Analog climate control for a heating system with a solid fuel boiler

In understanding technologies "Smart home" climate control is designed to create an individualized environment with ideal climatic characteristics. It is about maintaining the room temperature in accordance with the needs of residents and weather conditions. In a broader sense, climate control also provides air purification and cooling, but we are considering such a complex only in relation to connecting and automating the operation of a solid fuel boiler. This stand-alone solution is suitable for suburban and remote residential buildings and businesses.

The advantages of automating the operation of a heating system with temperature control are not only a higher level of comfort, but also a significant reduction in costs. With proper design, reduction of heat leakage from the room, respectively, fresh air recuperation is truly obtained economical heating.

Features of automation of the heating system with solid fuel boiler

When people who are not familiar with application implementation begin to talk about the “Smart Home” system, they usually mean by this the connection of all home appliances, which ultimately work according to a fabulous algorithm. In practice, everything is rather prosaic, especially for those cases when it is rather difficult to automate the heating process.

Such a case is a solid fuel boiler. The usual design implies manual control of the boiler combustion rate by supplying air to the blower door. More progressive models, among other things, have automatic air supply through nozzles or using a fan. But the regulation of combustion in this case does not allow you to accurately set the temperature of the coolant. For this reason, thermal energy is always released in excess.

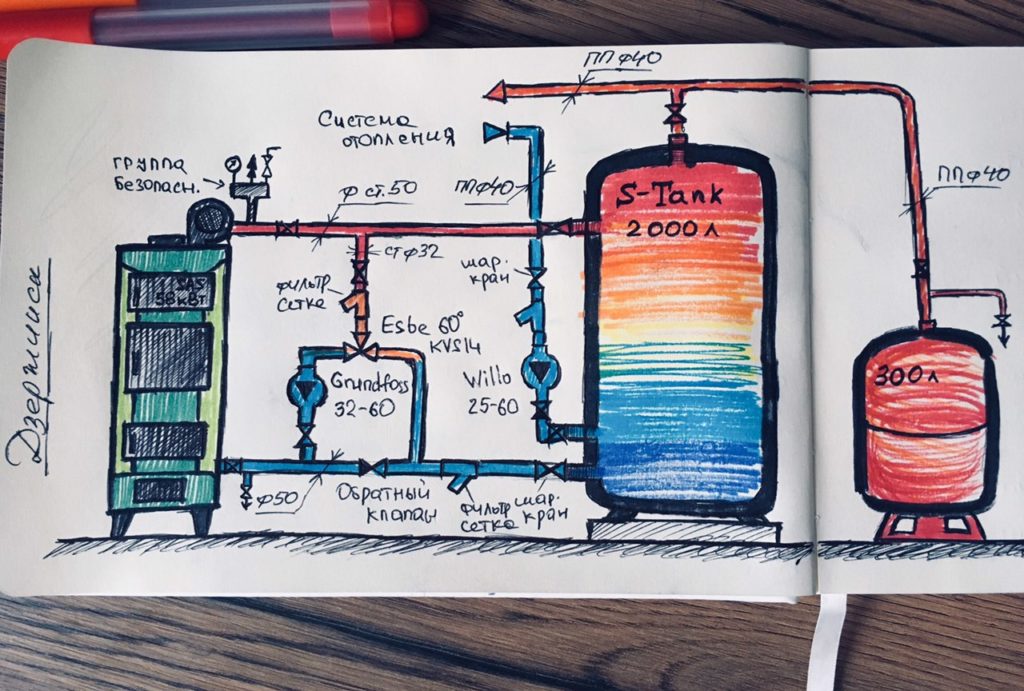

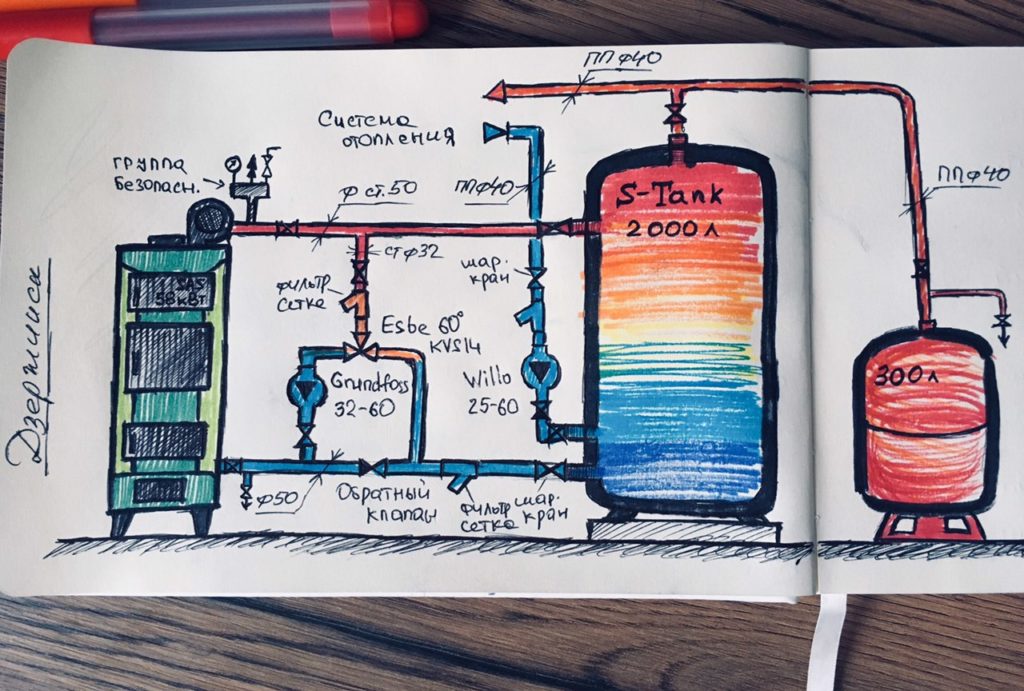

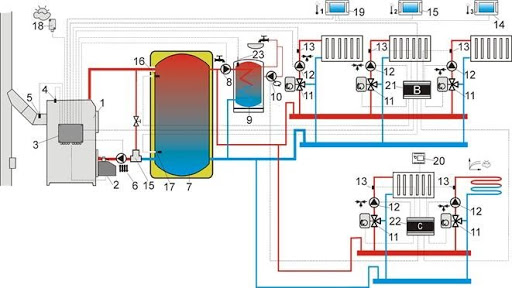

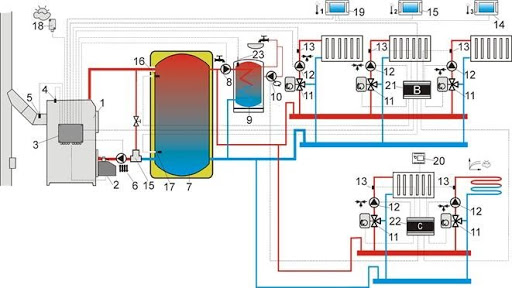

The accumulation of hot coolant in a special tank with thermal insulation significantly improves the functional features of the system. First of all, the presence of several heat exchange circuits makes it possible to organize:

- high temperature heating;

- low temperature heating;

- hot water supply (DHW).

Such a system contributes to:

- extending the overall life of the heating system;

- allows the use of radiators and pipes in the system, designed for temperatures no higher than 90C.

Moreover, thanks to the control system, room thermostats and forced circulation pumps, full automation of heating is provided.

This is a profitable and economical solution, which implies the accumulation of heat energy from a one- or two-time firebox per day and its distribution to end users during the day. To ensure an even supply of heat in such systems, as a rule, an electric boiler is connected as a backup source. It is used to automatically maintain the temperature in rooms during a break in the operation of a solid fuel boiler. In conditions when the house has only electricity, this is how economical heating of a high level of autonomy is realized.

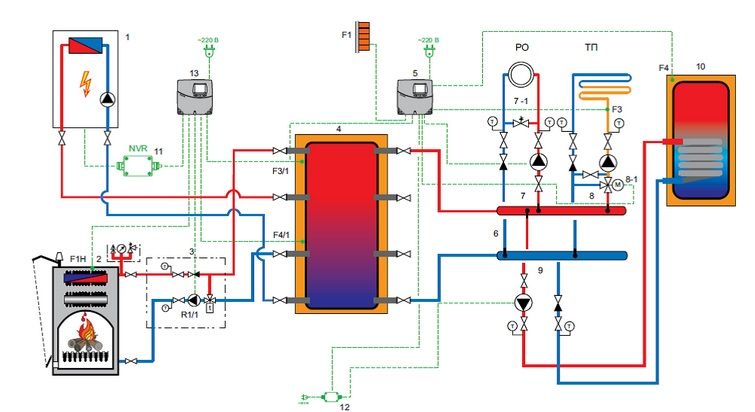

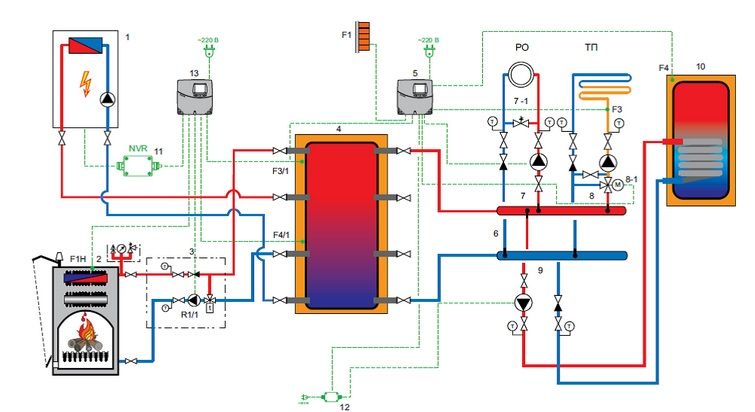

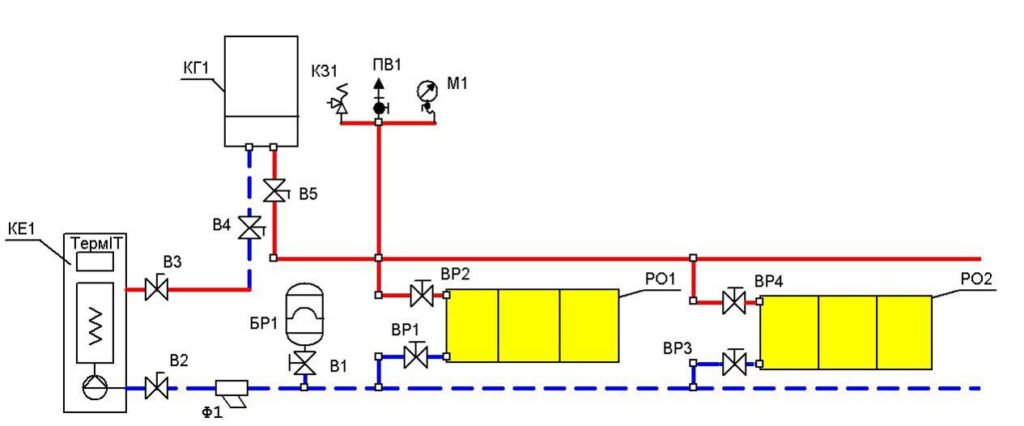

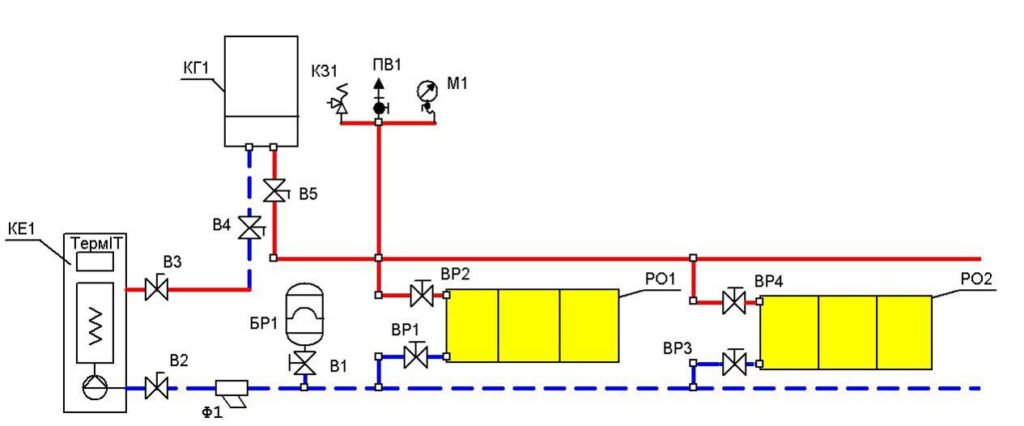

Connection diagram solid fuel boiler with backup heating and climate control

As a result, the connection diagram and boiler piping with an indirect heating boiler and a backup electric boiler is as follows.

Algorithm of the heating system:

- the high temperature primary heating circuit heats the heat exchanger water. For safe operation, it is connected to a safety group, analog sensors that control the pressure in the system;

- for each type of water treatment, its own heating circuit is mounted: hot water supply, underfloor heating, radiators;

- temperature control in batteries and underfloor heating is provided using circulation pumps;

- when the temperature drops below a certain level, an electrode boiler with a monoblock is connected according to the coolant temperature sensor.

A heating system with a heat accumulator allows you to accumulate heat from electric boilers operating at night. In this case, there is no laborious work, but the cost of heating is much higher, although the system meets the requirements of economical heating.

In this case, only analog sensors and devices are used to implement the project. Although the system usually does not support Wi-Fi connections and remote control from a smartphone, it is a complete heating system with climate control.

Are there any alternatives - pellet burners FOCUS and "Smart Home"

The disadvantage of the described solution "Smart House" on the basis of a conventional boiler room, there is a more expensive primary installation and rather impressive dimensions of the boiler room. At the same time, the system requires constant labor-intensive maintenance or the use of a much more expensive heat source. What is the alternative?

This is a pellet burner for 17, 25 or 50 kW, depending on the needs of the household. The device is installed in an existing solid fuel boiler and has a microprogram controller “on board”. With its help, it is possible to control the combustion of the pellet burner and, as a result, the temperature of the coolant.

For the organization of multi-circuit heating and hot water supply, of course, it is possible and necessary to use a heat accumulator and collector connections. But in this case, the transition to pellets and pellet burners FOCUS has its advantages:

- savings on certified 50% fuel compared to gas heating costs;

- the possibility of using ash fuel of our own production;

- operation of the boiler with automatic fuel supply from the bunker.

With low costs and complete autonomy, a very high level of comfort is ensured at any time of the year. Another advantage of burners is their efficient operation in the off-season, when conventional solid fuel boilers provide large surpluses of heat. Accordingly, excess fuel consumption.

Choose a solid fuel boiler FOCUS

Order a boiler room project for production

What can the Plum EcoMAX boiler controller do?

Smart heating without a smart home