Classic boiler room for industries: heating system with hot water boilers and utilities

Despite the innovations in thermal power engineering, many boiler houses are deployed on the basis of classical thermal schemes. They are reliable, effective, imply operation in all non-standardized modes and have shown themselves well in practice. It is these heating schemes that undergo a simple upgrade. Most often, they are supplemented with automation systems. But the applied heating scheme for industrial boiler houses remains classic. It is about such a traditional project that we will now be talking about in our review. A classic boiler room for production can be implemented in this way or be based on a modern compact solution, as is done with boiler units FOCUS... We talk about him additionally.

A few words about thermal circuits

The first thing that is taught to heat and power engineering students is the ability to read thermal diagrams. We have already given the most used conventions, you can go to them by the link at the end of the article. But they can also be found in the corresponding Ukrainian standards, the use of which is recommended in the instructions for boilers FOCUS... Many specialists who do not have a fundamental education are not aware of the fact that in addition to the icons and symbols denoting nodes, there are also rules that simplify the reading of diagrams.

How to read thermal diagrams

In order for the projects to be read by all, without exception, specialists, there are their own requirements for the arrangement of elements in the drawing. In the upper part of the project there are hot water boilers, on the left - deaerators, at the bottom - pumps (recirculation and even lower network). Heat exchange circuits are placed under the deaerators, as well as tanks with water, makeup circuits with pumps, drainage and a blowdown well, if provided by the system. Accordingly, heating schemes for boiler rooms are not the same thing as heating schemes for private houses. At a minimum, they are divided by process.

Many beginners who read these lines about the components of a classic boiler room may feel insecure about the task at hand. Especially when it comes to the deployment of a production boiler house. But if you are on our site:

- firstly, you are interested in compact semi-industrial boilers;

- secondly, our specialists can also assist in the design of production and municipal boiler houses with a capacity of up to 2.2 MW on their basis.

In a modern boiler room, thanks to fittings and automation, the equipment is somewhat simpler than in the described classic case. However, how exactly a standard boiler house is deployed by production standards will be interesting even for non-specialists to know.

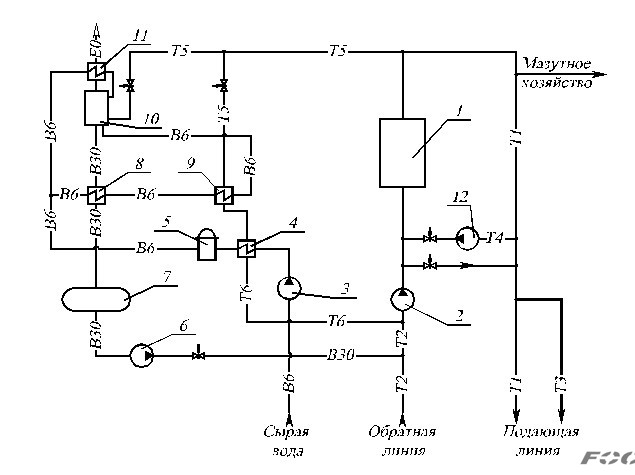

Boiler room diagram and its functionality

In the general case, the work of such a heating boiler house proceeds according to the following process. Water through the "return" (return heat circuit) enters the network pump 2 under a small pressure. Since we are talking about an industrial or communal heating system, characterized by a long heating network, it means leakage or natural evaporation of the coolant. Water is supplied to pump 2 from a make-up pump, which compensates for fluctuations in the volume of the coolant. Hot water is also supplied to pump 2, the heat of which has already been used in heat exchangers 9 and 4 for water treatment of purified and raw water.

A recirculation pump 12 has been introduced into the system. With its help, the corrosive effects in the system are reduced. The same pump supplies the heat carrier through the recirculation line to the heat consumers.

Modes of operation

The system is designed to operate in several modes, including the maximum winter one. In all modes, except for operation in severe frost, part of the water through the "return" after pump 2 is supplied to the bypass line, bypassing the boiler, and the supply line. It mixes with the hot stream and provides the standard thermal performance to the coolant.

To avoid a strong temperature difference in the system, raw water from pump 3 is fed to heat exchanger 4 for heating to a temperature of 18–20 ºC. Then it goes for filtration and purification. After that, the prepared coolant is heated by heat exchange circuits 8, 9 and 11, and then deaerated in a deaerator. From here (from the tank of deaerated water 7) with the help of a make-up pump 6, the coolant is supplied to the "return".

In most cases, the scheme of a production boiler house, including utilities, is simpler to carry out. However, simplification cannot be called an objective necessity, but is often simply a budget requirement of the customer. It is obvious that such a boiler house can operate in all unforeseen modes, providing consumers with safe heat and maintaining the trouble-free functionality of heating equipment in any operating situation.

Reliability and efficiency of boiler units and the boiler house as a whole

Any boiler house project involves the selection of equipment that meets a set of baseline conditions for conducting a feasibility study. Reliability and efficiency remain an important integrated characteristic. These parameters depend on the constancy of the flow rate of the heating medium and hot water for DHW. At the same time, there are specific requirements that are often ignored in domestic boiler rooms.

A classic industrial boiler room is a specialized heating station that must operate even in critical modes. For example, industrial boilers are more sensitive to corrosion. It occurs during low-temperature water supply and sulfuric acid contact with combustion products.

When burning fuels with a low sulfur content, water must be supplied to the convective heat exchanger with a temperature of at least 60 ºС. When using low-sulfur fuel, the heating agent is supplied with a temperature of at least 70 ºС, and with high-sulfur fuel - 110 ºС. To control the temperature of the water supply to the boiler, a recirculation pump is installed at the inlet.

Unlike domestic boiler rooms, industrial heating equipment is supplemented vacuum or atmospheric dearators... What functions this node carries will be considered additionally. In compact boiler rooms, it is quite rare.

DHW

Hot water treatment in heating circuits may differ in the type of placement of heat exchangers. In open systems, the coolant can also be used for hot water supply. In closed systems, DHW is provided using secondary heat exchange circuits.

Open systems are more demanding in terms of the volume of make-up water. It is required to provide more than 20%. This volume of water must be additionally purified and deaerated in order not to create potentially emergency situations in the operation of the boiler room. Since the flow rate is uneven during the day, storage tanks are used in communal systems to accumulate heated water. Of these, at the peak of consumption, water is supplied to consumers according to an enhanced schedule.

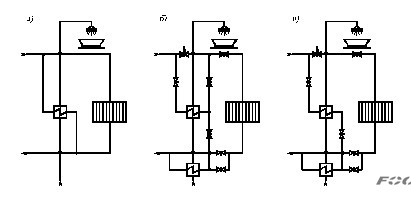

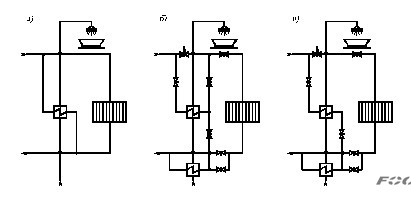

In open systems, special attention is paid to the quality of hot water, it should not be inferior to the quality of drinking water. If hot water preparation is carried out in local heat exchange circuits, then the connection is carried out according to the following schemes.

|

| Connection diagrams for local heat exchangers: a - parallel; b - two-stage sequential; v - mixed switching scheme |

Classic boiler room for production: calculation of the thermal diagram of a hot water boiler room

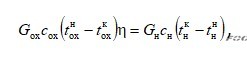

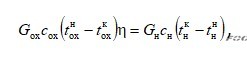

The thermal diagram of a hot water boiler house is calculated on the basis of two balances: heat and material, compiled for each node of the system. When there are no transitions of the coolant between two temperature regimes (hot and cold), the following equation is used:

|

where GOh, Gn - total consumption, respectively, of the cooled and heated heat carriers, kg / s; cOh, cn - average specific heat capacity of two types of heat transfer agents, kJ / (kg · ° C); ![]()

![]()

The calculation of the thermal scheme from the previously planned indicators should not give values that exceed the initial values by more than 3%. This is a margin of error. If the error is exceeded, the thermal circuit is checked for errors, and the calculation is repeated, but a classic boiler house for production must include the described modules.

Order a boiler room project for production