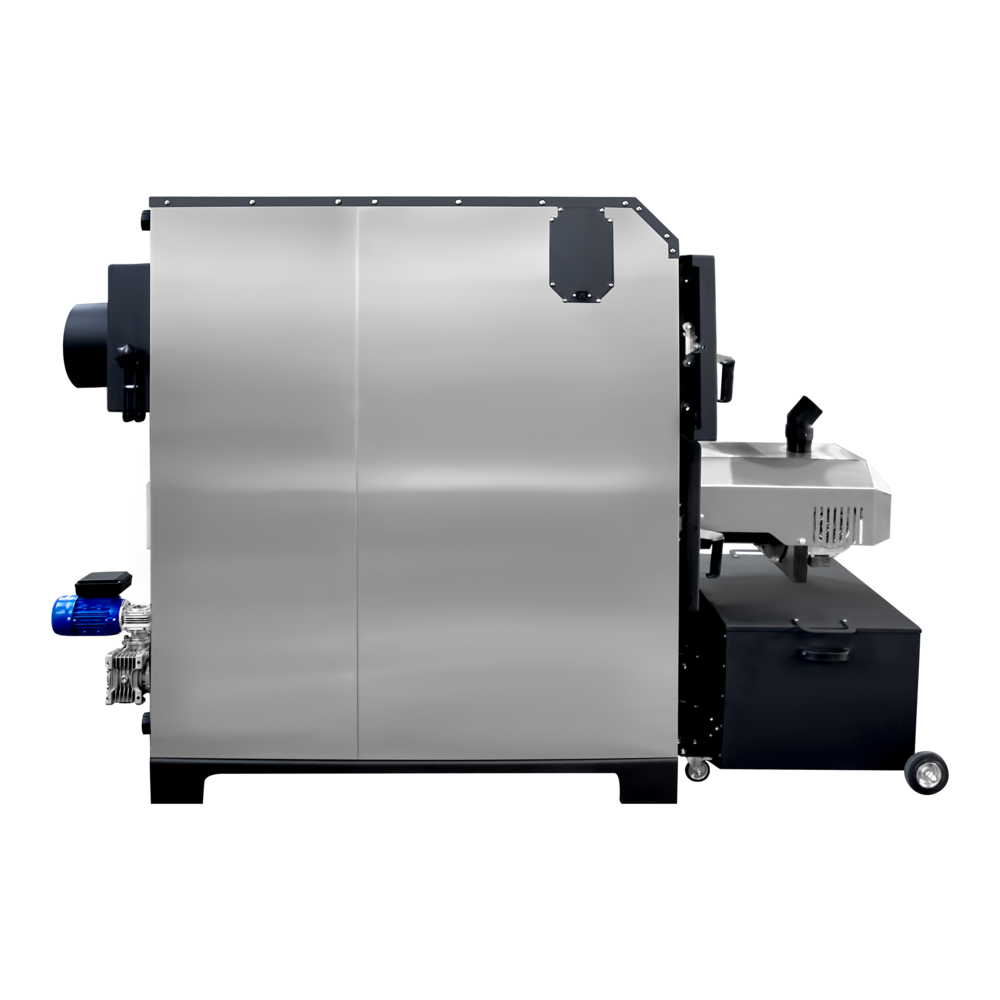

Автоматизированный пеллетный котел 30 кВт FOCUS для домохозяйств с встроенной системой золоудаления

Автоматизированный пеллетный котел 30 кВт FOCUS особенно привлекателен для домохозяйств благодаря его системе золоудаления, которая значительно снижает трудозатраты на обслуживание. В домах, где важны автономность и простота в эксплуатации, автоматизация этого процесса имеет огромное значение. Золоудаление значительно упрощает работу котла, работающего на высокозольном топливе, то есть на грануле, изготовленной из агроотходов.

Система золоудаления и её значение для домохозяйства:

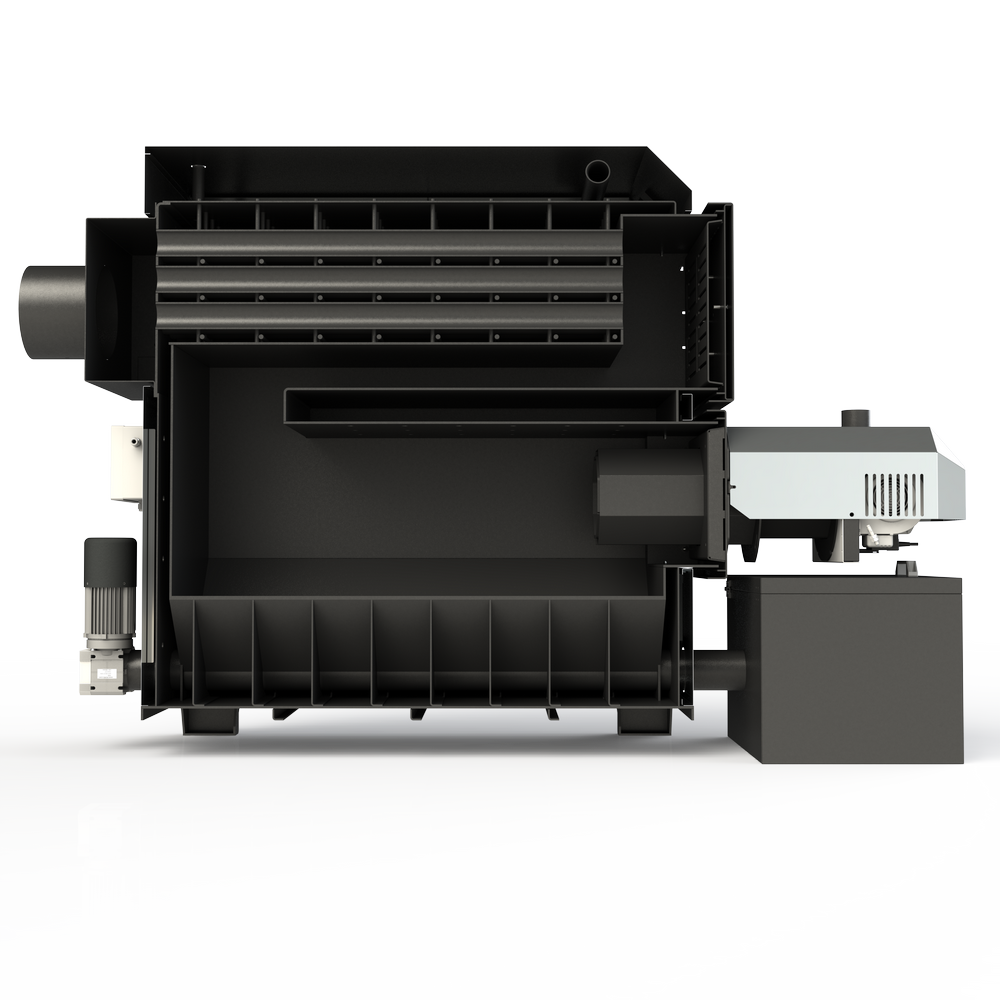

- Встроенная система шнекового золоудаления

Ключевая особенность этого котла — автоматическое шнековое золоудаление. В обычных котлах с ручным обслуживанием пользователю приходится регулярно очищать зольник от накопившейся золы, что требует времени и усилий. В случае с FOCUS 30, весь процесс золоудаления автоматизирован: шнек перемещает золу из топки в специальный зольный контейнер, который можно опорожнять значительно реже. Это особенно актуально для домохозяйств, так как:- Экономия времени — нет необходимости постоянно контролировать уровень золы и чистить котел вручную.

- Уменьшение ручного труда — все работы по удалению золы сведены к минимуму, что особенно удобно для людей с ограниченными физическими возможностями или при отсутствии желания заниматься этим трудоемким процессом.

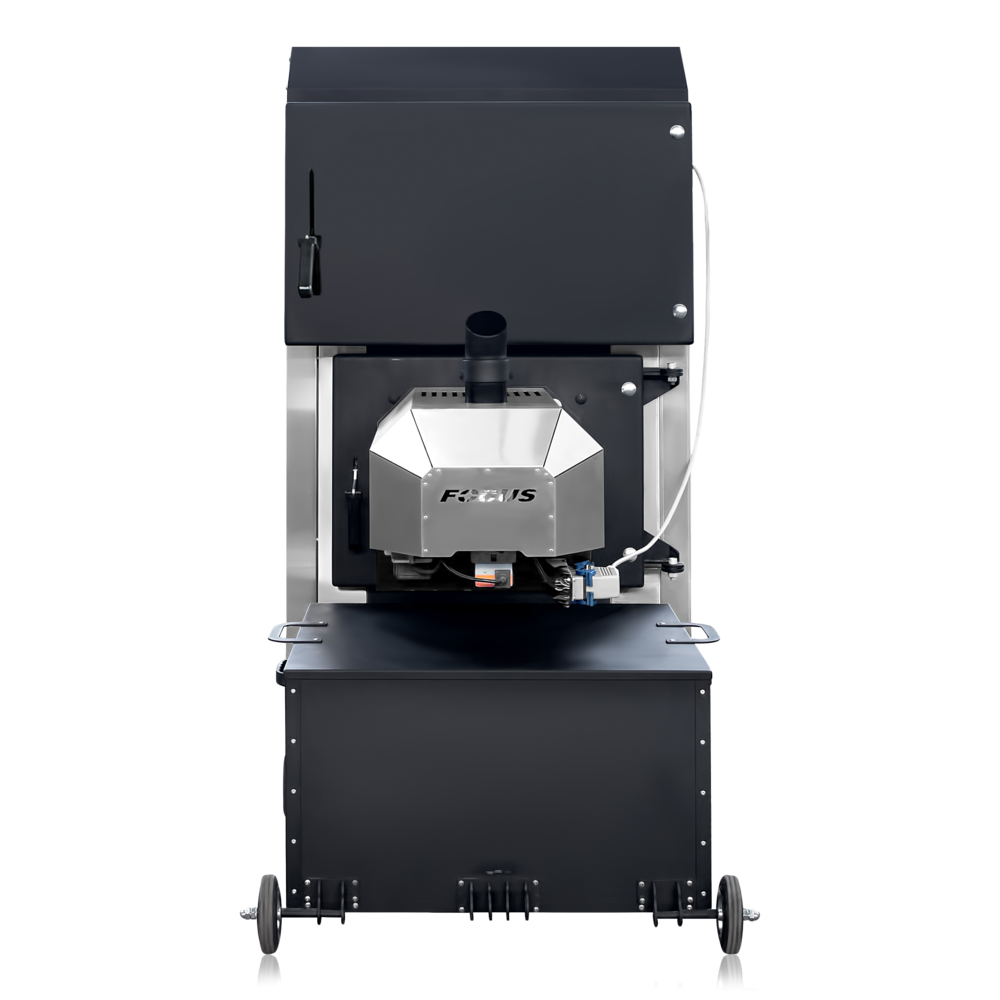

- Откатной контейнер для золы

Пеллетный котел 30 кВт FOCUS оснащен съемным контейнером для сбора золы, который можно легко выкатить и очистить. Этот контейнер имеет большую емкость, что позволяет проводить очистку всего несколько раз в сезон даже при использовании высокозольных агропеллет. Для домохозяйств это означает:- Продление интервалов между обслуживаниями — зольник рассчитан на работу с высокозольным топливом, что позволяет котлу эффективно работать продолжительное время без необходимости частой чистки.

- Удобство при удалении золы — пользователю достаточно просто вытащить контейнер и опорожнить его, что намного проще по сравнению с традиционными методами чистки зольника.

- Очистка пеллетной горелки в систему золоудаления

Встроенная система золоудаления также распространяется на горелку, что означает, что зола и налет, которые могут образовываться в процессе сгорания топлива, автоматически направляются в общий зольник котла. Это важный момент, поскольку горелка остается чистой и эффективной даже при работе с низкокачественными, высокозольными пеллетами.Для домохозяйств это:- Повышение эффективности работы — автоматическая очистка горелки предотвращает накопление золы, что способствует стабильной работе котла и снижению вероятности поломок.

- Снижение затрат на обслуживание — отсутствие необходимости часто вызывать специалистов для очистки и настройки горелки снижает эксплуатационные расходы.

Преимущества автоматизации золоудаления для домохозяйств:

- Работа с высокозольными пеллетами

Пеллетный котел 30 кВт FOCUS разработан с учетом использования агропеллет, которые дешевле, но производят больше золы. Домохозяйства могут сэкономить на топливе, используя такие пеллеты, не беспокоясь о частых очистках. Система золоудаления решает проблему накопления золы даже при использовании топлив с зольностью до 10%, что дает владельцам возможность выбрать более экономичное топливо без ущерба для удобства и эффективности работы котла. - Долгие периоды автономной работы

Автоматическая система золоудаления позволяет котлу работать в автономном режиме значительно дольше по сравнению с аналогами без подобной функции. Это идеальный выбор для домохозяйств, которые хотят минимизировать вмешательство в работу отопительной системы, особенно в зимний период, когда котел работает круглосуточно. Пользователям не нужно каждый день контролировать состояние котла, что освобождает их время для других дел. - Чистота и удобство

Встроенная система автоматической очистки уменьшает количество пыли и грязи, которые обычно сопровождают процессы ручного золоудаления. Домохозяйства могут поддерживать чистоту в котельной и избегать неприятных ситуаций, связанных с разбрасыванием золы.

Для домохозяйств, где важна автономная, эффективная и удобная в обслуживании отопительная система, пеллетный котел 30 кВт FOCUS с автоматической системой шнекового золоудаления является отличным решением. Он минимизирует потребность в частом обслуживании, экономит время и силы пользователей, при этом поддерживая высокую производительность и долгие периоды автономной работы даже на дешевом высокозольном топливе.

Функции и комплектация

Функционал пеллетного котла 30 кВт FOCUS (6-35 кВт):

- мощность динамично регулируется в диапазоне 6 кВт – 35 кВт;

- 5 базовых безопасности;

- автоматическая работа: включение, тушение, золоудаление, очистка от основной золы при гашении;

- золоудаление с помощью в отдельно стоящий золоприёмник;

- автоматическая очистка факельной горелки в общую систему золоудаления котла;

- керамическая свеча розжига, дубликат свечей розжига;

- низкое потребление электричества (800 Вт);

- PID-управление (в том числе, для технологии «умный дом» с помощью аналогового сигнала);

- подвижный (съёмный) моно-колосник, изготовленный из сплава хрома, для очистки горелки;

- управление насосами (ГВС, отопление, трех- и четырехходовыми клапанами);

- работа с цифровыми устройствами регулирования контурами отопления и интернет-модулем;

- погодный регулятор, включение при снижении температуры воздуха;

- встроенный в теплообменный контур зольный фильтр на основе теплообменника пластинчатого типа.

Пеллетный котел 20 кВт FOCUS разработан в соответствии с ГОСТ32452-2013 (EN 15270:2007). Гарантия 12 месяцев.

Комплект поставки:

- пеллетный котел 30 кВт FOCUS в сборе с факельной горелкой, система шнекового золоудаления;

- откатной контейнер сбора золы — комплект;

- интернет-модуль EcoNet;

- датчик погоды;

- датчик температуры дым газов;

- датчик температуры обратки котла;

- подающий шнековый транспортер – 2 м;

- гофрированная труба ПВХ – 1 м;

- контроллер по управлению пеллетной горелкой;

- документация.

Оборудование для пеллетных котельных

Устройства и модули, повышающие уровень автономности системы отопления:

- комплекты обвязки с трехходовым или четырехходовым клапаном для котельной, где используется пеллетный котел 30 кВт FOCUS, программно-интегрированные в систему управления котла;

- бункеры для хранения и подачи пеллеты;

- комнатный сенсорный регулятор EcoSter;

- дополнительные датчики температуры.

Проконсультируйтесь по особенностям развертывания отопительных контуров и подключения у наших специалистов. Используйте пеллетный котел 30 кВт FOCUS для автоматизации контуров обогрева.

Габариты

Указаны в каждой позиции отдельно.

Диаметр дымохода

180 мм

Требования к помещению котельной

При проектировании необходимо придерживаться требований:

- МДНАОП 0.001.26-96;

- ДБН В.2.5-ХХ: 20ХХ;

- СНиП 2.04.05-91 «Отопление, вентиляция и кондиционирование»;

- СНиП II-35-76 «Котельные установки».

Интересно почитать

Процесс эксплуатации пеллетной горелки в деталях

Какой твердотопливный котел купить для производства

Отзывы

Отзывов пока нет.