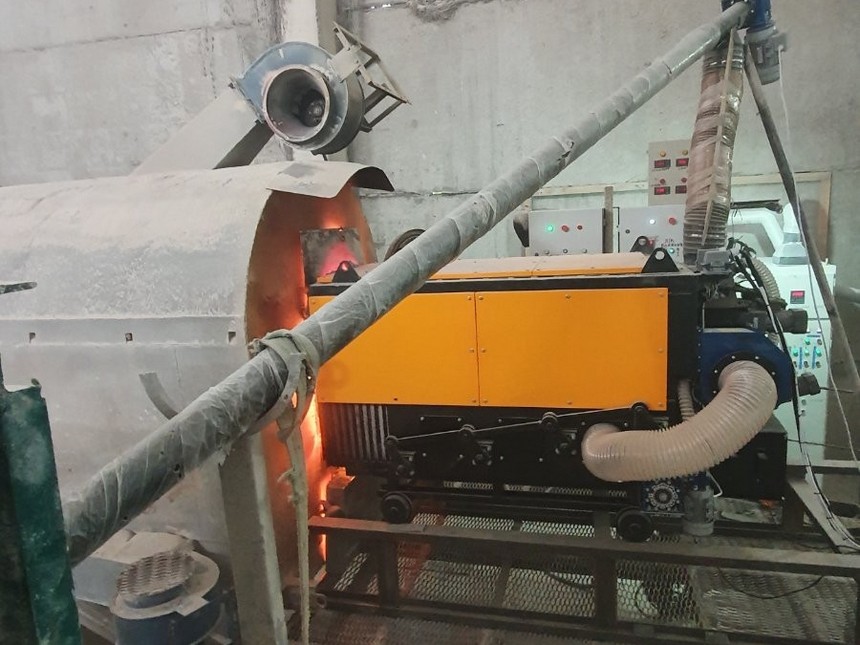

Pellet burners - equipment for optimization of drying complexes using volumetric combustion technology

At the moment, the industry is in demand for an integrated approach that can conceptually solve the problem of energy supply to the enterprise. In connection with expensive energy resources in the agro-industrial and food complex, new proposals are in demand. One of them is pellet burners, which are installed on any type of solid fuel boilers. Thanks to which on wood pellets it is possible to transfer drying complexes, bakery and smoking-cooking ovens, the high efficiency of which and low costs provide nothing more than bulk combustion.

Wood pellets and drying complexes

It should be noted that these types of production are characterized by high energy consumption. But it is precisely this technology, with the accompanying low price for wood pellets, that provides a high heat capacity. The benefits of using agropellets are obvious. Comparative characteristics of use on the example of a 45 kWh confectionery oven are shown in the table.

| Fuel | Calorific value according to standard | The required amount, 45 kW * h | Estimated fuel price | Fuel cost |

| Main gas | 8.6 kWh / m3 | 5.23 m3 | 8.07 UAH / m3 | UAH 42.2 |

| Liquefied gas | 12.8 kWh / l | 3.52 l | 11.60 UAH / l | UAH 40.83 |

| Wood pellets | 4.96 kWh / kg | 9.1 kg | 2,3 UAH / kg | UAH 20.93 |

| Diesel fuel | 11.1 kWh / l | 4.1 L | 15.80 UAH / l | UAH 64.78 |

| Electricity | — | 45 kWh | 1.68 kWh | UAH 75.6 |

For example, the ABM 0.65 drying complex runs on wood. For the issuance of 1000 kg of dried products, 0.5 m3 of dry firewood is required according to the standard. The savings when installing a pellet burner can reach 60%. This is realized due to volumetric combustion and increased efficiency, as well as the initial low price for wood pellets.

Moreover, when installing a module for pellet heating, production can be fully automated and does not require operational maintenance.

Volumetric combustion - technology features

Any combustion, regardless of the fuel, is a complex physicochemical process. It is based on an exothermic reaction, accompanied by an active release of heat. Moreover, the energy stored in the fuel is released in the form of heat radiation and light. Moreover, it is interesting that the glow zone is called a flame front or simply a flame. It is by him that we understand the concept of fire that appears as a result of combustion.

Burning at the core

The moment when mankind has mastered the technology of obtaining fire, has become defining for civilization. It was fire that opened before humanity the possibility of heat treatment, heating and, as a result, the development of production. Combustion is at the heart of many modern technologies and remains the main source of energy. Now 90% all energy on earth is obtained from various types of organic and inorganic fuels, with the help of which combustion is ensured.

The dependence on technology and the amount of resources used is very high. At the same time, it is wood pellet that belongs to renewable biofuel, and agropellet made from agricultural waste (flax, hemp, hay) is a cheap but very effective raw material for energy supply.

Volumetric combustion as a thermodynamic process

Before disclosing the features of the volumetric combustion technology, it is necessary to pay attention to the fact that combustion can proceed according to a different branched-chain mechanism with self-acceleration. In this case, the products formed as a result of combustion (gas) can perform mechanical work. In this case, a blast or shock wave occurs. Controlling these processes helps to significantly increase the efficiency and useful amount of heat energy released.

Bulk combustion is a product of thermodynamic reactions. It is realized in a flare burner, where a mixture of fuel and oxidizer (oxygen) is provided. As a result, ignition is observed in the entire volume of the combustible mixture with a higher return of thermal energy. To achieve volumetric combustion characteristics, the fuel must enter a homogeneous reactor at a certain temperature. This is exactly the kind of reactor that is, in fact, pellet burner.

The technology was obtained as a result of thermodynamic calculations that determine the equilibrium composition and amount of fuel, as well as its temperature during combustion. Calculation of the reaction kinetics makes it possible to achieve the parameters when the fuel burns in the burner in the entire volume, releasing more thermal energy.

Drying complexes: advantages of switching to wood pellets

In conclusion, it is worth mentioning the advantages of transferring production to wood and agricultural pellets:

- re-equipment does not require structural changes to the equipment;

- savings reach 60%;

- automation and remote control using Wi-Fi & GSM module is possible;

- burners are designed for different equipment capacities;

- pellets produce less carbon dioxide when burned;

- reduction of dependence on main utility networks;

- allows you to reduce the area for storing wood fuel required for the operation of drying complexes.

Wood pellet helps to significantly reduce the cost of any energy-consuming drying complex and increase the profitability of production. If you have any questions, please contact the specialists of the company that produces pellet burners FOCUS... Drying complexes can be equipped with remotely controlled automatic systems.