Пеллетный котел 120 кВт FOCUS: ваш простой переход на автоматическое отопление

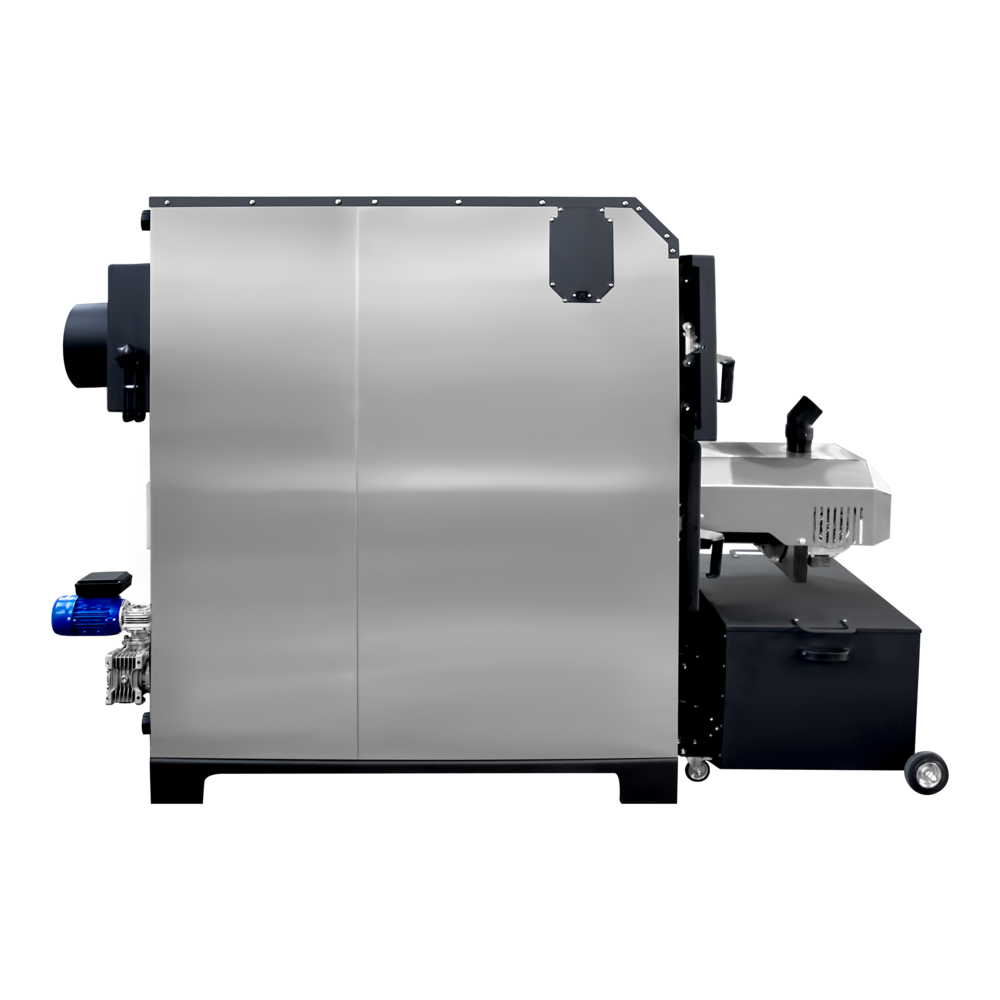

Автоматизированный пеллетный котел 120 кВт FOCUS — это промышленный котел с встроенной пеллетной горелкой, разработанный для высокоэффективной работы с агропеллетами и топливом с высокой зольностью. Он оснащен системой автоматического золоудаления и отличается минимальными требованиями к ручной очистке.

Пеллетный котел 120 кВт FOCUS: основные характеристики и преимущества

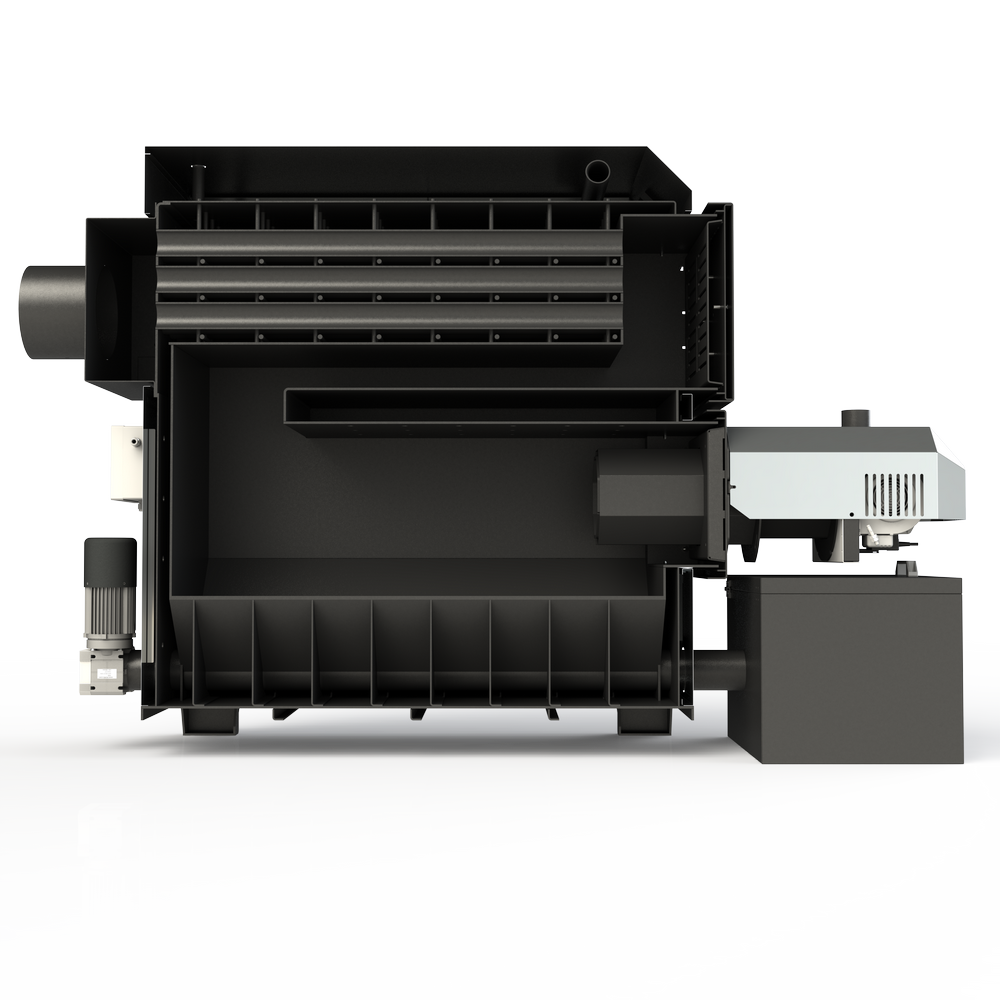

- Зольник увеличенной емкости: Специально рассчитан для работы с высокозольным топливом, таким как агропеллеты, позволяя значительно увеличить периоды между очистками.

- Шнековая система золоудаления: Встроенный механизм автоматической подачи золы из зольника в откатной контейнер минимизирует ручной труд по обслуживанию.

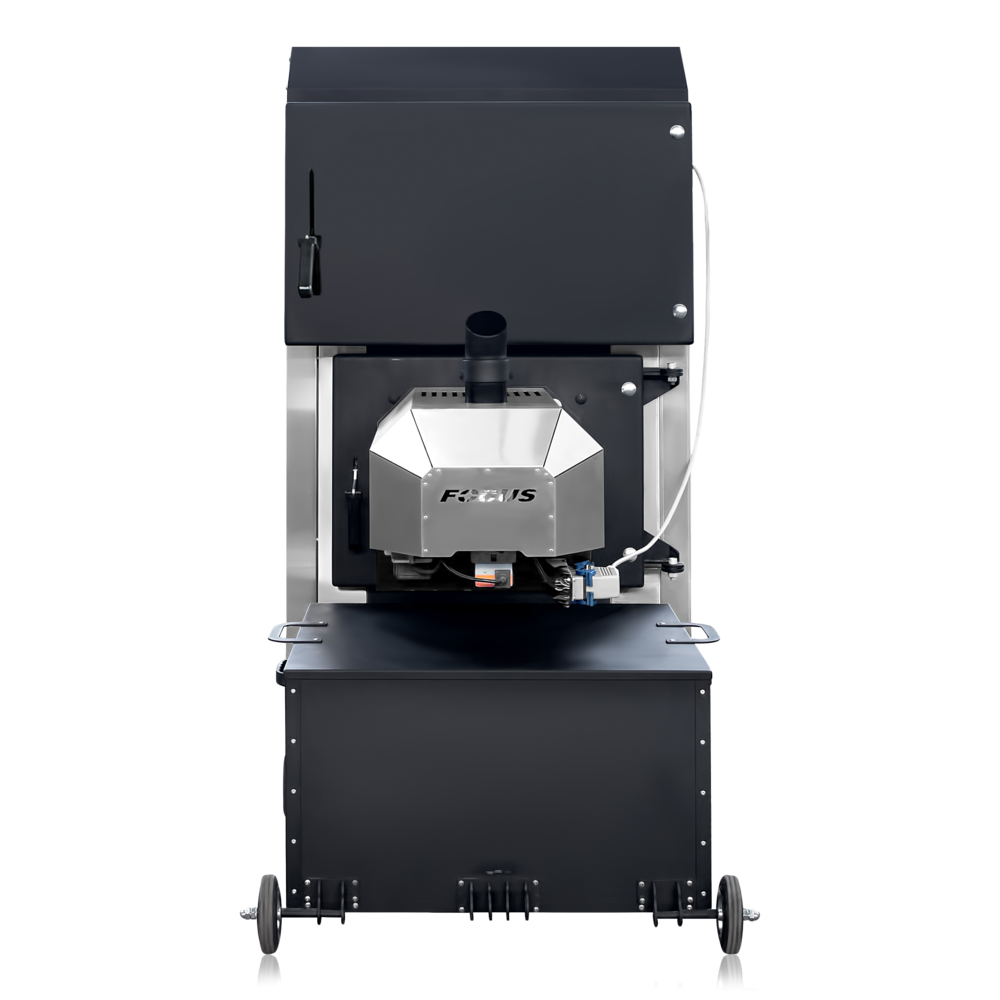

- Горелка FOCUS с высоким КПД: Оптимизирована для работы с древесной и агропеллетой, что делает котел универсальным и экономически выгодным. Система автоматического розжига и регулировки подачи воздуха повышает эффективность горения.

- Гибридный теплообменник: Пластинчатый и жаротрубный теплообменник обеспечивают высокоэффективную передачу тепла. Пластинчатый элемент снимает тепловое напряжение факела и фильтрует тяжелые частицы, снижая уровень загрязнения.

- Удобное обслуживание: Пеллетный котел 120 кВт FOCUS оснащен большими дверцами, которые позволяют легко очищать теплообменные поверхности. Зольная камера расположена перед дымоходом для быстрого доступа.

- Пеллетная горелка на дверце: Установлена на усиленных петлях, что облегчает обслуживание. Горелка легко откатывается вместе с дверцей.

- Защита от холодной обратки: При дополнительной комплектации котел можно оснастить трехходовыми клапанами и насосами IMP Pumps, что защитит его от конденсации и увеличит КПД на 30%.

- Простота монтажа: Пеллетный котел 120 кВт FOCUS оборудован системой быстрых соединений Victaulic, которая обеспечивает быстрое и качественное соединение без необходимости симметричной затяжки.

- Модульность и масштабируемость: Котел можно использовать в каскадных системах для увеличения мощности до 2,5 МВт, что делает его идеальным для крупных промышленных объектов.

Дополнительные особенности:

- Материалы: Теплообменная часть выполнена из конструкционной стали 09Г2С толщиной 6 мм, а внешняя оболочка — из нержавеющей стали AISI201.

- Теплоизоляция: Базальтовая минеральная вата толщиной 50 мм.

- Автоматическая очистка горелки: Горелка очищается в общую систему золоудаления, обеспечивая беспрерывную работу на высокозольных пеллетах.

- Безопасность: Встроенные датчики температуры и пламени обеспечивают контроль и защиту от аварийных ситуаций. Линия подачи топлива оснащена механизмом разрыва для повышения безопасности эксплуатации.

Преимущества пеллетной горелки FOCUS:

- Автоматический розжиг с использованием японских керамических свечей.

- Подвижный моноколосник, обеспечивающий равномерное горение и удаление золы.

- Точный контроль воздуха для эффективного сжигания топлива с высокоэффективной подачей первичного и вторичного воздуха.

Автоматизированный пеллетный котел 120 кВт FOCUS — это надёжное решение для промышленных и коммерческих объектов, требующих эффективного и экономичного отопления на различных видах пеллетного топлива, включая агропеллеты.

Функции и комплектация

Функционал пеллетный котел 120 кВт FOCUS (20-120 кВт):

- диапазон мощности 20 кВт – 120 кВт;

- 5 уровней безопасности;

- полная автоматика: розжиг, тушение, авто-очистка, очистка от основной золы при гашении;

- автоматическое шнековое удаление золы во внешний золоприёмник;

- автоматическая очистка горелки в общую систему удаления золы;

- керамическая свеча розжига, дубликат свечей розжига;

- низкая потребность в электричестве (800 Вт);

- PID-регулирование (возможность точного регулирования горелкой с помощью аналогового управляющего сигнала, в том числе, в рамках технологии «умный дом»);

- подвижный, съёмный моно-колосник из сплава хрома для очистки горелки механическим способом;

- управление насосами (ГВС и отопление);

- работа с комнатными устройствами и модулем интернет-доступа;

- погодный регулятор;

- встроенный зольный фильтр в виде пластинчатого теплообменника.

Предложенный пеллетный котел 120 кВт FOCUS соответствует нормам ГОСТ32452-2013 (EN 15270:2007). Гарантия 12 месяцев.

Комплект поставки:

- пеллетный котел 120 кВт FOCUS в сборе с горелкой, система шнекового золоудаления;

- откатной контейнер сбора золы — комплект;

- интернет-модуль EcoNet;

- датчик погоды;

- датчик температуры дым газов;

- датчик температуры обратки котла;

- подающий шнековый транспортер – 2 м;

- гофрированная труба ПВХ – 1 м;

- контроллер по управлению пеллетной горелкой;

- документация.

Оборудование для пеллетных котельных

Устройства и модули, повышающие уровень автономности системы отопления:

- комплекты обвязки с трехходовым или четырехходовым клапаном интегрированные в систему управления котла;

- бункеры для хранения и подачи пеллеты;

- комнатный сенсорный регулятор EcoSter;

- дополнительные датчики температуры.

Проконсультируйтесь по особенностям развертывания отопительных контуров и подключения у наших специалистов.

Габариты

Указаны в каждой позиции отдельно.

Диаметр дымохода

250 мм

Требования к помещению котельной

При проектировании необходимо придерживаться требований:

- МДНАОП 0.001.26-96;

- ДБН В.2.5-ХХ: 20ХХ;

- СНиП 2.04.05-91 «Отопление, вентиляция и кондиционирование»;

- СНиП II-35-76 «Котельные установки».

Интересно почитать

Процесс эксплуатации пеллетной горелки в деталях

Какой твердотопливный котел купить для производства

Отзывы

Отзывов пока нет.