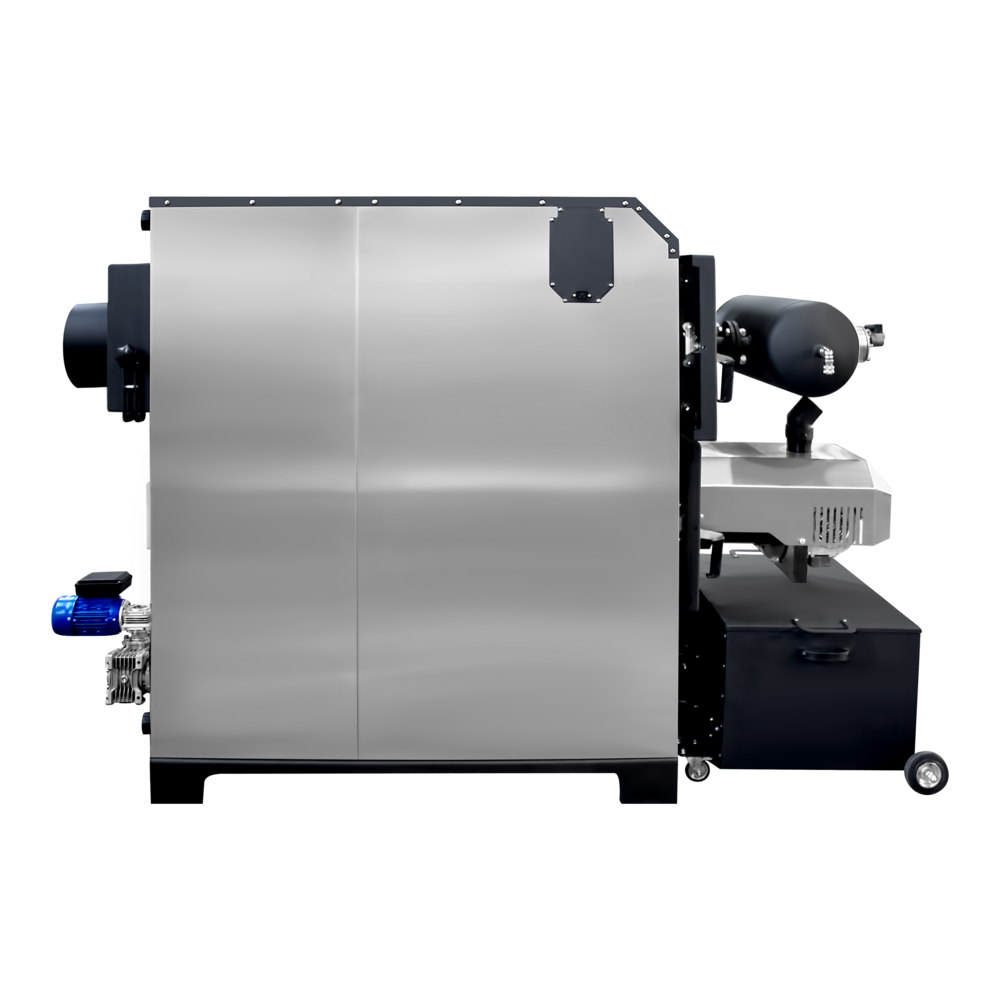

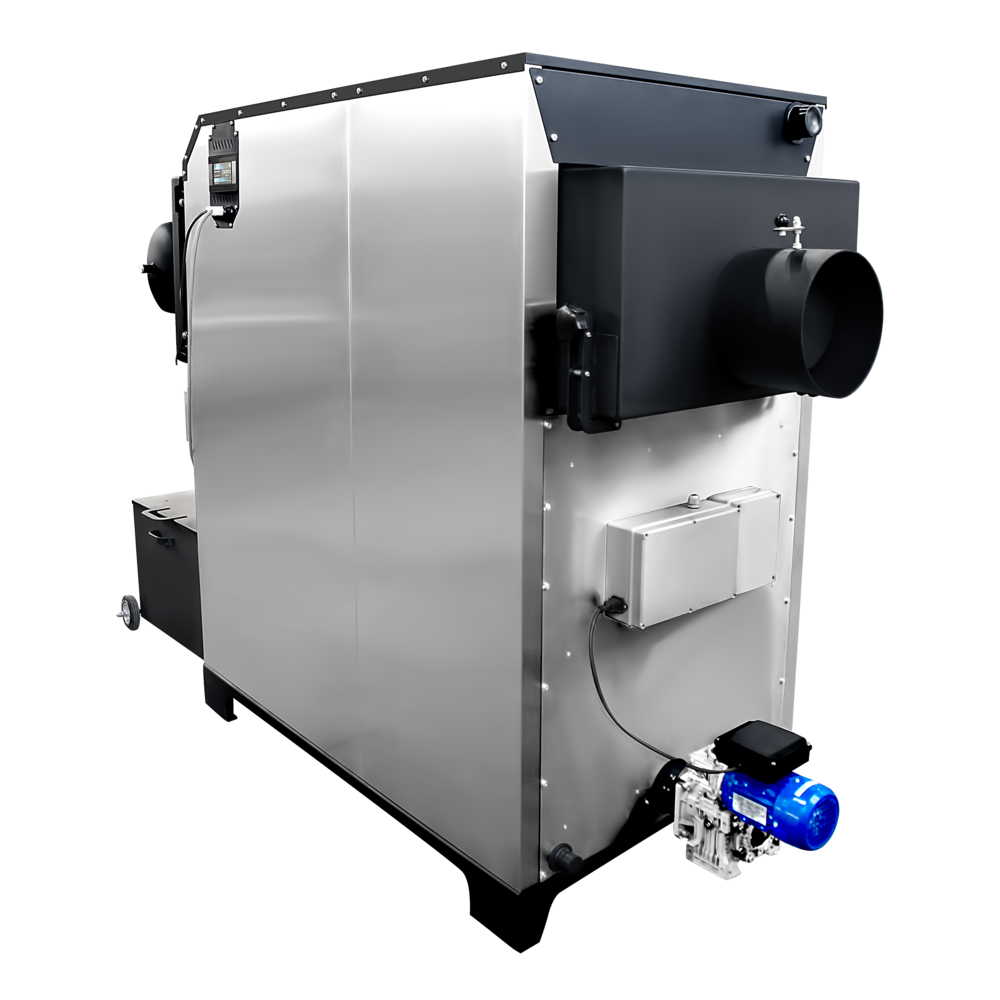

Автоматизированный пеллетный котел FOCUS 100 кВт с золоудалением и пневмоочисткой топки котла в зоне теплообменника (с климат-контролем)

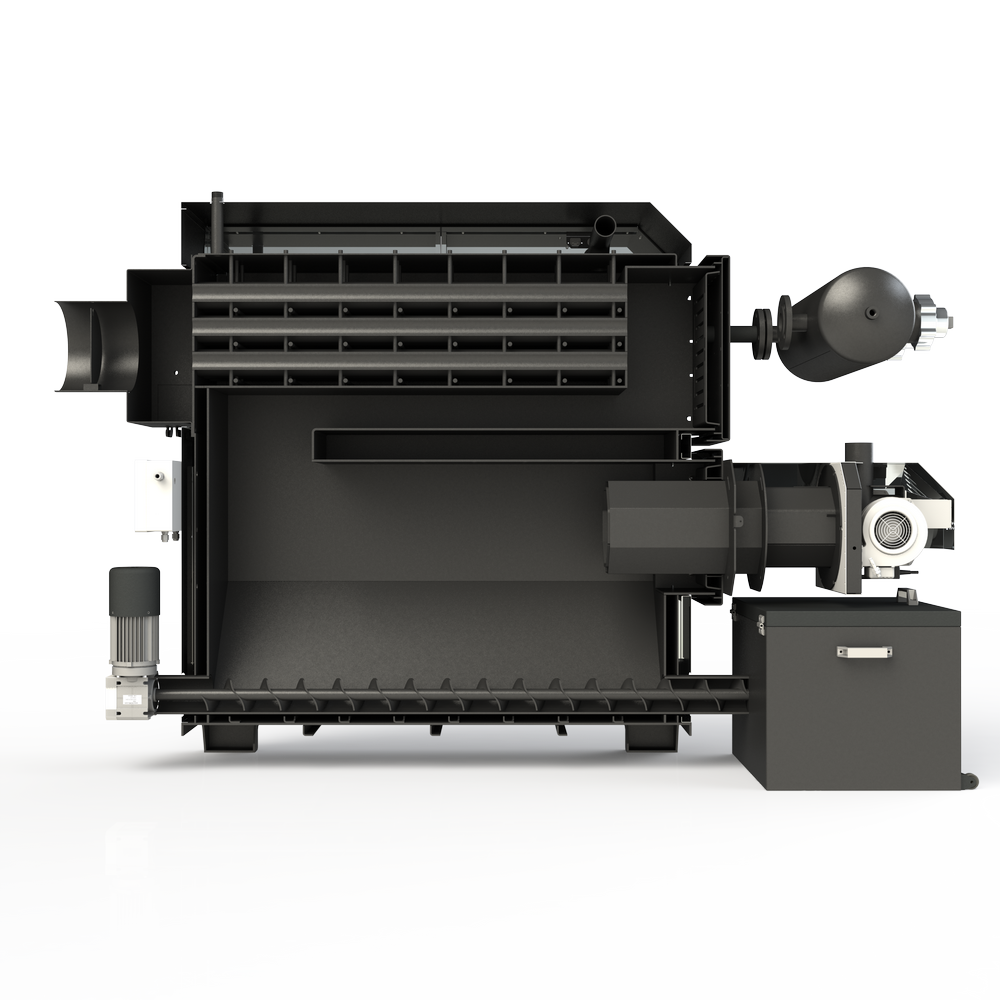

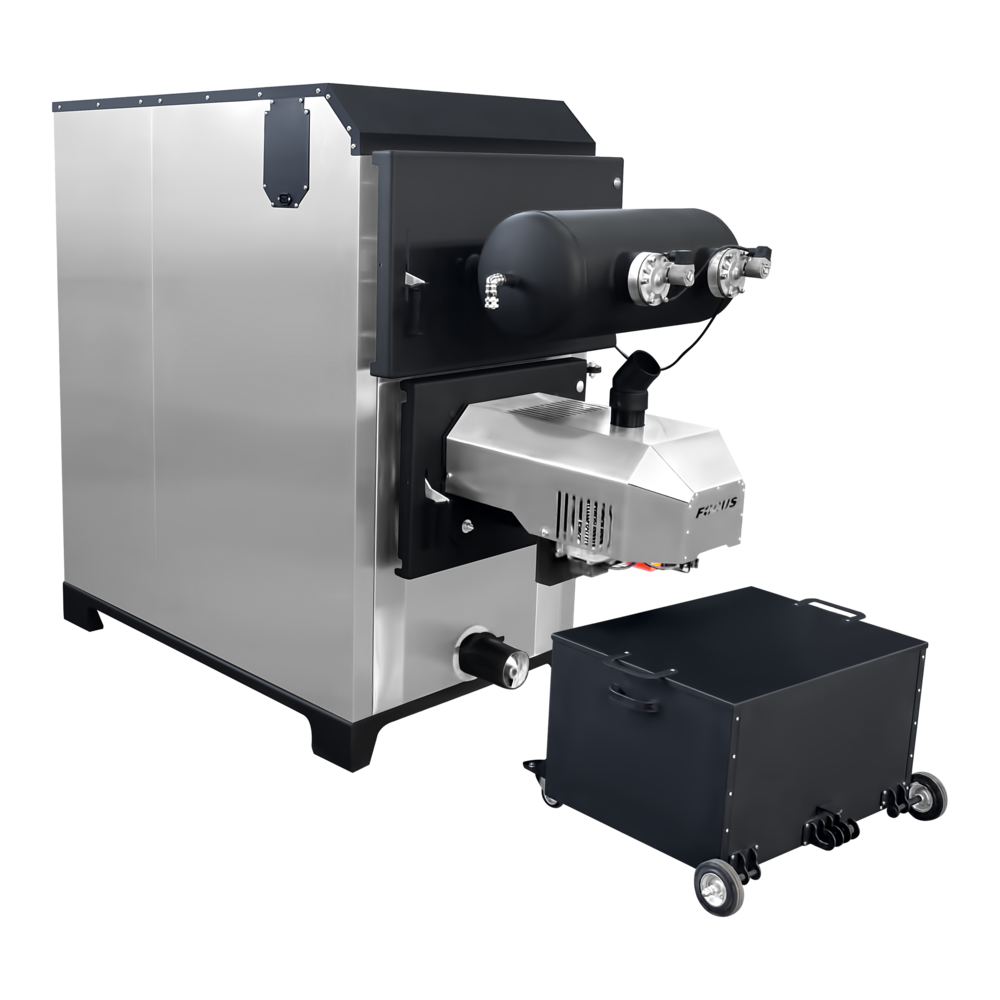

Автоматизированный пеллетный котел FOCUS 100 кВт представляет собой современное решение для отопления, обеспечивающее высокую эффективность и надежность. Котел оснащен встроенной промышленной пеллетной горелкой, системой шнекового золоудаления с откатным контейнером для сбора золы и системой пневматической очистки теплообменника с ресивером. Автоматика котла поддерживает управление циклами пневмоочистки, что делает его эксплуатацию максимально удобной и безопасной.

Основные преимущества

- Максимальный зольник: котел спроектирован для работы с высокозольным топливом, что значительно увеличивает его эффективность.

- Автоматизация процессов: встроенная система шнекового золоудаления и пневматической очистки позволяет существенно сократить ручной труд по очистке котла и теплообменника.

- Экономическая целесообразность: котел разработан с акцентом на эффективность теплосъема, особенно при использовании факельной пеллетной горелки на агро пеллете. Это обеспечивает быструю окупаемость оборудования.

Удобство обслуживания

- Обслуживание теплообменника: продуманное решение для легкой очистки теплообменника через широкий люк и зольную камеру перед дымоходом.

- Система быстрого монтажа: котел оборудован системой Victaulic, позволяющей быстро и удобно соединять элементы без необходимости сварки, что экономит время и усилия монтажника.

- Гибкость в использовании: котел может быть использован в каскадном режиме, что позволяет при необходимости безболезненно увеличивать мощность до 2.5 МВт.

Конструкция и материалы

- Качество материалов: котел выполнен из конструкционной стали 09Г2С, с толщиной стенок теплообменной части 6 мм и внешней оболочки 4 мм.

- Теплоизоляция: выполнена из базальтовой минеральной ваты толщиной 50 мм, что обеспечивает высокую теплоэффективность.

- Кожух из нержавеющей стали: для повышения долговечности и эстетичного внешнего вида используется шлифованная нержавеющая сталь AISI201.

Встроенная пеллетная горелка

Пеллетная горелка FOCUS позволяет использовать как чистую древесную пеллету, так и агропеллету с зольностью до 10%. Это дает возможность применять топливные гранулы из различных отходов, включая подсолнечник, кукурузу, гречку, рис и мебельные отходы.

Преимущества встроенной горелки:

- Автоматический розжиг: обеспечивается с помощью японских керамических свечей.

- Подвижный моноколосник: для ворошения горящего топлива и удаления высокозольного остатка в зольник.

- Датчики безопасности: встроенные датчики температуры шнека и пламени контролируют безопасность работы котла.

- Оптимизированное сжигание: подача первичного и вторичного воздуха позволяет достичь максимальной эффективности сжигания.

Пеллетный котел FOCUS 100 кВт является идеальным решением для отопления домов, небольших магазинов и удаленных объектов. Его автоматизация, высокие показатели эффективности и удобство обслуживания делают его выгодным выбором для пользователей, стремящихся к надежному и экономичному отоплению.

Функции и комплектация

Функционал пеллетного котла 100 кВт FOCUS (20-100 кВт):

- регулировка мощности в пределах 20 кВт – 100 кВт;

- 5 базовых уровней безопасности;

- автоматическая работа: розжиг, тушение, авто-очистка в режиме работы, очистка от основной золы при гашении;

- автоматическое шнековое золоудаление во внешний контейнер золоприёмник;

- автоматическая пневматическая очистка теплообменника котла;

- автоматическая очистка горелки в общую систему золоудаления котла;

- керамическая свеча розжига, дублирование свечей розжига;

- низкое энергопотребление (800 Вт);

- PID-регулирование (возможность точного регулирования горелкой с помощью аналогового управляющего сигнала, в том числе, в рамках технологии «умный дом»);

- подвижный, съёмный моно-колосник из хромистого сплава для механической очистки горелки;

- управление насосами (горячая водоподготовка и отопление);

- работа с комнатным термостатом и интернет-модулем;

- работа с погодным регулированием;

- встроенный зольный фильтр.

Пеллетный котел FOCUS 100 кВт соответствует ГОСТ32452-2013 (EN 15270:2007). Предоставляется гарантия 12 месяцев.

Комплект поставки:

- пеллетный котел FOCUS 100 кВт в сборе с горелкой, система шнекового золоудаления, система пневматического золоудаления;

- откатной контейнер сбора золы — комплект;

- интернет-модуль EcoNet;

- датчик погоды;

- датчик температуры дым газов;

- датчик температуры обратки котла;

- подающий шнековый транспортер – 2 м;

- гофрированная труба ПВХ – 1 м;

- контроллер по управлению пеллетной горелкой;

- документация.

Оборудование для пеллетных котельных

Устройства и модули, повышающие уровень автономности системы отопления:

- комплекты обвязки с трехходовым или четырехходовым клапаном интегрированные в систему управления котла;

- бункеры для хранения и подачи пеллеты;

- комнатный сенсорный регулятор EcoSter;

- дополнительные датчики температуры.

Проконсультируйтесь по особенностям развертывания отопительных контуров и подключения у наших специалистов.

Габариты

Указаны в каждой позиции отдельно.

Диаметр дымохода

250 мм

Требования к помещению котельной

При проектировании необходимо придерживаться требований:

- МДНАОП 0.001.26-96;

- ДБН В.2.5-ХХ: 20ХХ;

- СНиП 2.04.05-91 «Отопление, вентиляция и кондиционирование»;

- СНиП II-35-76 «Котельные установки».

Интересно почитать

Процесс эксплуатации пеллетной горелки в деталях

Какой твердотопливный котел купить для производства

Отзывы

Отзывов пока нет.