Functions and purpose of the two-, three- and four-way valve

Two-, three- and four-way valves have variable flow capacities depending on the position of the valve plug. This type of shut-off and control valves can perform shut-off, control, separation, distribution and mixing functions. Control is realized by means of a drive, which can be of hydraulic, electrical, pneumatic or electromagnetic nature. Discrete and analog type of control can be used to control two-, three- and four-way valves. The signal about a change in the position of the cone is given by the microcontroller, as a result, the valve takes a given position. Let's take a look, Why do you need a three-way valve in heating systems? And when it is replaced with a four-way.

With the help of three- and four-way valves, it is possible to solve complex problems of automating the heating process, pumping water into the heating system, and others. They are used, as a rule, in project systems, but having understood the installation and specifics, such valves will significantly improve the functionality of the heating systems of a private house.

Design features of two-, three- and four-way valve

Despite the initially identical principle of operation, due to the different design and functional features, the two-, three- and four-way valves have different purposes and applications.

Two way valve

The two-way valve works on the same principle as the ball valve. The inner cone changes the communication ability of the valve and, accordingly, the flow rate of the fluid passing through it. But this type of valves is used not only in heating, any thermodynamic medium can be the working medium.

Two-way valves have shown particularly high efficiency in heating and ventilation systems. They are used to change and control the parameters of thermal circuits, they are used as mixing, regulating, shut-off, distribution devices that change the conditions of the working environment.

Three-way valve

The three-way valve has a different design solution, although in fact it is two two-way valves in one. It is used to separate and mix streams with the desired degree of media penetration into each other. Thanks to three-way valves, raw water is mixed in heating and hot water systems. By analogy with a two-way valve, the working medium can be air, liquid or gaseous medium. The valve is controlled by a microcontroller and a servo drive. The regulation method is similar to the two-way valve.

Most often, three-way valves are used in heating systems as a control unit for controlled changes in heat transfer from heating devices, ventilation, and heat exchangers. The three-way valve has three branch pipes, two inlet and one outlet. The working medium is supplied to the inlet nozzles, where it is mixed depending on the presets and the position of the cone. Now it becomes clearer what a three-way valve is for.

In some cases, the three-way valves combine the functions of a back shut-off device to prevent backflow of liquid. By the nature of the capabilities, the valve assembly can have mixing, separating and switching functions. Three-way valves are widely used in automatic systems. An important characteristic and quality indicator is the tightness of the valve, provided by the internal seals.

Types of three-way valves

In practice, the following analog devices based on a 3-way valve are often used:

- mixing valve for hydraulically correct mixing of heat carrier with different temperature values. Protects heating circuits from overheating;

- The thermostatic valve maintains a constant temperature level in warm floors and radiators. It is often installed at the inlet to the boiler in order to guarantee stable temperature indicators of the coolant. It is used in various mixing and dividing units;

- underfloor heating valve, used to lower the temperature of the heating medium and keep it within the specified range of values. If the electronic version is used, then it becomes possible to regulate the parameters in each room. This applies only to the stable temperature of the coolant; heat transfer is not taken into account in this case.

Why a three-way valve is needed, you can figure it out on the example of a specific heating system, well understanding its functions and the principles of choosing this type of shut-off valves.

Four way valve

Consumers often have a question about the advisability of using a three- or four-way valve in the system. Most often they are used in the case of automation and support of special parameters in the heating and DHW circuit. Four-way valves are used, for example, to regulate the operation solid fuel boilers.

In some cases, a conventional valve is sufficient for these purposes.

Comparison of 3- and 4-way valve applications

For example, what is a three-way valve for and when a four-way valve is used:

- to obtain a stable temperature on the inlet and outlet lines of the boiler. The principle of operation of the three-way valve is to mix the coolant from the "return". The readings of the temperature sensors are transmitted to the controller, which controls the "overheating" of the heating circuit and regulates the state of the three-way valve, its position and throughput;

- three-way valves from some manufacturers support additional control signals and are, for example, two- and three-position. In the case of on-off regulation, the valve is either open (there is a mixture) or closed (there is no mixture). These valves have the disadvantage of not being able to intermediate position with a small admixture. These valves are not used in systems with stable flow and return temperatures. Since the mixing efficiency depends on a number of parameters (pipe diameter, flow rate, heat carrier resistance), a more accurate adjustment is required, provided by a three-position three-way or four-way valve.

- three-position three-way valves are used for gas boilers with a modulating burner or in similar cases, including in pellet solid fuel boilers (including cascade connection of boilers) when the automation smoothly reduces the combustion power and shuts down the boiler safely for the equipment, supporting the operation of the pump and other related equipment;

- three-way valves are used to maintain the temperature at the inlet to the solid fuel boiler. For example, the FR124 (Honeywell) regulator of a solid fuel boiler allows you to automate the process, but does not allow you to keep the temperature. For this, three-way valves are used. Note that temperature drops are also observed condensate precipitation, which threatens corrosion of the heat exchange circuit and increases the scale sediment. Cracks may appear in cast iron heat exchangers, as well as in the welded joints of the boiler generator.

We replace the three-way with a four-way

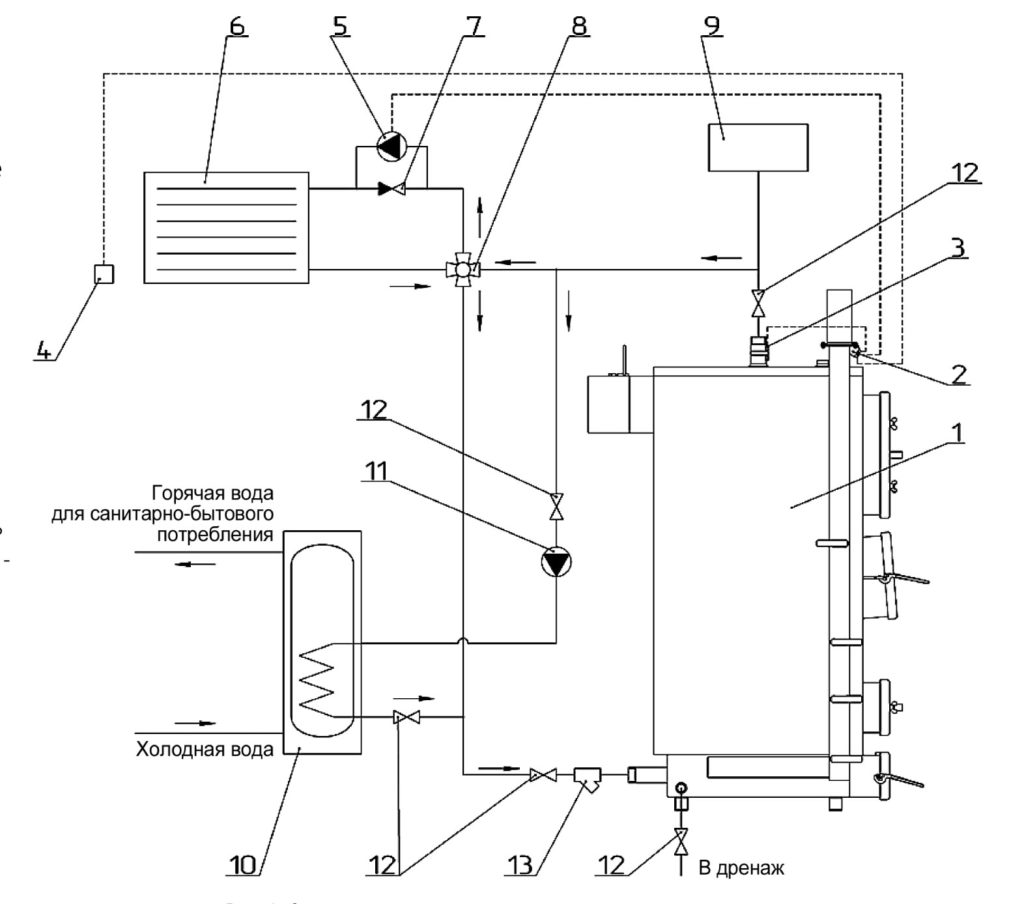

Instead of a three-way valve at the boiler inlet, in the latter case, a four-way valve can be used. Its tasks include not only modulating the parameters of the climate control, but also the internal physical characteristics of the boiler circuit and the associated heating system. The figure shows a typical thermal connection diagram. solid fuel boiler and a DHW tank, the boiler outlet is connected to a direct boiler line, where it is divided into DHW and heating. The separation is just carried out using a four-way valve, which ensures constant circulation in the boiler and heating circuit and regular supply of hot coolant to the DHW tank to maintain the temperature.

Typical thermal circuits

Rice. 1. Thermal diagram for connecting a solid fuel boiler to a heating system with forced circulation and a four-way valve.

Legend:

1 - boiler; 2 - boiler control automation unit; 3 - coolant temperature sensor; 4 - room thermostat; 5 - circulation pump; 6 - heat consumer; 7 - differential valve; 8 - four-way mixing valve; 9 - expansion tank; 10 - hot water boiler; 11 - boiler pump; 12 - shutoff valves; 13 - filter.

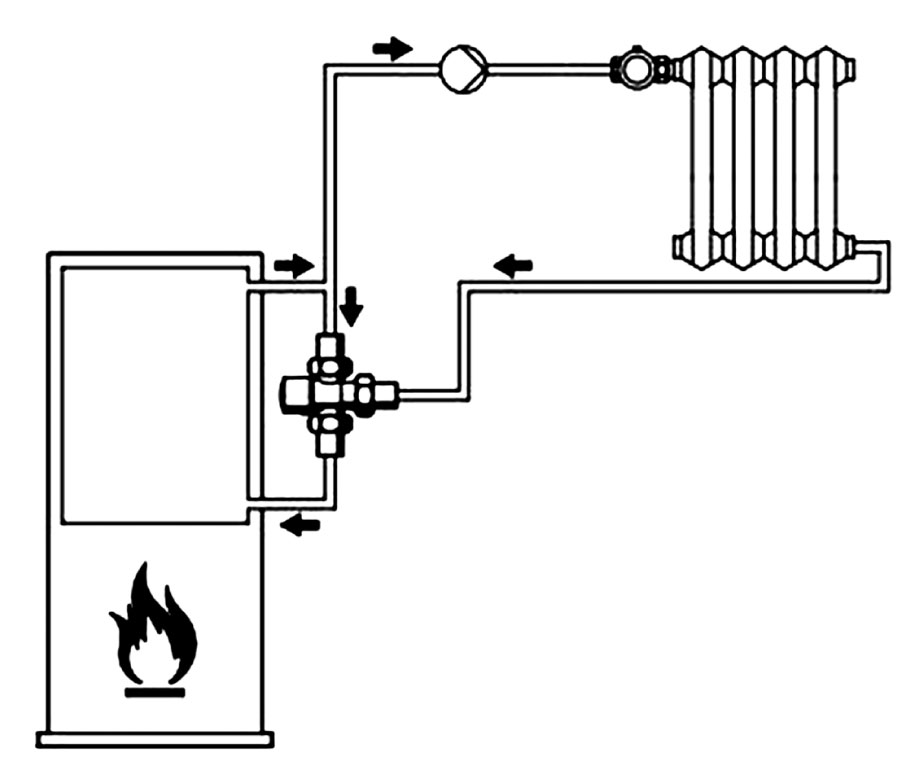

Rice. 2. Schematic diagram of the use of a thermostatic three-way valve for solid fuel boilers in order to equalize the temperature

Legend:

TC - solid fuel boiler; GK - gas boiler; 1 - four-way valve; 2 - temperature sensor; 3 - boiler pumps; 4 - heat consumer; 5 - circulation pump; 6 - controller.

Examples of what a three-way valve is needed for and a detailed diagram of the operation of a four-way valve is discussed in the article "Automation for the heating system".

Please note that to control the operation of the three-way valve you will need PLUM microcontroller for solid fuel boilers with manual loading.