Pellet burners FOCUS for drum drying

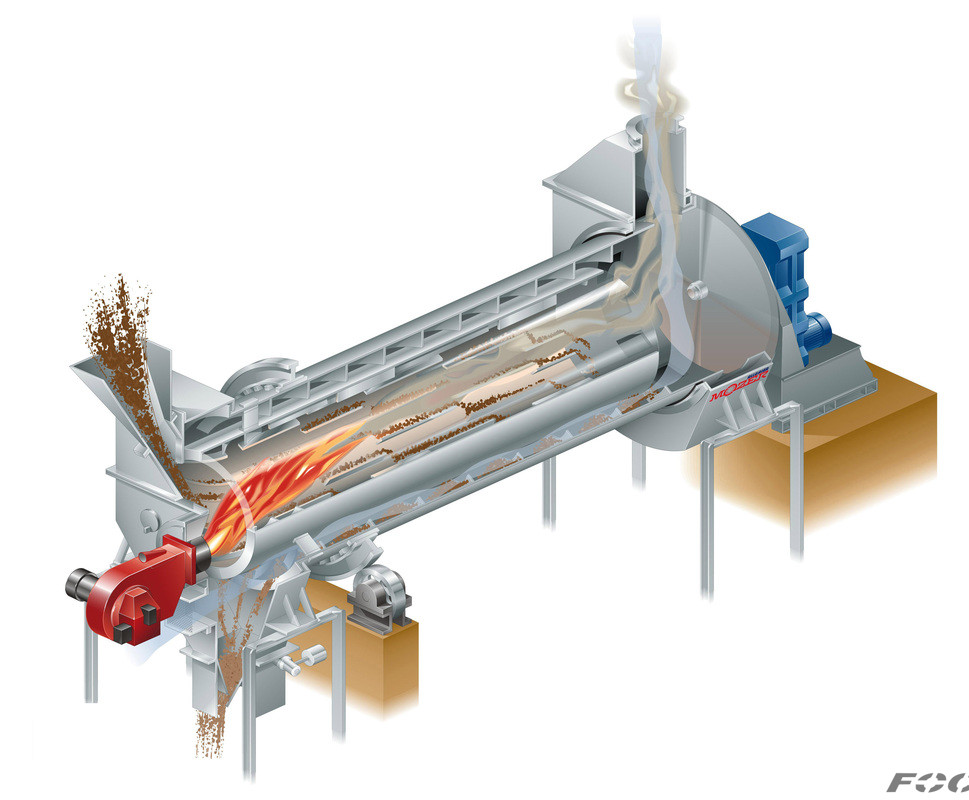

Drum drying technologically implies a method of removing moisture from materials subjected to processing. In industry, this type of preparation is used for building materials. You can even see homemade drum dryers for sand. Drying can be done in different ways, but drum drying is different in the way of removing excess moisture under the influence of elevated temperature and centrifugal forces arising from the rotation of the drum.

Purpose of drum dryers

Dehumidification installations under the influence of aerodynamic rotation and temperature can usually be seen in elevators and factories producing building materials. Usually, they are considered granular, lumpy and bulk materials.

The productivity of the middle class equipment is 150kg-100t per hour. It depends on the size of the drum, loading and unloading chamber. Drum dryer may differ in loading and unloading method, dust cleaning and other production processes. The design assumes the operation of several drying drums, usually three.

In this kind of dryers, the drum rotation speed and the flame rate, that is, the temperature, are usually regulated. Obviously, the power of the dryer is proportional to the loading capacity, but it directly depends not only on the drying performance, but also on the burner power.

The advantage pellet burner FOCUS is the economy on a cheap energy carrier, high combustion intensity with maximum heat transfer and adjustable combustion parameters using a microcontroller Plum EcoMAX... Thus, drum dryers can be adjusted according to a large number of parameters, respectively, it is possible to achieve not only savings, but also the specified moisture content of the processed bulk or granular material.

How a tumble dryer works

Drying of raw materials is carried out in one drum, where it is in constant motion. The drum constantly mixes it under the influence of its own motion and heated air. During drying, not only moisture is reduced, the raw material is crushed and a homogeneous bulk mass with the same moisture index is obtained at the exit.

The drum in such drum dryers moves under the influence of a draft machine. Obviously, the amount of raw materials can vary with the land temperature and the volume of the air-gas mixture. These parameters are ideally provided by the FOCUS pellet burner, which can be adjusted with a minimum step of parameters.

The disadvantage of such equipment is the high operating costs. According to existing standards, 1 ton of raw materials requires up to 20 square meters of heated area of the inner surface of the drum. When using heat-saving metals, the savings reach 15%, but they are not decisive. On average, 1.2-1.3 MW of energy is required per ton of moisture. In this case, only pellet burners that provide 95% efficiency due to volumetric combustion technology can provide a low cost of heat.

Drum dryer: for elevators with FOCUS pellet burners

Drum dryer operating on a pellet burner is a solution to the problem of high energy consumption. First of all, even when using certified pellet fuel, the savings reach 50% per kilowatt. But it can be more if you make your own granules.

For these purposes, small chips from various agricultural waste are used, followed by granulation. Of course, agricultural waste is recycled, but agricultural pellets are one of the most effective secondary resources. The lack of certification in Ukraine contributes to the use of a pellet with varying ash content.

Again, a FOCUS pellet burner with a power of 17 kW to 900 kW can be used specifically for these purposes. The equipment is equipped with vibromechanical ash removal.

Flare burner is more efficient if drum dryer is used

The main raw material of the tumble dryer is hot air, intensively generated by the flare burner. At the same time, the adjustable combustion parameters not only ensure the ignition of the fuel in the entire volume with a high heat capacity, but also provide a large amount of heat. The advantage of such a system is the absence of heat conversion and losses. Hot air from the burner immediately enters the drum, where the production cycle for drying the raw material takes place.

Note that tunable combustion also provides a high environmental friendliness of the process. All combustion products burn with maximum heat transfer and negligible emissions into the atmosphere and ash content.

Why is everything so flare burners FOCUS?

The FOCUS flare burner is the most efficient and cost effective heating equipment in its class. It generates the largest volume of hot air in its class. Due to weldless assembly, the equipment is highly reliable in operation. The burner can be installed in a heating boiler firebox.

At the same time, the following is monitored:

- volume of the firebox;

- the presence of space for the opening of the torch to avoid overheating;

- selection of equipment capacity is carried out, our company produces a wide range of it.

- the presence of vibration cleaning for cleaning from ash.

At the moment, FOCUS pellet burners show the highest efficiency in generating hot air in comparison with analogues. A drum dryer based on them is more efficient, less expensive to operate due to the cost of pellets and the generated heat transfer.