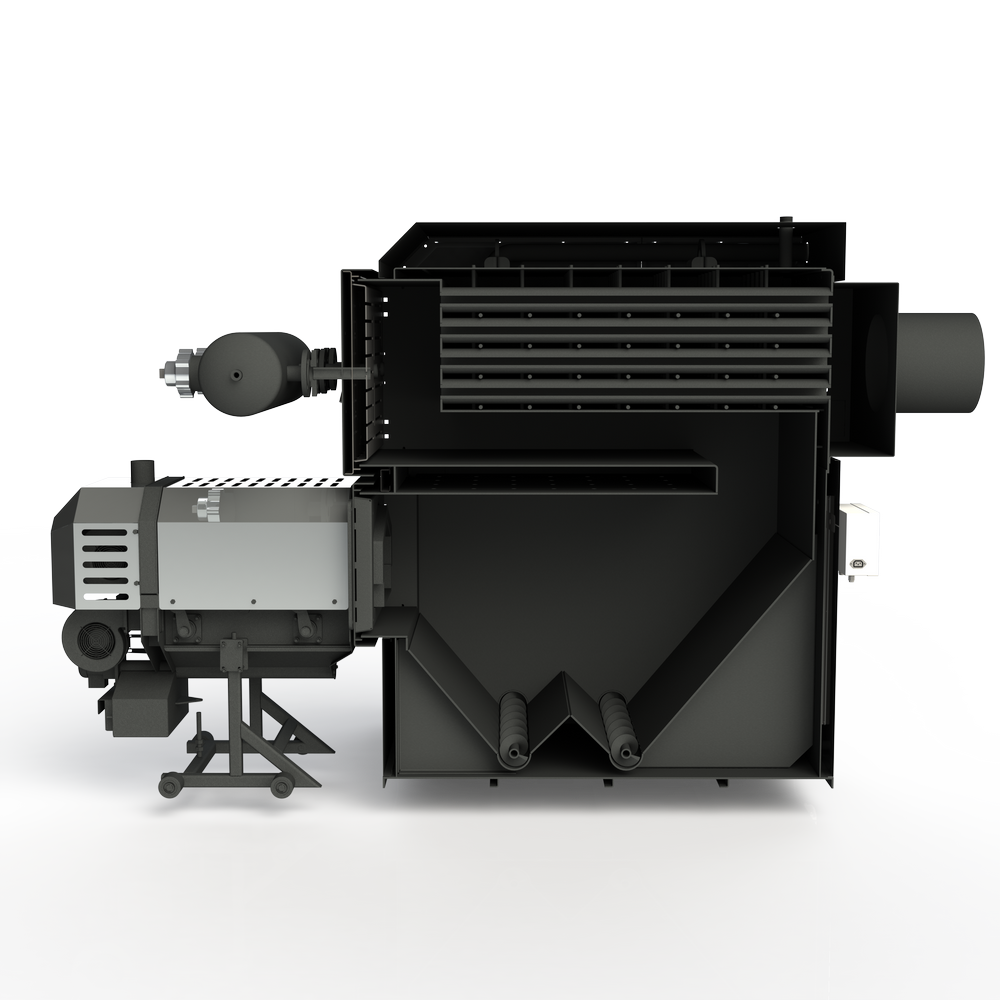

Автоматизированный пеллетный котел 200 кВт FOCUS с встроенной промышленной пеллетной горелкой, встроенная система шнекового золоудаления с откатными контейнерами сбора золы, встроенная система пневматической очистки теплообменника с ресивером. Автоматика поддерживает управление циклами пневмоочистки теплообменника.

Автоматизированный пеллетный котел FOCUS, рассчитанный на бескомпромиссную работу в форм-факторе единого блока. Основной акцент при инженерной разработке и производстве котла сделан на эффективность теплосъёма именно при работе твердотопливного котла с факельной пеллетной горелкой на высокозольной (агро) пеллете. Это основа экономической целесообразности покупки и последующей окупаемости оборудования полупромышленного класса, которое может успешно использоваться на предприятиях любого типа и в домохозяйствах для комплектации автономных и автоматических котельных типа OFFGride требуемой мощности и с климат-контролем.

Также подразумевается и уменьшение объема ручного труда по очистке котла и теплообменника от золы и налёта, увеличение периодов между очистками, удаление золы в откатные контейнеры.

Основные преимущества :

- Максимальный зольник для работы на высокозольном топливе;

- Встроенная система шнекового золоудаления из зольника котла;

- Встроенные откатные контейнеры для сбора и выноса золы;

- Встроенная система шнекового золоудаления из подколосникового пространства горелки в зольник котла;

- Встроенная система пневматической очистки теплообменника (ресивер и электро клапана);

- Очистка пеллетной горелки осуществляется в зольник котла, и через систему шнекового золоудаления во внешние контейнеры;

- Встроенная автоматика управления циклами пневмоочистки теплообменника;

- Низковольтное питание электроклапанов пневмоочистки (24 вольта постоянного тока).

Гибридная структура теплообменной части котла

(учитывающая инфракрасное излучение факела горелки)

Участок снятия первичного теплового напряжения факела (при этом конструкционно исключен участок точечного воздействия факела на конструктив теплообменника) выполняет параллельно задачу осаждения тяжелых частиц летучей составляющей излучения факела на практике работает как зольный фильтр:

- Максимально развита конвективная часть теплообменника в комплексе с высокоэффективным горизонтальным теплообменником;

- Продуманное удобное обслуживание теплообменника (широкий люк, горизонтальная очистка, зольная камера перед дымоходом);

- Зольник котла высокой емкости рассчитан для работы в промышленных условиях. При правильном подборе оборудования, даже на высокозольной пеллете;

- Расположение двери котла на пеллетном предтопке в откатном варианте;

- Котел дополнительно ( по желанию заказчика) комплектуется готовой обвязкой из трехходовым или четерехходовым клапаном с насосами IMP Pumps. Что в комплексе с управляющей автоматикой дает защиту от холодной обратки из системы отопления и отсутствие конденсации в котле. Это в свою очередь на 30% увеличивает КПД в сравнении с аналогичным котлом без защиты обратки и на холодной системе (когда обратка ниже 40*С). Отсутствует необходимость подбора смесительного оборудования и согласование с автоматикой котла;

- Для удобства и быстроты монтажа – котел оборудован системой быстрых соединений Victaulic (Виктолические соединения, они же Грувлок). Для оперативной работы, гарантированно качественного соединения (не требует симметричной затяжки как фланцевое соединение, не требуется проведение сварочных работ на месте монтажа), допускает небольшие перекосы при монтаже ( до 2-3*) что дает свободу монтажнику в случае отклонений помещения от проектных размеров. В комплекте с котлом идут муфты и отводы под приварку или резьбовое соединение (указывается при заказе).

Монтаж и конструкция котла

Котел и система соединений расчитаны для сборки котельной по типу каскада, когда изначально не требуется вся мощность (например при строительстве крупного обьекта), так и при возникновении потребности в увеличении проектной мощности – безболезненно добавляется несколько котлов суммарной мощностью до 2.2-2.5МВт. При этом наличие трехходовых клапанов на каждом котле и гидрострелки в системе отопления – отключает неработающий котел от протока, не ограничивая проток системы и не охлаждая теплоноситель через теплообменник неработающего котла.

- Материал котла – конструкционная сталь 09Г2С. Толщина стенок теплообменной части (топка и первичный теплообменник, лудки) – 6мм. Толщина внешней оболочки водяной рубашки котла – 4мм.

- Теплоизоляция – базальтовая минеральная вата толщиной 50мм.

- Кожух котла – нержавеющая шлифованная сталь AISI201.

- Регулируемые петли и замки для точной настройки плотного прилегания двери зольника и теплообменника к проему.

- Возможность изменения стороны открытия дверей.

- Предварительно установленная на дверь теплообменника система пневматической очистки;

- Съёмные откатные контейнеры системы шнекового золоудаления котла.

- Автоматическая очистка горелки в общую систему золоудаления котла;

- Гибридный теплообменник из пластинчатого и жаротрубного. Где пластинчатый ход снимает напряжение факела и осаждает основную массу тяжелых частиц что особенно актуально на работе с высокозольной или агро пеллетой.

- Максимально развитая конвективная жаротрубная часть теплообменника реально соответствующая теплообмену.

- Большая дверь для удобного доступа и полной очистки поверхностей теплообменника.

Пеллетная горелка факельного типа

Пеллетная горелка ТМ «FOCUS», которая входит вданный комплект котла будет работать как на чистой древесной пеллете, так и на агропеллете с зольностью до 10% (пеллета из семечки, кукурузы, гречки, риса, мебельная, солома).

Преимущества горелки:

- Автоматический розжиг (установлены 2 керамические свечи FKK для бесконтактного воздушного розжига пеллет);

- Шнек подачи топлива в камеру сгорания горелки;

- Встроенный датчик температуры шнека горелки (безопасность, автоматика выключит подачу топлива с выдачей сигнала аварии).

- Встроенный датчик пламени инфракрасного диапазона, для фиксации и контроля уровня излучения пламени (безопасность, автоматика фиксирует наличие и отсутствие пламени, используя соответствующие алгоритмы поведения);

- Подобранные пропорции первичного и вторичного воздуха, для правильной организации сжигания топлива;

- Высоконадежный кривошипный привод – двигает колосниковую решетку;

- Наборная колосниковая решетка для авто-очистки горелки. Наборные элементы с жаропрочной марки хромистого чугуна ЧХ32;

- Камера сгорания горелки футерована огнеупорным кирпичом, выполняет функции катализатора для дожига балластных газов , повышает КПД выработки тепла горелкой (повышая температуру пламени);

- Все модели факельных горелок имеют «разрыв» линии подачи топлива, обеспечивая безопасность эксплуатации оборудования;

- Контроллер, позволяющий легко настраивать оборудование;

- Модуль интернет соединения как дополнительная опция — удобен для удаленной настройки и управления горелкой, создание статистики потребления топлива, ошибок, графика мощности, температур и т.п.

Функции и комплектация

Функционал пеллетного котла 200 кВт FOCUS (80-220 кВт):

- регулировка мощности в пределах 80 кВт – 220 кВт;

- 5 базовых уровней безопасности;

- автоматическая работа: розжиг, тушение, авто-очистка в режиме работы, очистка от основной золы при гашении;

- автоматическое шнековое золоудаление во внешние контейнеры золоприёмники;

- автоматическая пневматическая очистка теплообменника котла;

- автоматическая очистка горелки в общую систему золоудаления котла;

- керамическая свеча розжига, дублирование свечей розжига;

- низкое энергопотребление (800 Вт);

- PID-регулирование (возможность точного регулирования горелкой с помощью аналогового управляющего сигнала, в том числе, в рамках технологии «умный дом»);

- подвижная наборная чугунная колосниковая решётка для механической очистки горелки;

- управление насосами (горячая водоподготовка и отопление);

- работа с комнатным термостатом и интернет-модулем;

- работа с погодным регулированием;

- встроенный зольный фильтр.

Пеллетный котел соответствует ГОСТ32452-2013 (EN 15270:2007). Предоставляется гарантия 18 месяцев.

Комплект поставки:

- Пеллетный котёл 200кВт в сборе с горелкой, система шнекового золоудаления, система пневматического золоудаления;

- откатные контейнеры сбора золы — комплект;

- интернет-модуль EcoNet;

- датчик погоды;

- датчик температуры дым газов;

- датчик температуры обратки котла;

- подающий шнековый транспортер – 2 м;

- гофрированная труба ПВХ – 1 м;

- контроллер по управлению пеллетной горелкой;

- документация.

Оборудование для пеллетных котельных

Устройства и модули, повышающие уровень автономности системы отопления:

- комплекты обвязки с трехходовым или четырехходовым клапаном интегрированные в систему управления котла;

- бункеры для хранения и подачи пеллеты;

- комнатный сенсорный регулятор EcoSter;

- дополнительные датчики температуры.

Проконсультируйтесь по особенностям развертывания отопительных контуров и подключения у наших специалистов.

Габариты

Указаны в каждой позиции отдельно.

Диаметр дымохода

320 мм

Требования к помещению котельной

При проектировании необходимо придерживаться требований:

- МДНАОП 0.001.26-96;

- ДБН В.2.5-ХХ: 20ХХ;

- СНиП 2.04.05-91 «Отопление, вентиляция и кондиционирование»;

- СНиП II-35-76 «Котельные установки».

Интересно почитать

Процесс эксплуатации пеллетной горелки в деталях

Какой твердотопливный котел купить для производства

Отзывы

Отзывов пока нет.