Pellet burners FOCUS and boilers

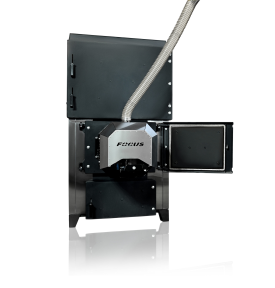

If you want to use pellets for heating, but there is no suitable heating equipment, you can buy pellet burner flare type FOCUS for any solid fuel, diesel and gas boilers.

FOCUS pellet burners are a simple, reliable factory-assembled solution that will allow you to use pellet fuel with high efficiency, without regard to its ash content, and is also environmentally friendly.

Do you want to buy a pellet boiler?

Pellet boiler FOCUS is a universal program-controlled solid fuel heating unit with a FOCUS pellet burner installed in the boiler door, which can be used in any heating mode, depending on the availability of fuel.

LookModel range "FOCUS"

Solid fuel boilers

Gas generating or pyrolysis boilers designed to burn low-cost fuels with high efficiency. They are classified as long-burning equipment.

FurtherPellet burners FOCUS

FOCUS heating equipment helps to convert boilers to pellets with low installation costs and receive inexpensive heat without gas.

FurtherBoilers for pellet burners

Specialized heating equipment for pellet burners allows you to set up automatic operation of a boiler with a power of up to 2.2 MW

FurtherPellet boilers

Solid fuel boilers of industrial type with an external "parked" pellet burner at the door with a total power of 2.2 MW.

FurtherFittings and electronics

Components and electronics provide automatic operation of boiler rooms and supply of heat carrier on demand with a given temperature.

FurtherFogging systems

Needed to create a microclimate with a stable controlled temperature in the outdoor territory of households, in greenhouses, parks and city streets.

FurtherPellet steam generators

FOCUS steam pellet boilers are highly efficient and are designed to produce steam and meet technological production needs.

FurtherSelf-cleaning pellet boilers

FOCUS pellet boilers with built-in self-cleaning system. The model range is divided into two types of systems.

FurtherComponents for boilers, climate and fogging systems

Ukrainian-made pellet equipment involves the deployment of installations for space heating from individual modules and components.

FurtherConvert production to pellets

If you want to buy a pellet boiler designed for all types of pellets, including high-ash ones made from sunflower husks and lignin, choose the FOCUS solid fuel boiler with a door adapter for a torch pellet burner in a collapsible form factor.

Pellet fuel - #1 worldwide

Install the burner and boiler,

powered by bio and wood pellets:

Many types of fuel cannot compete with wood pellets in terms of environmental and cost characteristics, but the replacement of heating equipment remains a limitation to the use of renewable fuel raw materials. Buying FOCUS pellet burners, you can convert any type of boiler, gas, diesel, solid fuel, without making structural changes to the heating equipment and heating system.

You can buy pellet burners complete with solid fuel boiler FOCUS, having a door adapter for quick installation and use of the boiler room in two modes, heating the premises with wood or pellets, depending on the availability of the energy resource.

FOCUS pellet boilers are adapted to work with high-ash granules from sunflower husks and lignin.

They are undemanding to the quality of granules. Provide complete combustion of pellets due to volumetric combustion. And they are already used in Ukraine for heating residential, administrative premises and industries to obtain inexpensive heat without gas.

Significant savings will be a pleasant bonus for buyers, since a minimum amount of raw materials is required to achieve a high coolant temperature. Significantly less than for the boiler furnace with solid fuel. Savings compared to gas today is at least 50% per kilowatt of energy.

FOCUS offers high quality pellet burners at competitive prices, which will be a good help to owners of houses, farms and geographically remote industries.

Air heating

Pellet burner FOCUS can be set to work with simultaneous heating of water and air coolant. This approach increases the overall efficiency and reduces heating costs.

Water heating

When using the classic water heating of a private house, the power of the boiler with a pellet adapter allows heating several heating circuits with the same efficiency.

Steam heating

Any FOCUS pellet burner can successfully work with a steam boiler, reducing the cost of heating a private house by several times. The solution is often used in frame housing construction.

Get our offer!

FOCUS pellet burners can be purchased complete with solid fuel boiler FOCUSwith a door adapter for fast installation.

Solid fuel boiler with burner door adapter

Advantages:

Pellet burners FOCUS flare type

Peculiarities:

The installation of a pellet burner does not require replacement of heating boilers. This requires a burner and a hopper with a pellet feeder.

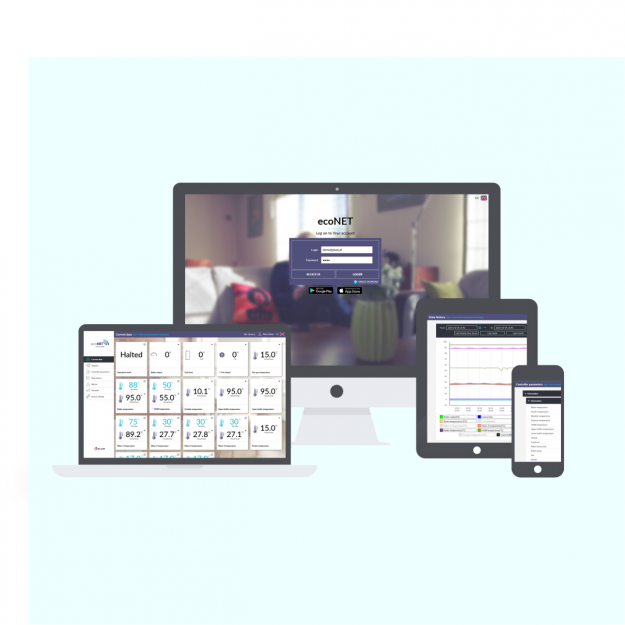

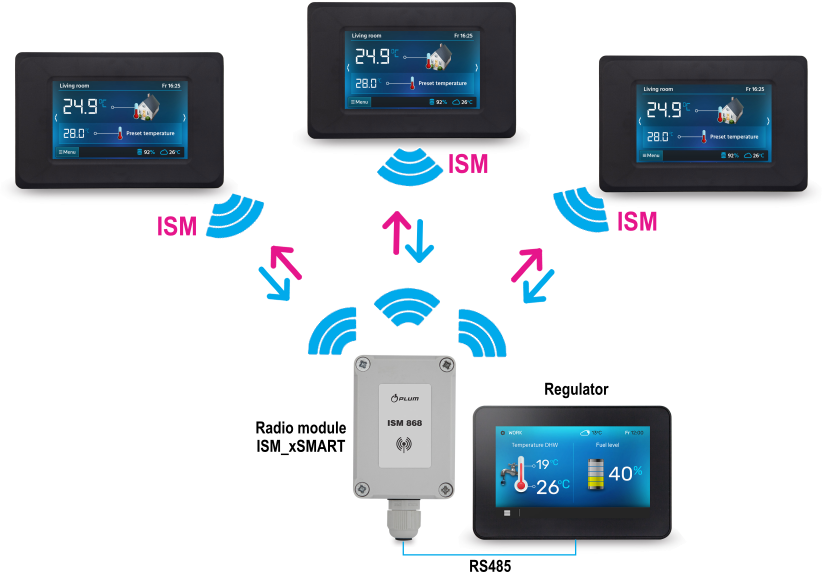

Automatic ignition: the process is controlled by a controller connected to a control panel and sensors.

Automatic pellet feeder from the bunker, the volume of which can be selected based on the needs.

High efficiency among heating boilers of other manufacturers as a result of burning pellets of a flare type.

The burner is equipped with automatic cleaning of soot formed during the combustion of pellets. Pellet burners are completely autonomous.

Convenient control panel with information about the operation of the boiler and the state of the system.

Adjustable power of the burner depending on the needs and the condition of the sensors.

Working since 2010

FireBox sells heating boilers of its own production, devoid of the disadvantages of burning pellets, which are typical for foreign models. First of all, flare pellet burners provide the process of burning pellets of any quality, including high-ash, without damage to the equipment.

The set of pellet boilers includes a solid fuel boiler, a FOCUS pellet burner, a pellet hopper, a feeder and electronics that allow the pellet burner to be adjusted to create a comfortable microclimate.

Full production cycle

At its base, FireBox conducts design, assembly and testing standard and individual boiler rooms with automation and options for remote control of equipment.

Microcontroller control guarantees a level of comfort similar to gas heating. But you get cheap heat without gas with a saving of at least 50%, including the use of self-made pellets.

Pellet boilers FOCUS can provide warmth to Off Gride homes.

Design changes can be made to any boiler at the request of the customer.

ContactApplication

Areas of application where FOCUS solid fuel boilers are already successfully operating and provide cheap heat without gas.

Where are we

We adapt the standard design of the boiler house to the requirements of the customer, we sell FOCUS pellet burners and other heating equipment.

Location:

Yuzhnoe Shosse, 1a, Zaporozhye, Ukraine

Get our offer!

If you are interested in FOCUS pellet burners and our other products, but still have questions, please leave your e-mail.

Heating and

water supply

Steam is the most efficient and affordable coolant.

Mini CHP

on pellets

Generate electricity and heat in one technological cycle.

For

industry

Choose FOCUS pellet steam generators for productions.