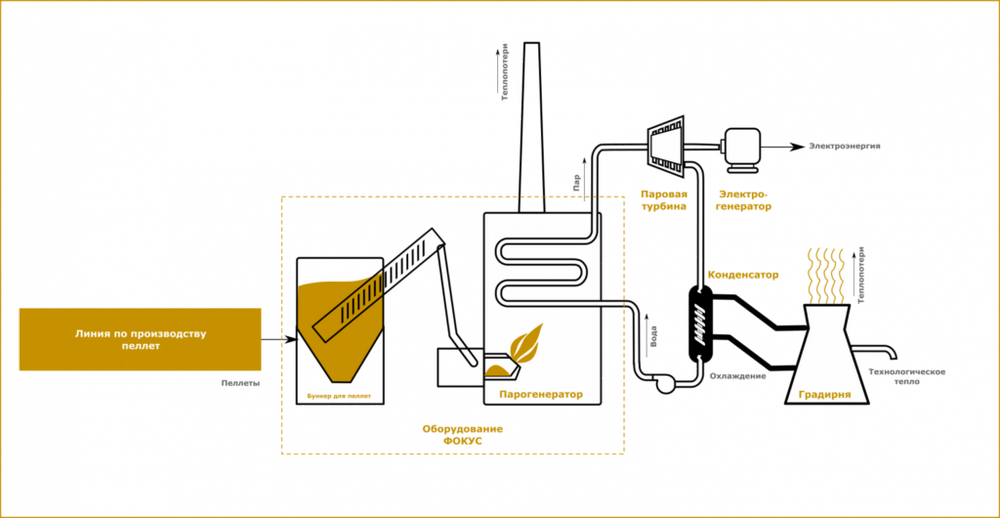

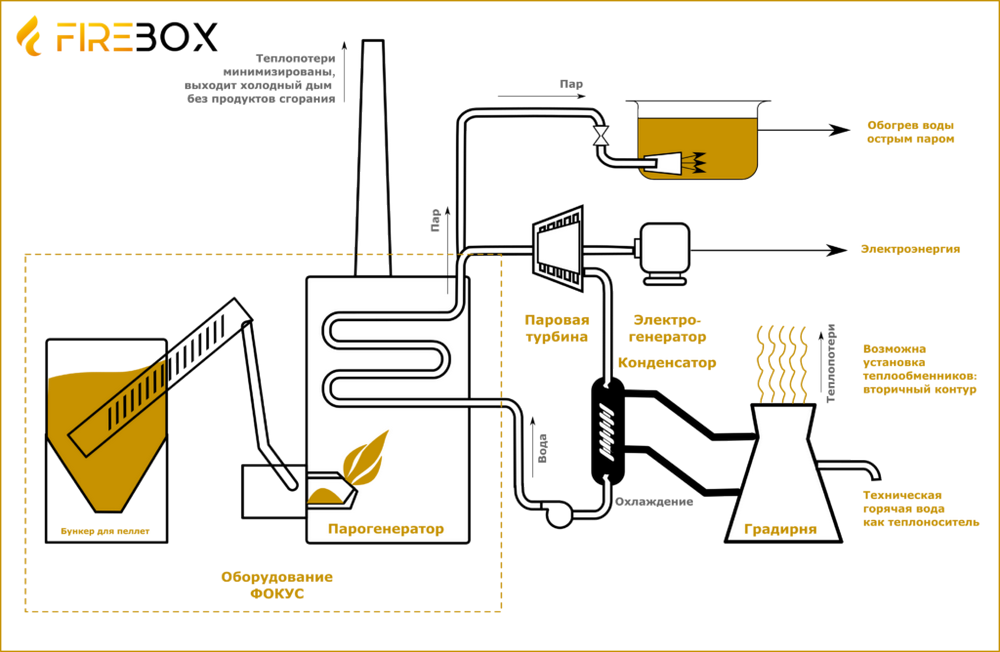

In the conditions of municipal enterprises, heating with steam is possible when using the steam generating unit TM "Focus". steam generator FOCUS can be used as a steam boiler module providing steam preparation using pellets. This is a highly efficient independent heating technology with high heat output, ideal for municipalities. The steam generator for a steam boiler room can be combined with a pellet production line from any suitable raw material. Taken together, such a production approach can significantly reduce heating costs or sell heat to the population with a large margin.

Utilization of industrial steam

In industrial cities, enterprises can utilize water vapor, which remains unused after steam power plants. First of all, in chemical industries. Recycled steam, as a rule, has a pressure of up to 250 atmospheres. It is redirected to turbines to generate electricity, and the already exhausted steam after turbines with a pressure of 6-8 atmospheres is used for heating. However, the features of the recycling technology require structural improvements.

In particular, the resulting "crumpled steam" is overheated, and pipelines with an increased diameter are required for its transportation. To avoid the need to transport the steam under special conditions, it is humidified by adding hot water. In this condensed state, the steam is sent to heat exchangers. However, in professional systems, "crumpled steam" is rarely used for the heat carrier of heating systems, since the heat transfer coefficients of superheated steam are much lower, but it is used to maintain the temperature of the coolant and compensate for heat losses.

Heating of the heat carrier for heating systems "dead steam"

The heat exchanger for deaf steam implies the transfer of heat through the wall. The principle of operation implies that steam from the steam generator is supplied to the heat exchanger, where the coolant (liquid or gas) is heated by steam through the contact wall. The steam, when in contact with the cold wall, obviously condenses and is discharged at the bottom heat exchanger. The temperature of the condensate film and the condensing vapor is approximately the same.

The consumption of deaf steam required for the coolant of heating systems, when steam is heated without interruption, is determined by the heat balance equation. To do this, you need to know the heat capacity of the medium, the temperature range, the enthalpy of steam and condensate, as well as heat loss.

The reduction in performance of such a steam heat exchanger is reduced if the steam does not fully condense on the walls. Condensate drains are used to remove condensate, condensed water is fed back to the steam generator. Condensate traps with a float are used at pressures up to 10 atmospheres.

Steam traps are installed under the heat exchanger and are provided with a bypass line, which allows you not to turn off the unit during repairs.

Removal of non-condensable gases

The heating steam contains a small amount of gases that do not condense under operating conditions. We are talking about (N2 O2) CO2), which is released during the chemical treatment of the boiler liquid and as a result of vaporization. This impurity significantly reduces heat transfer. For this reason, these gases are removed; for these purposes, a purge valve is used in the steam trap.

Heating of the heat carrier for heating systems "live steam"

This method of heating the coolant is much simpler and involves the introduction of steam directly into the coolant liquid. In other words, it is carried out by mixing the heated medium.

Steam is introduced through bubblers. These are pipes placed at the bottom of the mixing tank with an end cap with many holes. This is necessary to improve mixing conditions and reduce noise, as well as eliminate possible water hammer.

Silent heaters have a nozzle through which steam is issued. The liquid from the tank is captured through the side holes, mixed with steam, so the coolant for heating systems is heated. The consumption of live steam is also determined from the heat balance equation, taking into account the equality of the final temperatures of the liquid and condensate.

Design of steam boilers for houses, OSBB and industry

If you want to buy a steam generator and use water vapor as a heat carrier for heating systems not only as efficiently as possible, but also to make it maintenance-free and automatic, choose FOCUS pellet steam generators for heating. Our experts will help with the development of an individual steam boiler project for your goals and objectives. The advantage of pellet technology is the automatic supply of pellets from a bunker or storage room. FOCUS steam generators are equipped with a microcontroller for program control of heating equipment. Steam heat exchangers are manufactured by a Swedish company ALFA LAVAL, which is presented on the Ukrainian market.