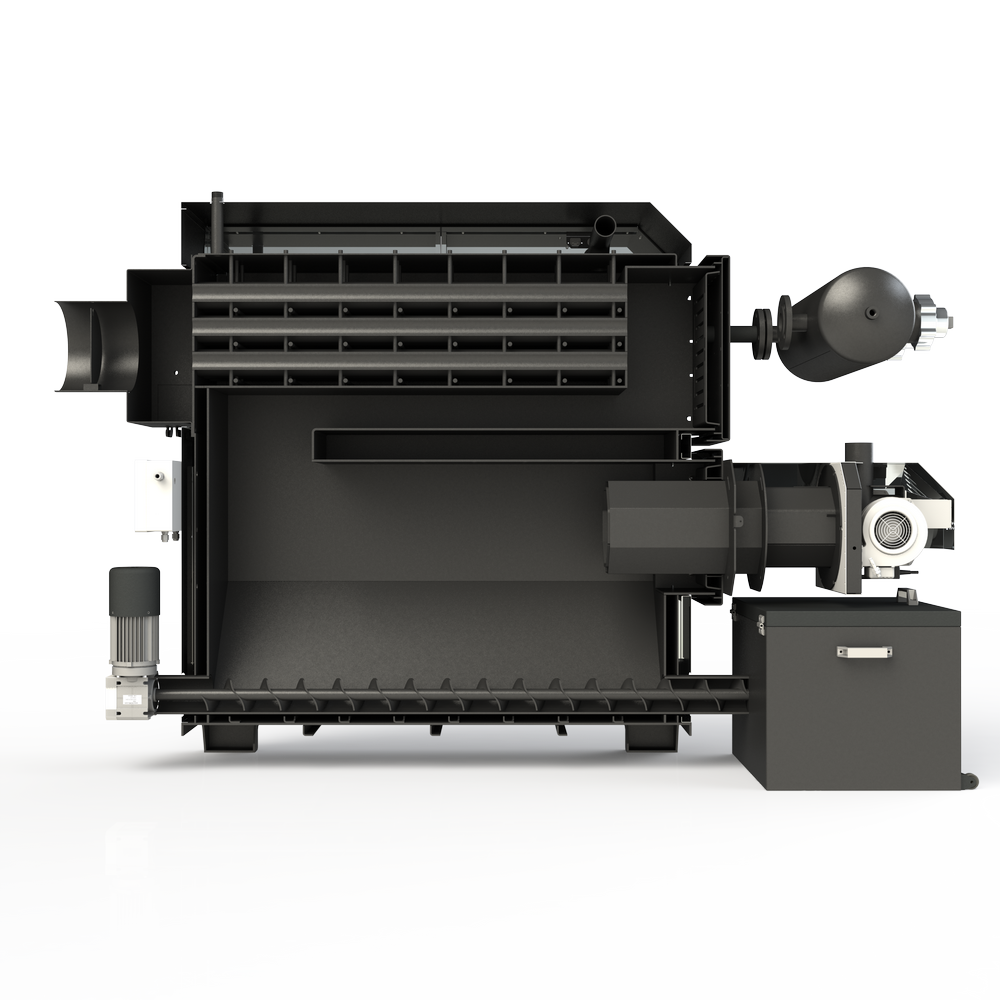

Автоматизированный пеллетный котел 40 кВт FOCUS (6-50 кВт) с функцией золоудаления, пневмоочисткой и промышленной пеллетной горелкой

Пеллетный котел 40 кВт FOCUS, с диапазоном программной регулировки мощности от 6 до 50 кВт, представляет собой высокоэффективную отопительную установку с полным набором автоматических функций. Этот котел разработан для работы на биотопливе, таком как агропеллеты, и специально адаптирован для использования топлива с повышенным содержанием золы (зольность до 10%), что делает его идеальным для автономного отопления жилых и коммерческих зданий.

Основные особенности:

- Диапазон мощности: от 6 до 50 кВт, с возможностью тонкой настройки под различные условия эксплуатации.

- Топливные материалы: как древесные пеллеты, так и агропеллеты с зольностью до 10%, такие как пеллеты из подсолнечника, кукурузы, гречки и других культур.

- Полная автоматизация: пеллетный котел 40 кВт FOCUS может автоматически включаться, выключаться, очищаться от золы с помощью механических средств автоматического шнекового золоудаления и пневмоустановки и поддерживать необходимую температуру в системе.

Автоматизированные системы управления:

- Шнековое золоудаление: встроенный шнековый механизм для автоматического удаления золы в специальный контейнер, что уменьшает необходимость частого обслуживания.

- Пневматическая очистка теплообменника: система, использующая ресивер и электромагнитные клапаны, обеспечивает регулярную очистку теплообменника от загрязнений и пепла, что повышает его эффективность.

- Поддержка насосных систем: пеллетный котел 40 кВт FOCUS с помощью микроконтроллера способен управлять насосами для горячего водоснабжения и отопления, интегрируясь в сложные отопительные комплексы.

- PID-регулятор: обеспечивает точную настройку работы горелки и котла, повышая эффективность и совместимость с системами умного дома.

- Удаленное управление: котел поддерживает работу с комнатными термостатами и интернет-модулем, что позволяет контролировать его работу через мобильные приложения и другие устройства.

Преимущества конструкции:

Пеллетная горелка:

- Керамические свечи розжига: обеспечивают надежное автоматическое зажигание при любых условиях.

- Подвижный моноколосник: механизм, который перемешивает топливо и удаляет золу, обеспечивая стабильную работу горелки и минимизируя ручное обслуживание.

- Шнековый питатель топлива: отвечает за надежную и стабильную подачу пеллет в камеру сгорания.

- Инфракрасный датчик пламени: контролирует наличие огня для повышения безопасности и эффективного управления процессом сжигания.

- Подача воздуха в две зоны: первичный и вторичный воздух подаются раздельно, что оптимизирует процесс горения и снижает выбросы.

Конструкция котла:

- Горизонтальный жаротрубный теплообменник: обеспечивает эффективное снятие тепла факела пеллетной горелки с минимальными теплопотерями (КПД — 96%).

- Увеличенный зольник: дает возможность реже чистить котел, что особенно полезно при использовании топлива с высоким содержанием золы.

- Гибридный теплообменник (плюс пластинчатый, работающий как золоуловитель): снижает износ оборудования и увеличивает общую эффективность теплообмена.

- Надежная теплоизоляция: базальтовая минеральная вата толщиной 50 мм предотвращает теплопотери и поддерживает стабильную работу системы.

- Стильный корпус из полированной стали: стальной корпус толщиной 6 мм для теплообменника и 4 мм для водяной рубашки обеспечивает долговечность и прочность котла.

Дополнительные функции:

- Поддержка микроконтроллером трехходовых и четырехходовых клапанов, а также насосов IMP Pumps, что позволяет улучшить защиту от холодной обратки и повысить КПД системы на 30%.

- Легкость установки: использование соединений типа Victaulic значительно упрощает и ускоряет процесс безсварного монтажа.

- Каскадное подключение: возможно подключение нескольких котлов в каскад для увеличения общей мощности системы до 2,5 МВт.

Материалы и конструкции:

- Корпус: изготовлен из стали 09Г2С, с толщиной теплообменника 6 мм и водяной рубашки 4 мм для долговечности.

- Теплоизоляция: выполнена из базальтовой минеральной ваты толщиной 50 мм для минимизации потерь тепла.

- Внешний кожух: из нержавеющей стали AISI201, устойчива к высоким температурам и коррозии.

Экономичность и надежность:

Пеллетный котел 40 кВт FOCUS предоставляет возможности и экономически эффективен, благодаря сниженным затратам на обслуживание. Это делает его оптимальным выбором для автономного отопления частных домов и коммерческих объектов с различными потребностями в тепле.

Функции

Пеллетный котел 40 кВт FOCUS (6-50 кВт) имеет такие функции, как:

- регулировка мощности в пределах 6 кВт – 50 кВт;

- 5 базовых уровней безопасности;

- автоматическая работа: розжиг, тушение, авто-очистка в режиме работы, очистка от основной золы при гашении;

- автоматическое шнековое золоудаление во внешний контейнер золоприёмник;

- автоматическая пневматическая очистка теплообменника котла;

- автоматическая очистка горелки в общую систему золоудаления котла;

- керамическая свеча розжига, дублирование свечей розжига;

- низкое энергопотребление (800 Вт);

- PID-регулирование (возможность точного регулирования горелкой с помощью аналогового управляющего сигнала, в том числе, в рамках технологии «умный дом»);

- подвижный, съёмный моно-колосник из хромистого сплава для механической очистки горелки;

- управление насосами (горячая водоподготовка и отопление);

- работа с комнатным термостатом и интернет-модулем;

- работа с погодным регулированием;

- встроенный зольный фильтр.

Соответствие стандартам:

Оборудование сертифицировано по ГОСТ 32452-2013 (EN 15270:2007), что подтверждает его соответствие высоким стандартам качества и безопасности. На котел предоставляется гарантия сроком 12 месяцев.

Комплект поставки:

- Пеллетный котел 40 кВт FOCUS в сборе с горелкой, система шнекового золоудаления, система пневматического золоудаления;

- откатной контейнер сбора золы — комплект;

- интернет-модуль EcoNet;

- датчик погоды;

- датчик температуры дымовых газов;

- датчик температуры обратки котла;

- подающий шнековый транспортер – 2 м;

- гофрированная труба ПВХ – 1 м;

- контроллер по управлению пеллетной горелкой;

- документация.

Этот пеллетный котел 40 кВт FOCUS обеспечивает высокую степень комфорта, надежность и экономичность при минимальных затратах на эксплуатацию, что делает его выгодным решением для долгосрочного использования.

Оборудование для пеллетных котельных

Устройства и модули, повышающие уровень автономности системы отопления и функционально дополняющие пеллетный котел 40 кВт FOCUS:

- комплекты обвязки с трехходовым или четырехходовым клапаном интегрированные в систему управления котла;

- бункеры для хранения и подачи пеллеты;

- комнатный сенсорный регулятор EcoSter;

- дополнительные датчики температуры.

Проконсультируйтесь по особенностям развертывания отопительных контуров и подключения у наших специалистов.

Габариты

Указаны в каждой позиции отдельно.

Диаметр дымохода

180 мм

Требования к помещению котельной

При проектировании котельной, где будет установлен пеллетный котел 40 кВт FOCUS, необходимо придерживаться требований:

- МДНАОП 0.001.26-96;

- ДБН В.2.5-ХХ: 20ХХ;

- СНиП 2.04.05-91 «Отопление, вентиляция и кондиционирование»;

- СНиП II-35-76 «Котельные установки».

Интересно почитать

Процесс эксплуатации пеллетной горелки в деталях

Какой твердотопливный котел купить для производства

Отзывы

Отзывов пока нет.