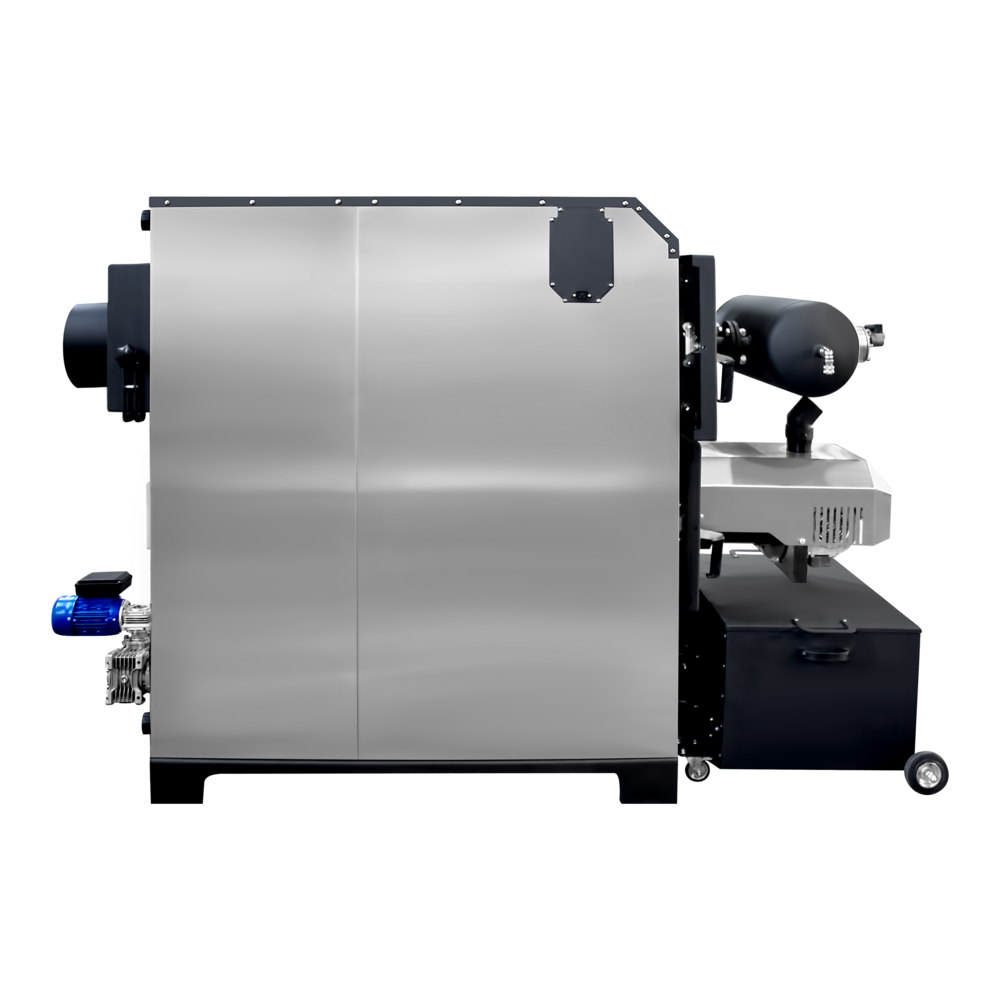

Автоматизированный пеллетный котел FOCUS 120 кВт с золоудалением и пневмоочисткой

Пелетный котел FOCUS 120 кВт оснащен промышленной пеллетной горелкой и системой шнекового золоудаления. Основное назначение — высокоэффективная работа с агропеллетами, где важен непрерывный теплосъём с минимальным обслуживанием.

Пелетный котел FOCUS 120 кВт: конструкция и основные элементы

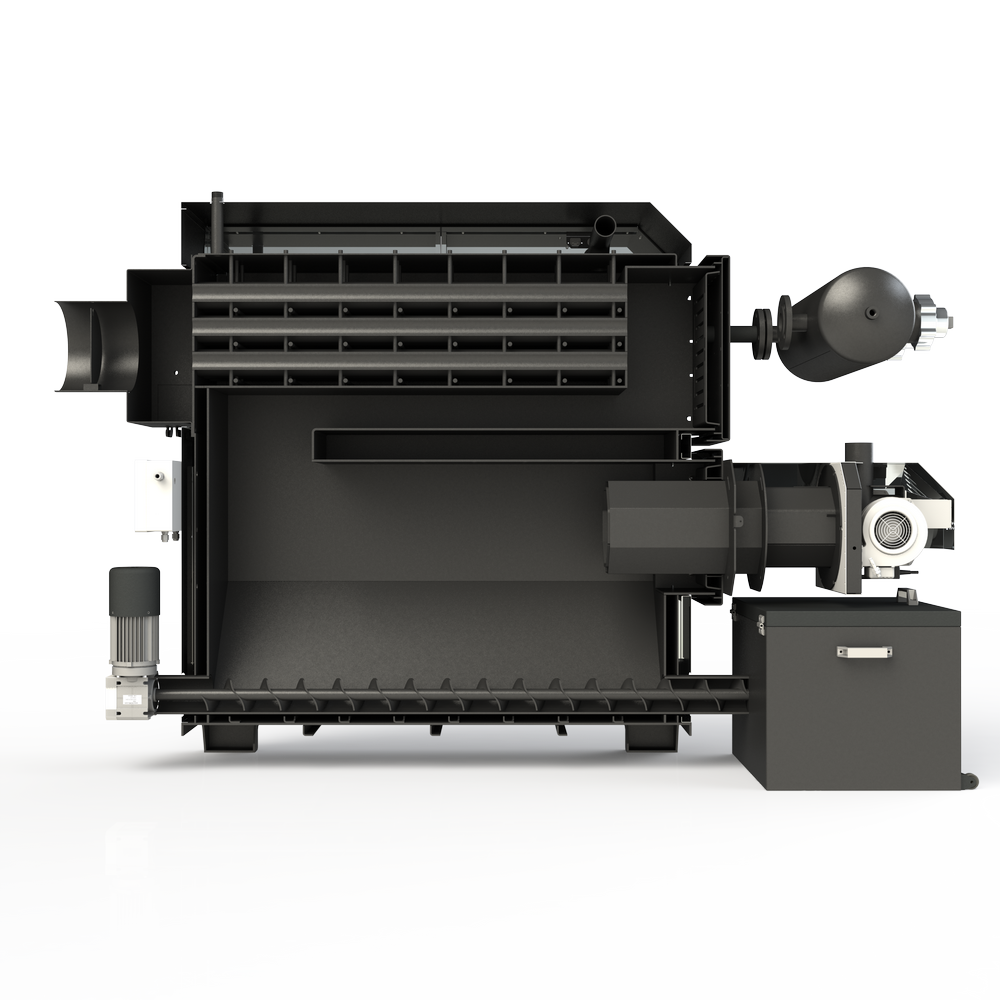

- Система шнекового золоудаления: встроенный шнек для автоматической транспортировки золы в откатной контейнер увеличивает периоды между чистками, снижая необходимость ручного обслуживания.

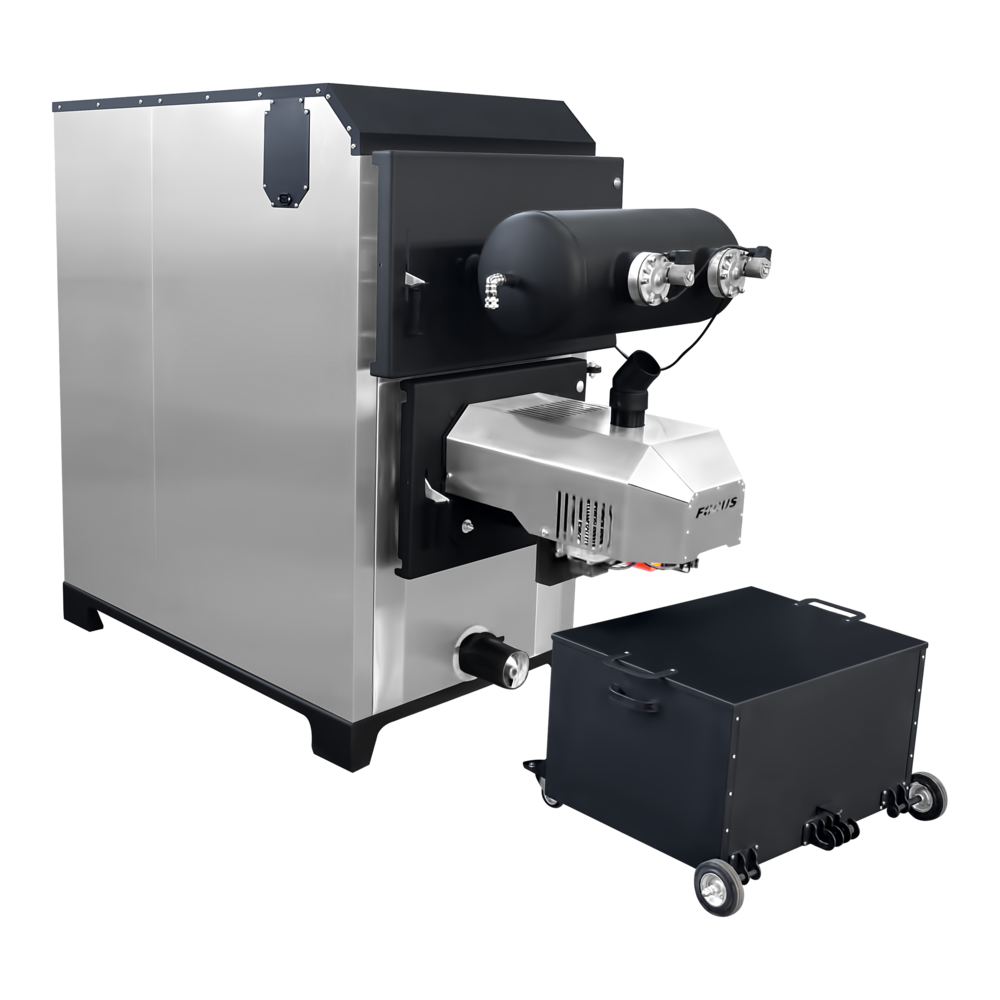

- Пневматическая очистка теплообменника: обеспечивает очищение теплообменных поверхностей с помощью пневмоустройства, оснащенного ресивером, и управляется автоматикой котла.

- Откатной контейнер: зольник высокой емкости с системой перемещения золы в контейнер для облегчения ее утилизации.

Эффективность и теплосъём

- Гибридный теплообменник: состоит из пластинчатой и жаротрубной частей. Пластинчатая часть снимает первичное тепловое напряжение и осаждает тяжелые частицы из топлива, а развитая конвективная жаротрубная часть обеспечивает высокий КПД.

- Оптимизирован для агропеллет: конструкция разрабатывалась с учетом работы на высокозольном топливе (зольность до 10%), что повышает экономичность и рентабельность котла при использовании доступного сырья.

Простота монтажа и эксплуатации

- Быстрые соединения Victaulic: удобная система соединений, не требующая сварки, позволяет оперативно монтировать котел и допускает небольшие перекосы при установке.

- Дополнительная обвязка (опционально): для защиты от холодной обратки котел может комплектоваться трехходовым или четырехходовым клапаном с насосами IMP Pumps, что продлевает срок службы и улучшает теплосъём.

Преимущества встроенной пеллетной горелки

Горелка ТМ «FOCUS» адаптирована как для древесных, так и агропеллет. Ее основные элементы включают:

- Автоматический розжиг: японские керамические свечи для бесконтактного воздушного розжига.

- Подвижный моноколосник: облегчает перемещение золы в зольник.

- Температурный и инфракрасный датчики: контролируют уровень излучения и температуру, повышая безопасность и устойчивость работы горелки.

- Пропорции воздуха: настраиваемое соотношение первичного и вторичного воздуха улучшает процесс горения.

Материалы и долговечность

- Корпус и теплообменник: изготовлены из конструкционной стали 09Г2С, а для теплоизоляции используется базальтовая вата толщиной 50 мм, что способствует снижению теплопотерь.

- Удобство обслуживания: большой дверной проем для легкого доступа к теплообменнику и зольнику, регулируемые петли и замки обеспечивают плотное прилегание дверей.

Пелетный котел FOCUS 120 кВт подходит как для частных домовладений, так и для коммерческих объектов, обеспечивая надежное, автоматизированное отопление при минимальных затратах на обслуживание.

Функции и комплектация

Функционал пеллетного котла 120 кВт FOCUS (30-120 кВт):

- мощность с динамической регулировкой 30 кВт – 120 кВт;

- 5 стандартных уровней безопасности;

- автоматическая работа: розжиг, тушение, очистка в процессе работы от золы и при гашении;

- автоматическое шнековое золоудаление во внешний контейнер;

- автоматическая пневматическая очистка топки котла в зоне теплообменника;

- автоматическая очистка горелки в общую систему золоудаления котла;

- керамическая свеча розжига, дублирование свечей розжига;

- низкое энергопотребление (800 Вт);

- PID-регулирование (возможность точного регулирования горелкой с помощью аналогового управляющего сигнала, в том числе, в рамках технологии «умный дом»);

- подвижный, съёмный моно-колосник из хромистого сплава для механической очистки горелки;

- управление насосами (горячая водоподготовка и отопление);

- работа с комнатным термостатом и интернет-модулем;

- работа с погодным регулированием;

- встроенный зольный фильтр.

Пелетный котел FOCUS 120 кВт соответствует ГОСТ32452-2013 (EN 15270:2007). Предоставляется гарантия 12 месяцев.

Комплект поставки:

- пелетный котел FOCUS 120 кВт в сборе с горелкой, система шнекового золоудаления, система пневматического золоудаления;

- откатной контейнер сбора золы — комплект;

- интернет-модуль EcoNet;

- датчик погоды;

- датчик температуры дым газов;

- датчик температуры обратки котла;

- подающий шнековый транспортер – 2 м;

- гофрированная труба ПВХ – 1 м;

- контроллер по управлению пеллетной горелкой;

- документация.

Оборудование для пеллетных котельных

Устройства и модули, повышающие уровень автономности системы отопления:

- комплекты обвязки с трехходовым или четырехходовым клапаном интегрированные в систему управления котла;

- бункеры для хранения и подачи пеллеты;

- комнатный сенсорный регулятор EcoSter;

- дополнительные датчики температуры.

Проконсультируйтесь по особенностям развертывания отопительных контуров и подключения у наших специалистов.

Габариты

Указаны в каждой позиции отдельно.

Диаметр дымохода

250 мм

Требования к помещению котельной

При проектировании необходимо придерживаться требований:

- МДНАОП 0.001.26-96;

- ДБН В.2.5-ХХ: 20ХХ;

- СНиП 2.04.05-91 «Отопление, вентиляция и кондиционирование»;

- СНиП II-35-76 «Котельные установки».

Интересно почитать

Процесс эксплуатации пеллетной горелки в деталях

Какой твердотопливный котел купить для производства

Отзывы

Отзывов пока нет.